Small device for silk reeling technology

A technology, silk technology, applied in the direction of silk reeling, etc., can solve problems such as difficulty in ensuring uniformity, complicated procedures, and long time consumption, and achieve the effect of solving silk messy silk, subtracting multiple processes, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

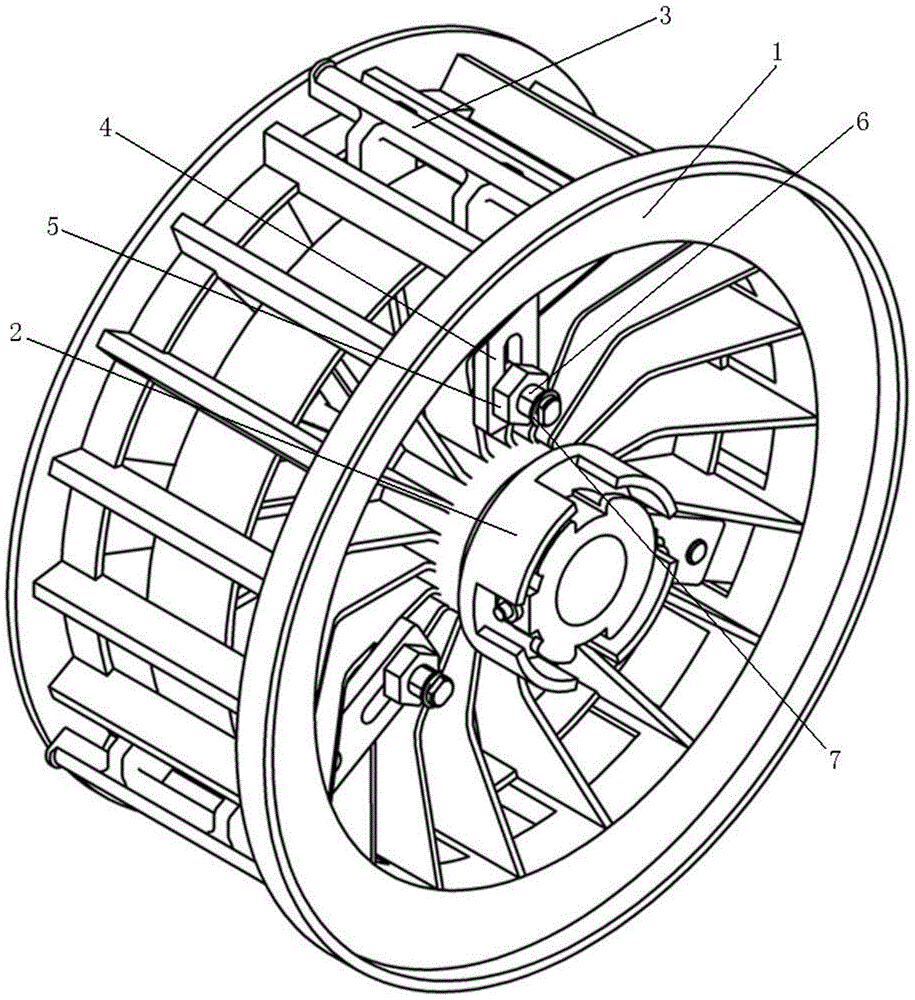

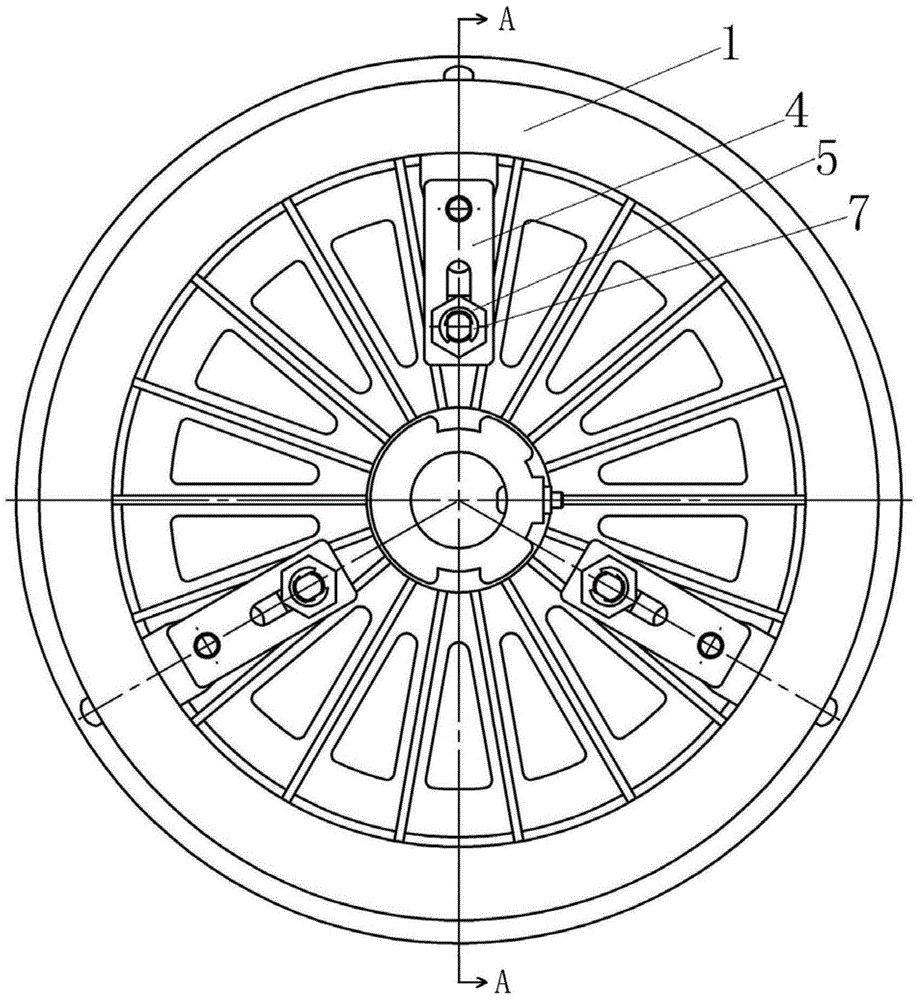

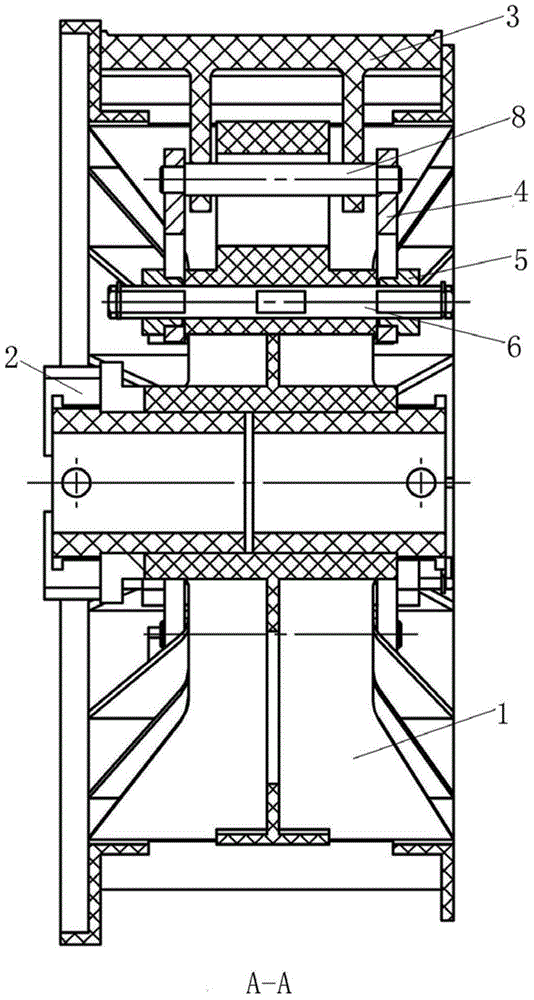

[0031] The present invention will be further described below according to the accompanying drawings.

[0032] Such as Figure 1 to Figure 3 As shown, a sheath 2 is embedded in the center of the small Yu body 1, and a number of supporting wire devices are evenly distributed on the outer edge of the small Yu body 1 circle; The side module, the fixed screw, and the adjustment nut, the fixed screw 6 runs through the small body 1 from front to back, and the two ends of the fixed screw 6 are respectively located at the front and rear of the small body 1; the front and rear ends of the fixed screw 6 are respectively connected One end of the brace module 4 and the other end of the brace module 4 on the front and rear sides are connected by a support column 8; the support column 8 between the brace modules 4 on the front and rear sides is covered with the lower end of the brace frame 3 , the upper end of the support wire frame 3 is mounted on the outer edge of the small Yu body 1; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com