Sealing device for plunger pump and plunger pump

A sealing device and plunger pump technology, which is applied to the components of the pumping device for elastic fluid, pump components, variable displacement pump components, etc. Its proper grasping and other problems can avoid bad deformation and ensure the sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

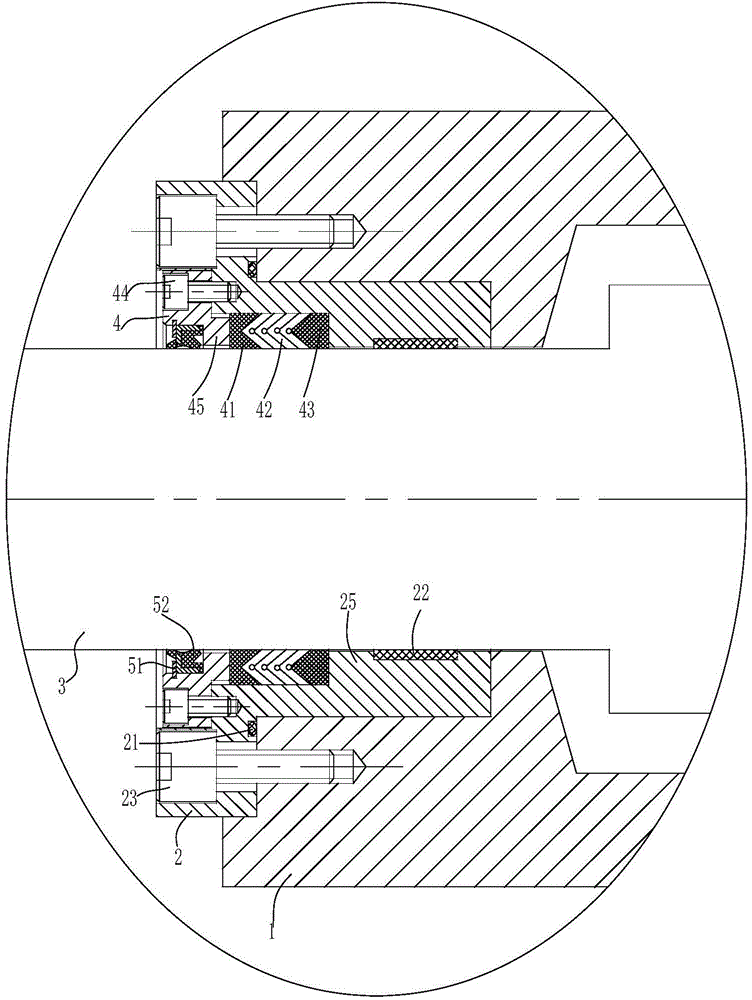

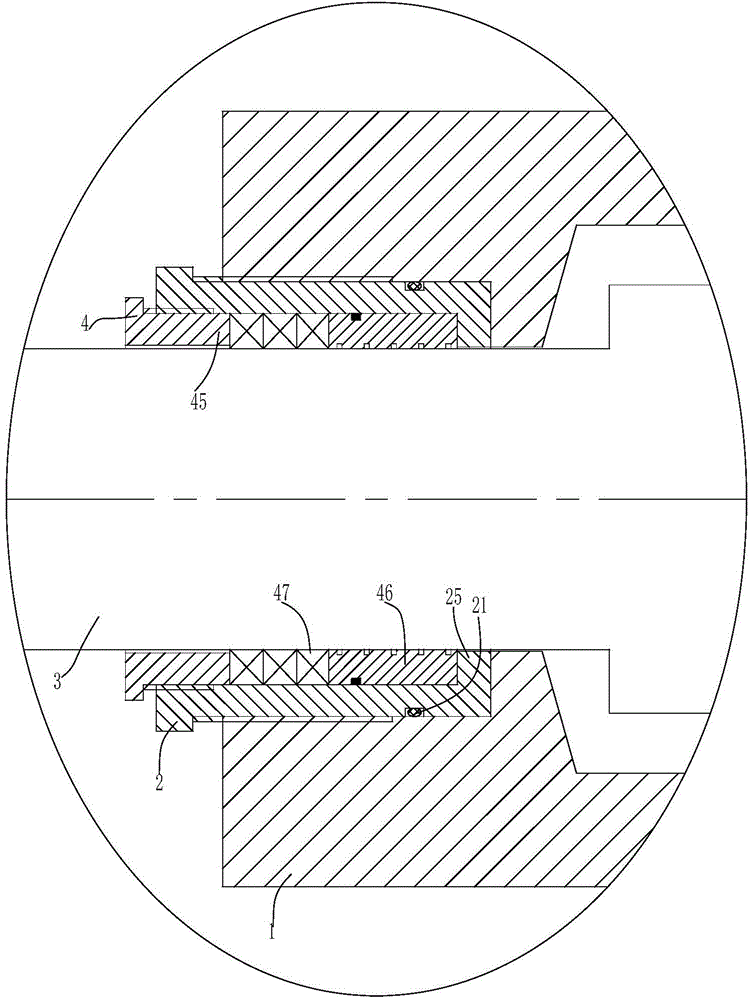

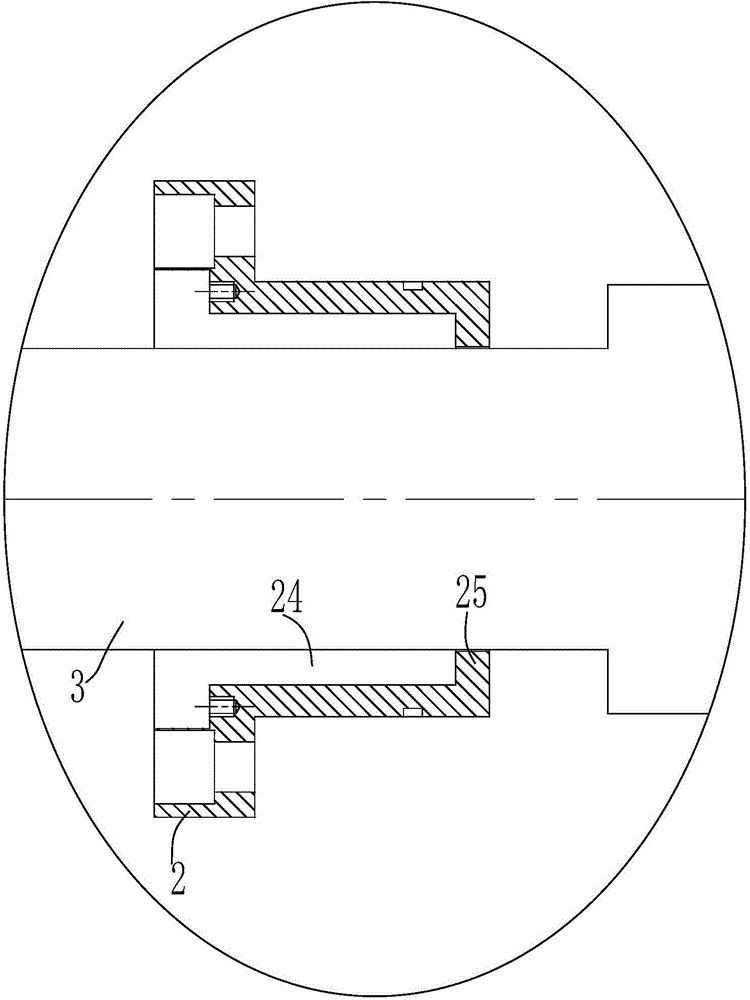

[0028] refer to figure 2 , a sealing device for a plunger pump, including a pump cylinder 1 with a plunger hole and a plunger part 3 with one end extending into the plunger hole, and also includes a stuffing box 2 and a compression cover 4, and the stuffing box 2 is cylindrical , one end of the stuffing box 2 extends into the sealed cavity, and the other end is placed outside the sealed cavity. The sealed cavity is an annular cavity between the plunger part 3 of the plunger pump and the opposite peripheral surface of the plunger hole. The stuffing box 2 One end extending into the sealing chamber has an annular flange 25 protruding radially inward, and the outer peripheral surface of the stuffing box 2 is in clearance fit with the inner peripheral surface of the plunger hole; refer to image 3 The space between the end surface of the annular flange 25 facing the outside of the plunger pump, the inner peripheral surface of the stuffing box 2 and the outer peripheral surface of ...

specific Embodiment 2

[0032] refer to figure 1 , a sealing device for a plunger pump, including a pump cylinder 1 with a plunger hole and a plunger part 3 with one end extending into the plunger hole, and also includes a stuffing box 2 and a compression cover 4, the stuffing box 2 is cylindrical, and the stuffing box One end of the box 2 extends into the sealed cavity, and the other end is placed outside the sealed cavity. The above-mentioned sealed cavity is an annular cavity between the plunger part 3 of the plunger pump and the opposite peripheral surface of the plunger hole. The stuffing box 2 extends into the sealed cavity. One end of the sealing chamber has an annular flange 25 protruding radially inward, and the outer peripheral surface of the stuffing box 2 is in clearance fit with the inner peripheral surface of the plunger hole; refer to image 3 The space between the end surface of the annular flange 25 facing the outside of the plunger pump, the inner peripheral surface of the stuffing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com