Tunnel fire-fighting system employing tunnel surging water as water source

A technology for fire protection systems and tunnels, applied in water supply pipeline systems, drinking water installations, and configuration of water supply pools, etc., can solve the problems of water seepage, water leakage, and low feasibility in pools, and achieve convenient water intake, cost reduction, and simple water intake facilities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and examples.

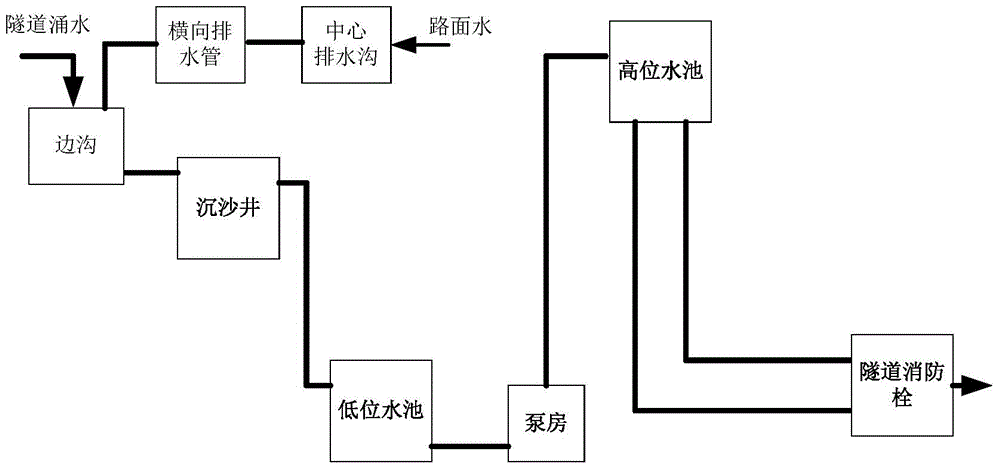

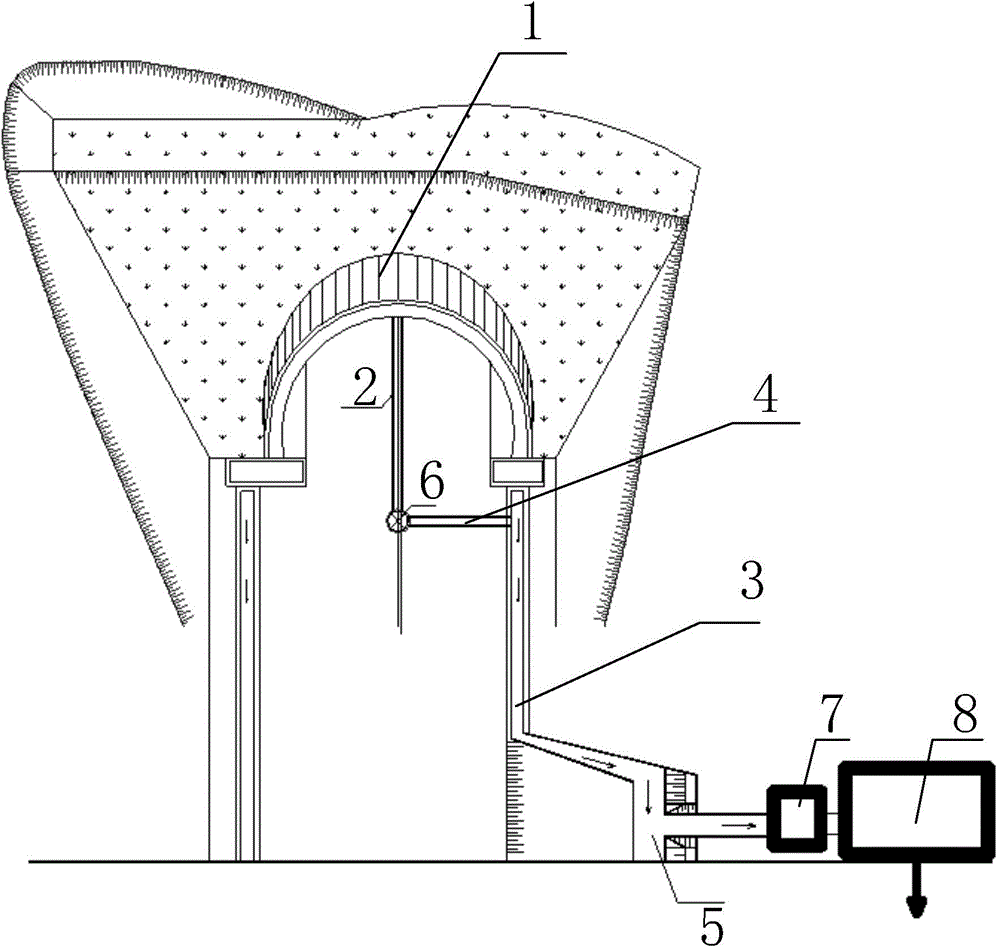

[0017] The seepage pipe collects the tunnel gushing water in the soil and rocks on the roof of the tunnel, and the tunnel gushing water flows down the seepage pipe to the side ditches on both sides of the tunnel entrance; at the same time, when it rains, the accumulated water on the road flows into the side ditches and the central drainage ditch, and the side ditches and the central drainage ditch The water from the side ditch is collected into the side ditch on one side through the horizontal drainage pipe, and the water collected from the side ditch is introduced into the grit chamber through the drainage ditch built on the side of the road. The pipes installed on the upper part of the well wall of the sand sinking well automatically flow to the lower pool, and then the clean water is sent to the high pool through the pump room. Since the position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com