A diffuser structure applied to compressor

A compressor and diffuser technology, which is applied in the field of compressor accessories, can solve the problems of surge, flow deterioration of the flow channel, and rotation separation, etc., and achieves the effects of low production cost, improved gas flow, and increased gas flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

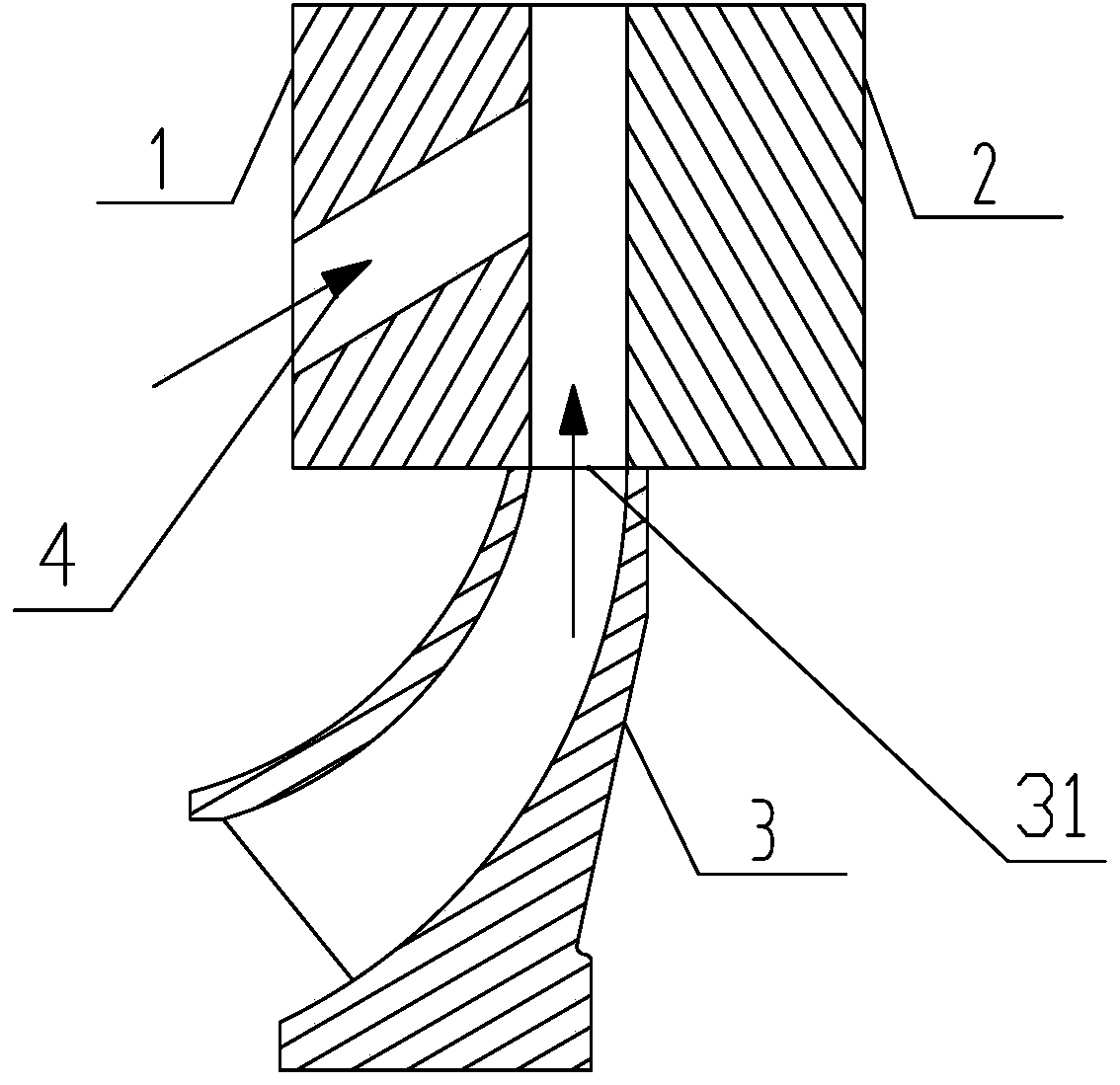

[0043] Such as Figure 4 , Figure 5As shown, it is a specific embodiment of a diffuser structure applied to a compressor proposed in this embodiment. In this embodiment, a high-pressure gas channel 4 is set on the first wall surface 1, and the high-pressure gas channel 4 is a circular channel. Holes, the axis of the circular through-hole high-pressure gas channel 4 and the side wall of the first wall 1 are set at an angle of β, and the value of β is 40°-90°, which is 60° in this embodiment.

