A kind of anti-corrosion steel plate for shelf heavy beam and its preparation method

A heavy-duty beam and anti-corrosion technology, which is applied in the field of steel plates and its preparation, can solve the problems of low-temperature toughness of steel plates, increased storage costs, and broken storage equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

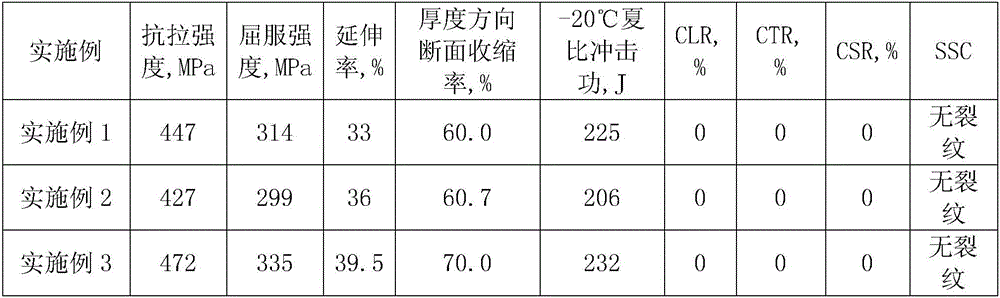

Examples

Embodiment 1

[0047] This embodiment is a kind of anti-corrosion steel plate used for the heavy beam of the shelf, the composition and mass percentage of the steel plate are: C: 0.7%, Mn: 0.1%, Si: 0.07%, P: 0.006%, S: 0.002 %, Nb: 0.043%, V: 0.07%, Ti: 0.5%, Al: 0.13%, N: 0.006%, H: 0.00020%, Cu: 0.07%, Cr: 3.7%, Mo: 0.43%, Lanthanum: 0.07 %, cerium: 0.03%, praseodymium: 0.05%, the balance is Fe and unavoidable impurities;

[0048] The first phase in the steel plate is ferrite, the second phase is pearlite, the volume percentage of the second phase from the surface to 1 / 4 thickness is 3.1%, and the volume percentage of the second phase from 1 / 4 thickness to the center is 7.3%, And there is no band structure; the average grain diameter of ferrite from the surface to 1 / 4 thickness of the steel plate is 5.5 μm, the average diameter of pearlite clusters is 4.0 μm, and the average grain diameter of ferrite from 1 / 4 thickness to the center is 6.0 μm, and the average diameter of pearlite cluster...

Embodiment 2

[0059] This embodiment is a corrosion-resistant steel plate used for heavy beams of shelves. The composition and mass percentage of the steel plate are: C: 0.8%, Mn: 0.2%, Si: 0.08%, P: 0.007%, S: 0.003%, Nb: 0.044%, V: 0.08%, Ti: 0.6%, Al: 0.14%, N: 0.001%, H: 0.0001%, Cu: 0.08%, Cr: 3.8%, Mo: 0.44%, Lanthanum: 0.08%, Cerium: 0.04%, Praseodymium: 0.06%, the balance is Fe and unavoidable impurities;

[0060] The first phase in the steel plate is ferrite, the second phase is pearlite, the volume percentage of the second phase from the surface to 1 / 4 thickness is 3.2%, and the volume percentage of the second phase from 1 / 4 thickness to the center is 7.4%, And there is no band structure; the average grain diameter of ferrite from the surface to 1 / 4 thickness of the steel plate is 5.6 μm, the average diameter of pearlite clusters is 4.1 μm, and the average grain diameter of ferrite from 1 / 4 thickness to the center is 6.1 μm, and the average diameter of pearlite clusters is 8.1 μm...

Embodiment 3

[0071] This embodiment is a corrosion-resistant steel plate used for heavy beams of shelves. The composition and mass percentage of the steel plate are: C: 0.9%, Mn: 0.3%, Si: 0.09%, P: 0.008%, S: 0.004%, Nb: 0.045%, V: 0.09%, Ti: 0.7%, Al: 0.15%, N: 0.002%, H: 0.00015%, Cu: 0.09%, Cr: 3.9%, Mo: 0.45%, Lanthanum: 0.09%, Cerium: 0.05%, Praseodymium: 0.07%, the balance is Fe and unavoidable impurities;

[0072] The first phase in the steel plate is ferrite, the second phase is pearlite, the volume percentage of the second phase from the surface to 1 / 4 thickness is 3.3%, and the volume percentage of the second phase from 1 / 4 thickness to the center is 7.5%, And there is no band structure; the average grain diameter of ferrite from the surface to 1 / 4 thickness of the steel plate is 5.7 μm, the average diameter of pearlite clusters is 4.2 μm, and the average grain diameter of ferrite from 1 / 4 thickness to the center is 6.2 μm, and the average diameter of pearlite clusters is 8.2 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com