Anti-overflow inspection well

An inspection well and anti-overflow technology, applied in water conservancy projects, underwater structures, artificial islands, etc., can solve the problems of easy overflow, poor drainage of inspection wells, and inconvenient dredging operations, saving materials and reducing mold opening. Cost, effect of guaranteed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

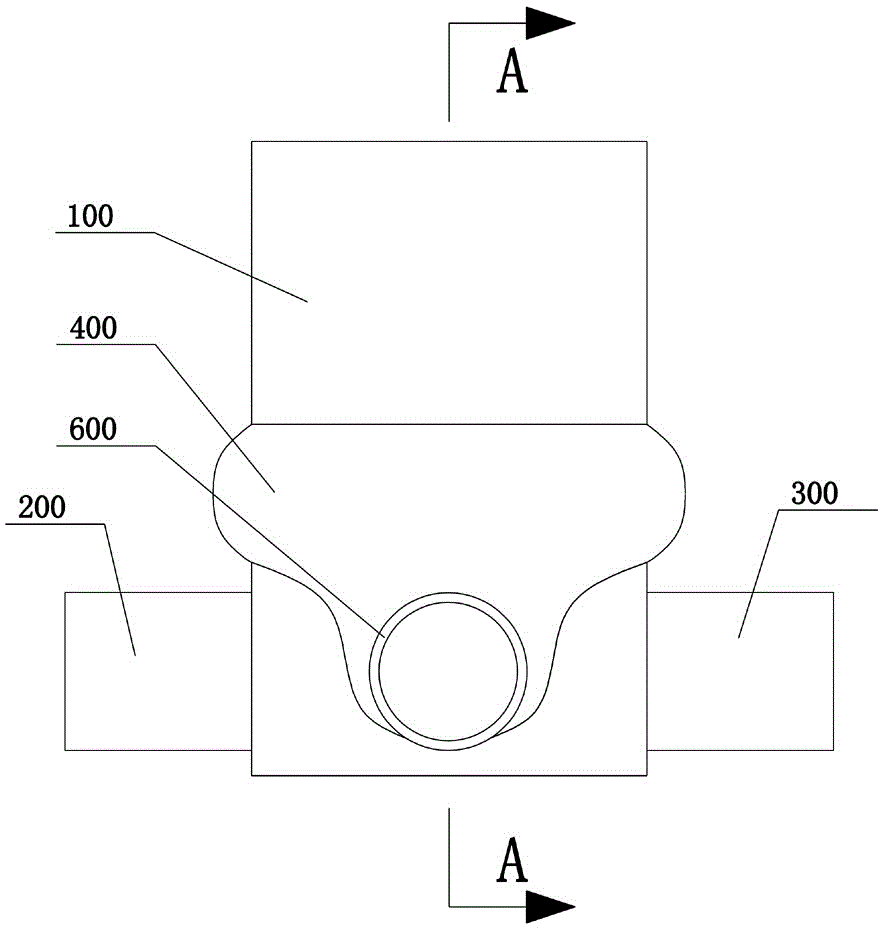

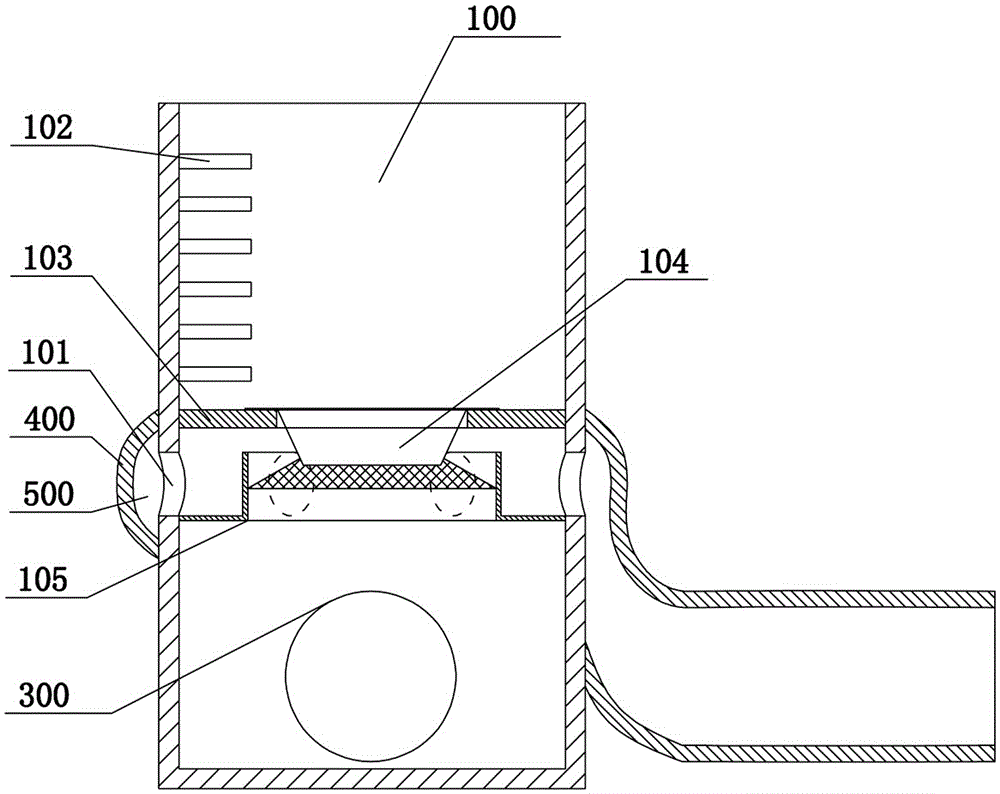

[0027] Such as figure 1 As shown, an overflow-proof inspection well includes a shaft 100 , a water outlet pipe 200 , a water inlet pipe 300 , a water storage jacket 400 and an overflow pipe 600 . The water outlet pipe 200 and the water inlet pipe 300 communicate with each other at the bottom of the wellbore 100 . The water storage jacket 400 is sleeved on the outer wall of the shaft 100 to form a water storage cavity 500 . The overflow pipe 600 is connected to the water storage jacket 400 and communicates with the water storage chamber 500 .

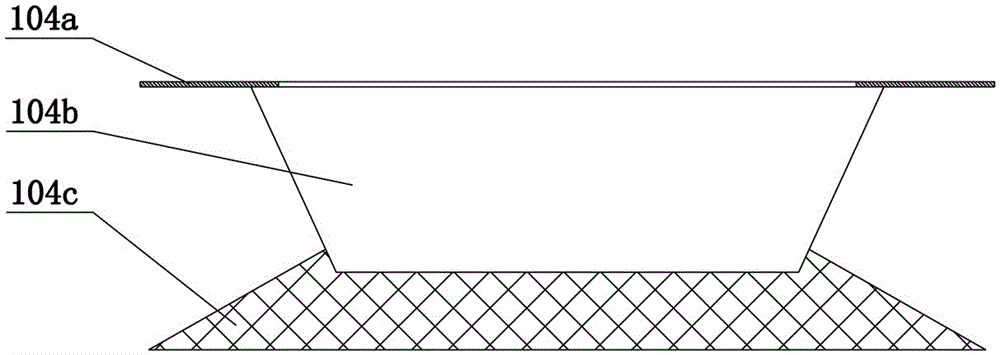

[0028] Such as figure 2 As shown, the side wall of the shaft 100 is provided with an overflow port 101; the overflow port 101 is located above the water outlet pipe 200 and the water inlet pipe 300; interconnected.

[0029] When the amount of rainwater is large, the drainage of the inspection well is not smooth, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com