A mobile cold stacker

A cold stacker and mobile technology, applied in the field of textile dyeing and finishing, can solve the problems of inconvenient operation, high production and operation cost, and large space occupation, and achieve the effect of convenient use and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further elaborated below by means of the accompanying drawings and examples.

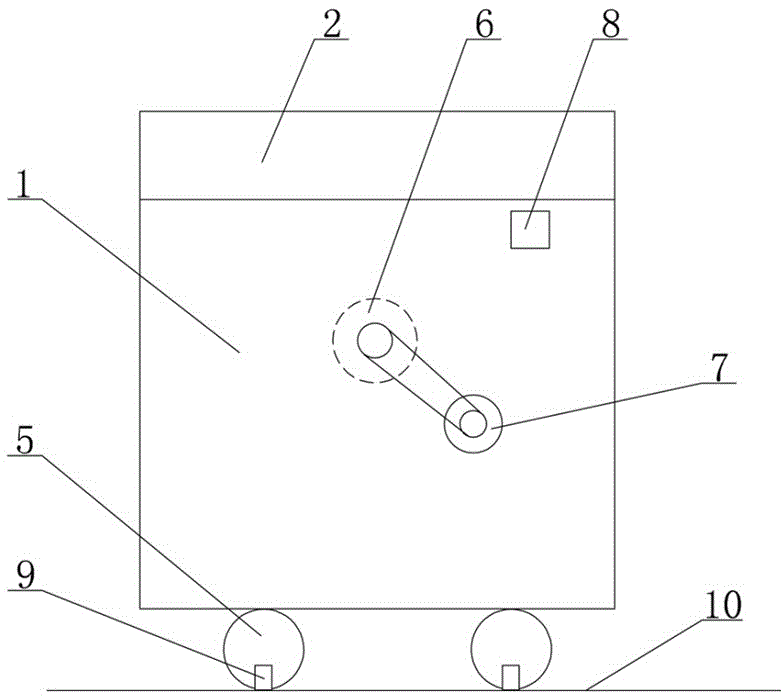

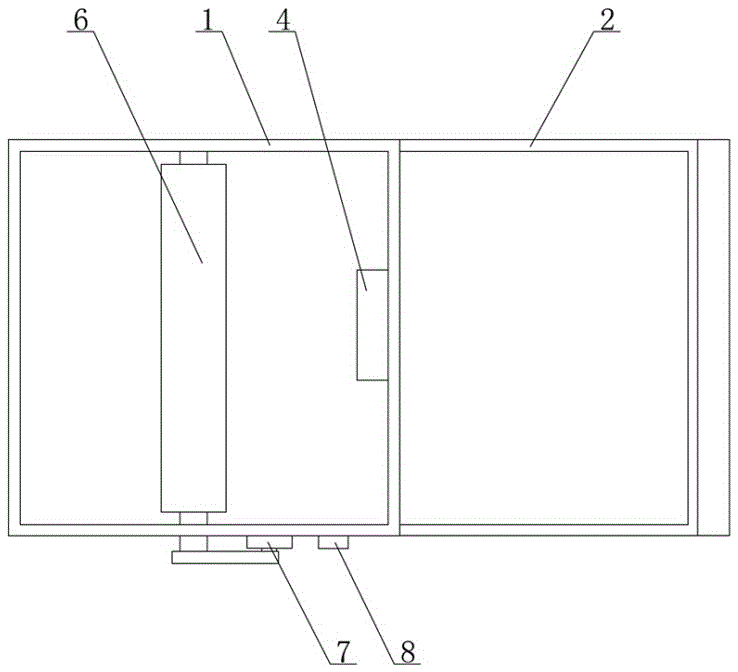

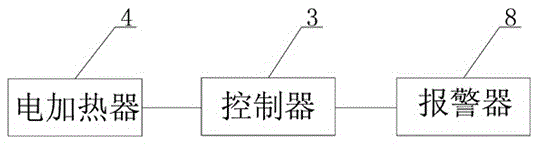

[0014] like Figure 1 to Figure 3 Shown: a mobile cold stacker, including an insulation box 1 with an open upper end, a sealing cover 2, a controller 3, and an electric heater 4. The sealing cover 2 can be closed on the opening of the heat preservation box 1, and is used for sealing and heat preservation of the heat preservation box 1. The bottom of the heat preservation box 1 is provided with moving wheels 5 . The inside of the heat preservation box 1 is provided with a lapping roller 6 , which is used for winding the cotton layer and is supported on the inner side wall of the heat preservation box 1 . The outside of the heat preservation box 1 is provided with a drive motor 7 for driving the roll roll 6 to rotate, and the drive motor 7 is linked with the roll roll 6 . The electric heater 4 is arranged inside the insulated box 1 and is connected to the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com