Integrally-inserted conical sealing reversal valve

A conical surface sealing and plug-in technology, which is applied in mining equipment, earthwork drilling, pillars/supports, etc., can solve problems such as underground maintenance, production, replacement difficulties, sealing surface leakage, and sealing structure defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

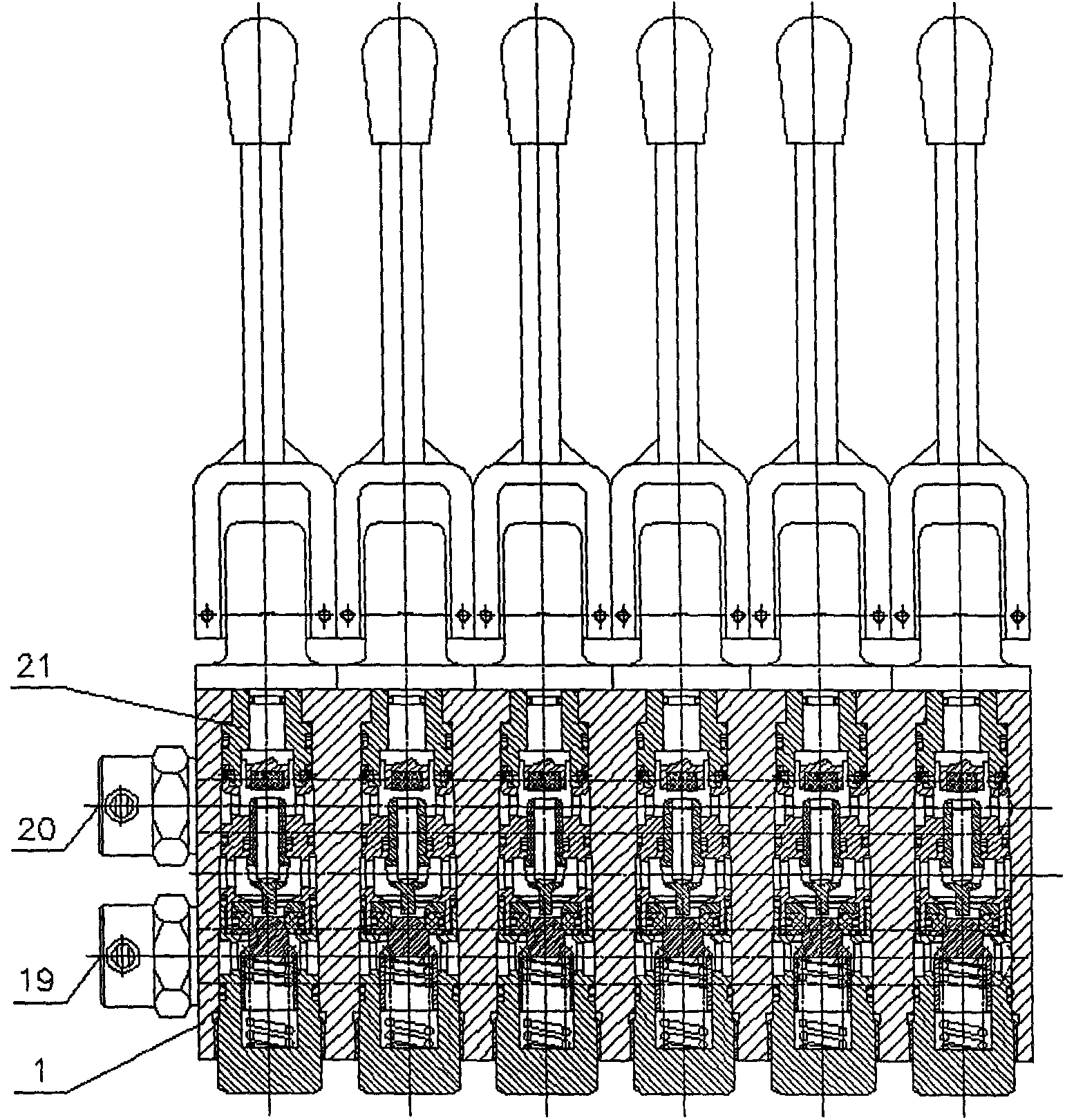

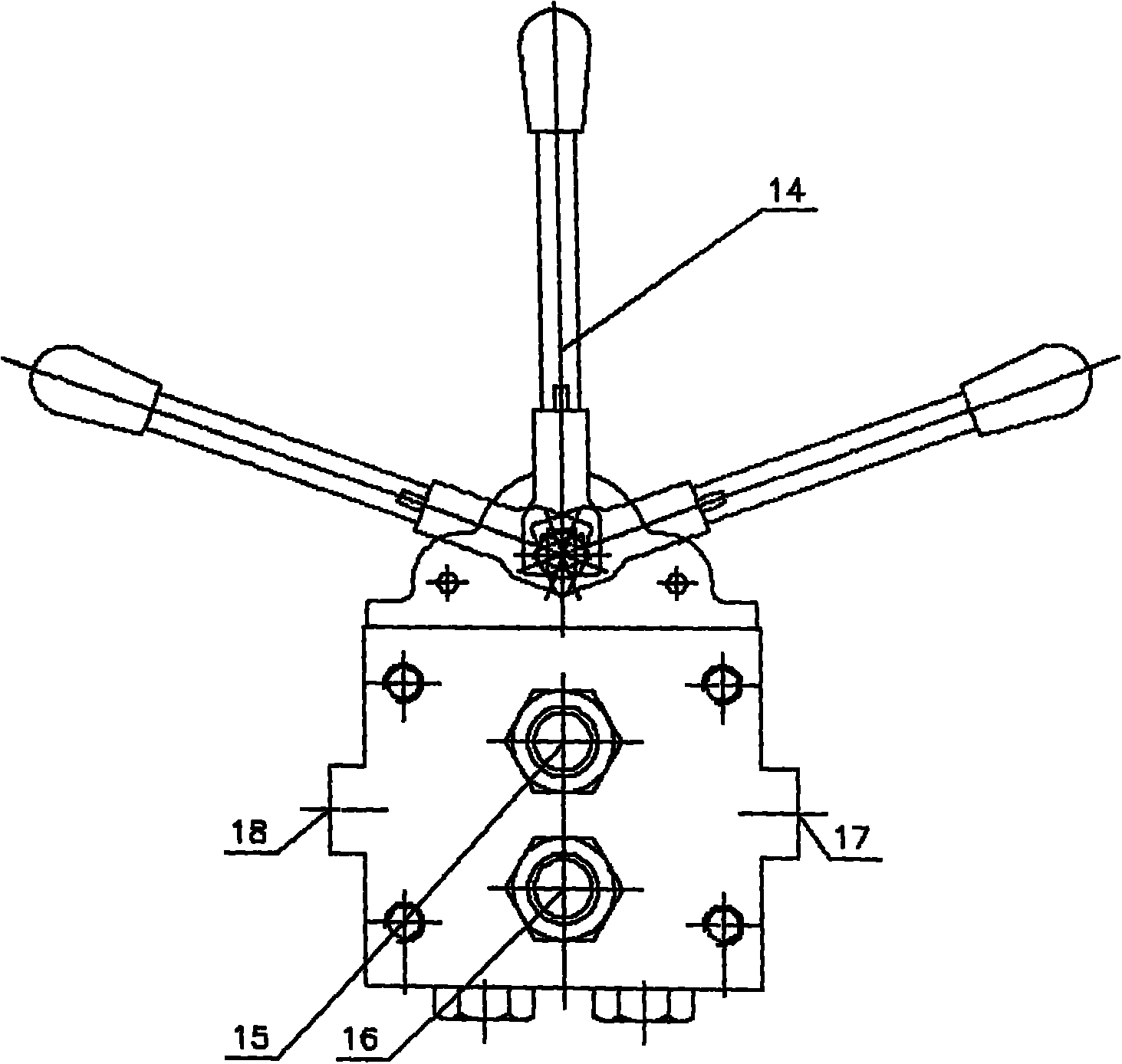