[0044] The included angle between the projection of the axis of the high-pressure gas channel 4 on the first wall 1 and the axis line is α, and the included angle α is consistent with the outlet angle of the equipment that delivers high-pressure refrigerant to the high-pressure gas channel 4. In this implementation In the example, the included angle α is an acute angle of 60°.

[0045] The high-pressure gas channel 4 processed according to the above requirements also has the effect of ...

Embodiment 2

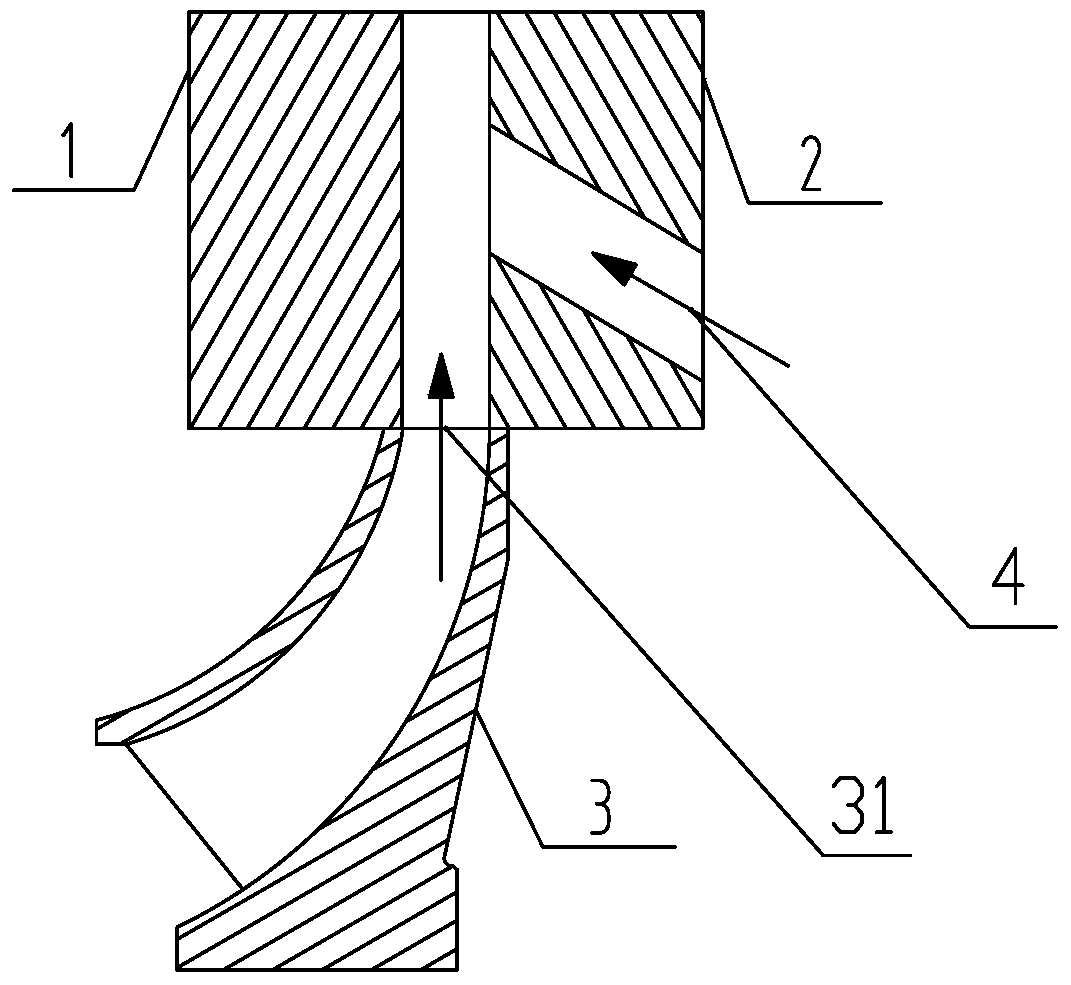

[0049] Such as Image 6 with Figure 7 Shown is a specific implementation of a diffuser structure applied to a compressor proposed in this embodiment.

[0050] The shape of the high-pressure gas channel 4 in this embodiment is a fan-shaped annular through hole, the axial direction of the fan-shaped ring-shaped through hole is perpendicular to the side wall of the first wall 1, and the high-pressure refrigerant enters the gas outlet channel along the direction perpendicular to the first wall 1 among. For the fan-shaped through hole, the high-pressure refrigerant will be distributed around the first wall 1 along the fan-shaped hole, further increasing its range of action.

