Stainless steel for security doors and heat treatment method of stainless steel

A heat treatment method and stainless steel technology, which is applied in the field of stainless steel and its heat treatment, can solve the problems of fracture, low-temperature toughness of stainless steel, etc., and achieve the effect of improving corrosion resistance and improving steel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

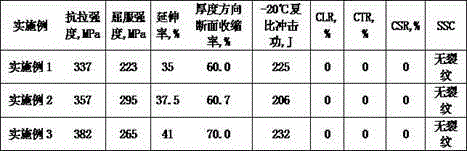

Embodiment 1

[0045] This embodiment is a stainless steel used for anti-theft doors. The composition and mass percentage of the stainless steel are: C: 0.08%, Mn: 1.21%, Si: 0.14%, P: 0.003%, S: 0.001%, Mg: 0.093 %, V: 0.06%, Ti: 1.8%, Al: 1.5%, Cu: 0.05%, Cr: 23.7%, Ni: 16.5%, Mo: 0.25%, lanthanide rare earth elements 0.12%, the balance is Fe and not Impurities to avoid;

[0046] Wherein the chemical composition mass percentage content of lanthanide is: Nd: 13%, Ce: 11%, Er: 8%, Pr: 6%, Pm: Dy: 1%, the balance is La;

[0047] In the stainless steel for anti-theft doors, the number density of carbides is greater than 0.9 pieces / μm 2 , the ratio of the number of coarse carbides with a particle size of 0.4 μm or more to the carbides is less than 0.1; the corrosion resistance of the corrosion-resistant steel for the window frame is ≤0.004 mm / years, and the corrosion resistance is ≤0.005 mm / year under alkaline conditions with a pH value of 7~10.

[0048] The aforementioned heat treatment me...

Embodiment 2

[0055] This embodiment is a stainless steel used for anti-theft doors. The composition and mass percentage of the stainless steel are: C: 0.10%, Mn: 1.25%, Si: 0.15%, P: 0.004%, S: 0.001%, Mg: 0.094 %, V: 0.06%, Ti: 1.9%, Al: 1.7%, Cu: 0.06%, Cr: 23.8%, Ni: 16.6%, Mo: 0.24%, lanthanide rare earth elements 0.16%, the balance is Fe and not Impurities to avoid;

[0056] Wherein the chemical composition mass percentage of lanthanide elements is: Nd: 15%, Ce: 15%, Er: 11%, Pr: 6%, Pm: 1%, and the balance is La;

[0057] In the stainless steel for anti-theft doors, the number density of carbides is greater than 0.9 pieces / μm 2 , the ratio of the number of coarse carbides with a particle size of 0.4 μm or more to the carbides is less than 0.1; the corrosion resistance of the corrosion-resistant steel for the window frame is ≤0.004 mm / years, and the corrosion resistance is ≤0.005 mm / year under alkaline conditions with a pH value of 7~10.

[0058] The aforementioned heat treatment ...

Embodiment 3

[0065] This embodiment is a stainless steel used for anti-theft doors. The composition and mass percentage of the stainless steel are: C: 0.11%, Mn: 1.29%, Si: 0.16%, P: 0.005%, S: 0.002%, Mg: 0.095 %, V: 0.06%, Ti: 1.8%, Al: 1.7%, Cu: 0.05%, Cr: 23.9%, Ni: 16.7%, Mo: 0.25%, lanthanide rare earth elements 0.18%, the balance is Fe and not Impurities to avoid;

[0066] Wherein the chemical composition mass percentage of lanthanides is: Nd: 17%, Ce: 18%, Er: 14%, Pr: 9%, Pm: 4%, Dy: 2%, and the balance is La;

[0067] In the stainless steel for anti-theft doors, the number density of carbides is greater than 0.9 pieces / μm 2 , the ratio of the number of coarse carbides with a particle size of 0.4 μm or more to the carbides is less than 0.1; the corrosion resistance of the corrosion-resistant steel for the window frame is ≤0.004 mm / years, and the corrosion resistance is ≤0.005 mm / year under alkaline conditions with a pH value of 7~10.

[0068] The aforementioned heat treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com