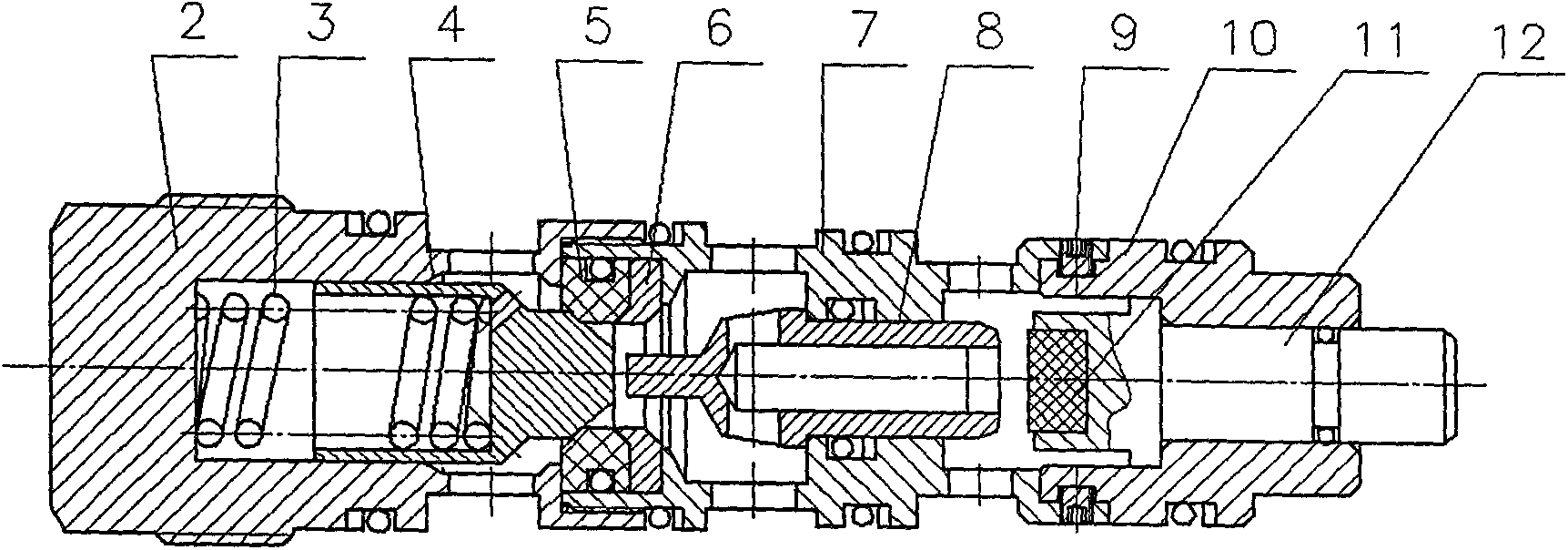

[0011] see Figure 1-Figure 3 , an integral plug-in cone seal reversing valve, which includes a valve body 1, an operating mechanism 14, a front row of working chambers and a rear row of working chambers are opened in the valve body 1, and a liquid inlet hole is drilled on the plane of the valve body 1 The port 16 and the liquid return port 15 communicate with the working chamber, the front working chamber is connected to the working port 17, and the rear working chamber is connected to the working port 2 18; the valve stem 12 is snapped into the liquid return valve pad 11 to form the valve stem assembly, and the valve stem The components are inserted into the rod sleeve 10, the valve column 8 is inserted into the valve sleeve 7, the protective sleeve 6 and the valve seat 5 are clamped in the valve sleeve 7, the valve column 8, the protective sleeve 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com