[0051] The number of high-pressure gas passages 4 in the fan-shaped through-holes in this embodiment is four, which are evenly arranged on the first wall surface 1 along the circumferential direction. Of course, it can also be arranged on the second wall surface 2 , or be arranged on the first wall surface...

Embodiment 3

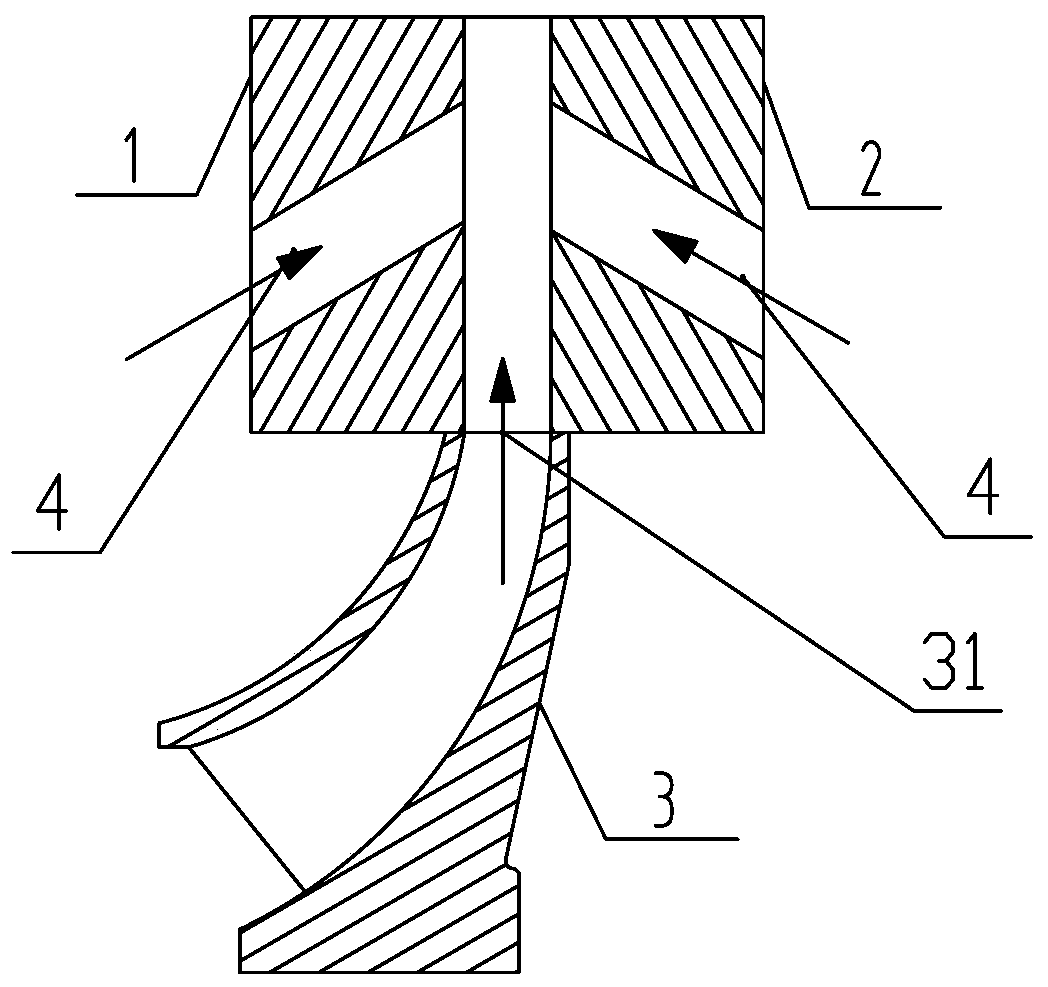

[0053] Such as Figure 8 with Figure 9 Shown is a specific implementation of a diffuser structure applied to a compressor proposed in this embodiment.

[0054] In this embodiment, a high-pressure gas channel 4 with an annular groove structure is provided on the first wall 1 or the second wall 2, and the annular groove structure in this embodiment is adopted so that the high-pressure refrigerant enters the gas outlet channel along a direction perpendicular to the first wall 1 among.

[0055] The high-pressure gas channel 4 of the annular groove structure is conducive to further increasing the range of action of the annular "gas-sealed wall". For the high-pressure gas channel 4 of the annular groove structure, the introduced high-pressure refrigerant will form a continuous and uninterrupted "air-tight wall" zone near the wall surface where the annular groove is set, and its effect is compared with that of the first and second embodiments. The structural effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com