Hydraulic shock absorber with active adjustable damping

A hydraulic shock absorber and active technology, applied in the field of hydraulic shock absorbers, can solve the problems of high manufacturing cost, unstable performance, non-adjustable damping, etc., and achieve the effects of low requirements, reliable performance and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

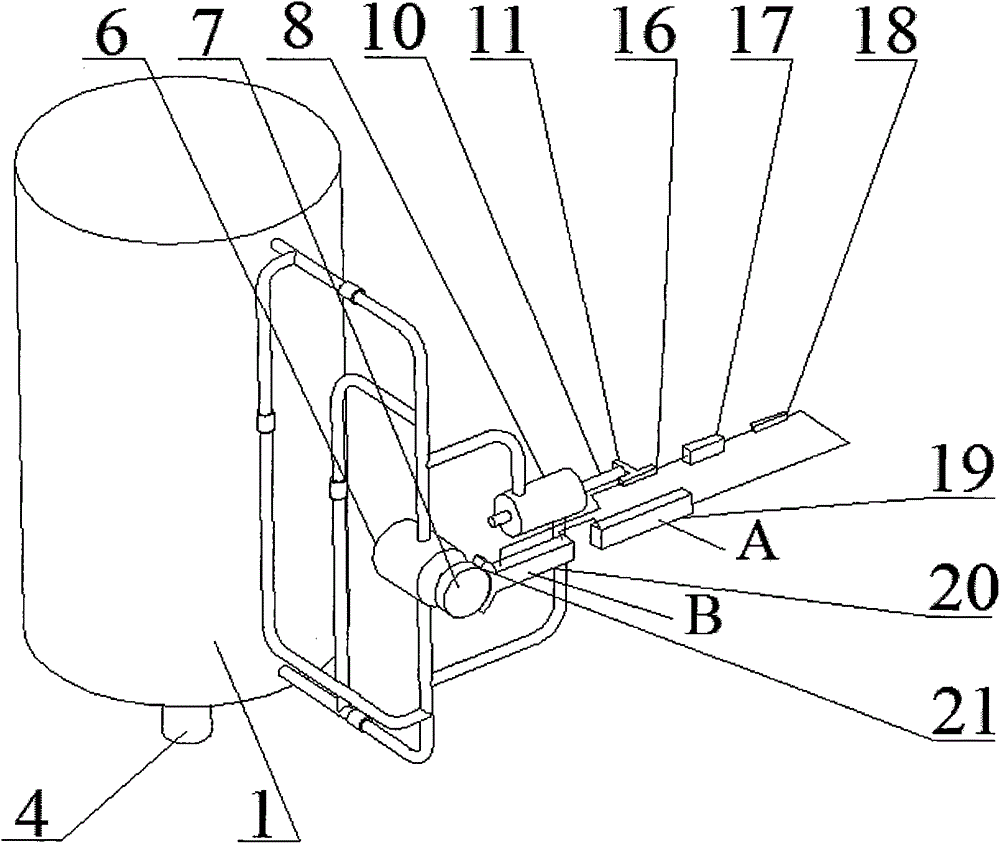

[0021] figure 1 is a top view of a shock absorber with actively adjustable damping.

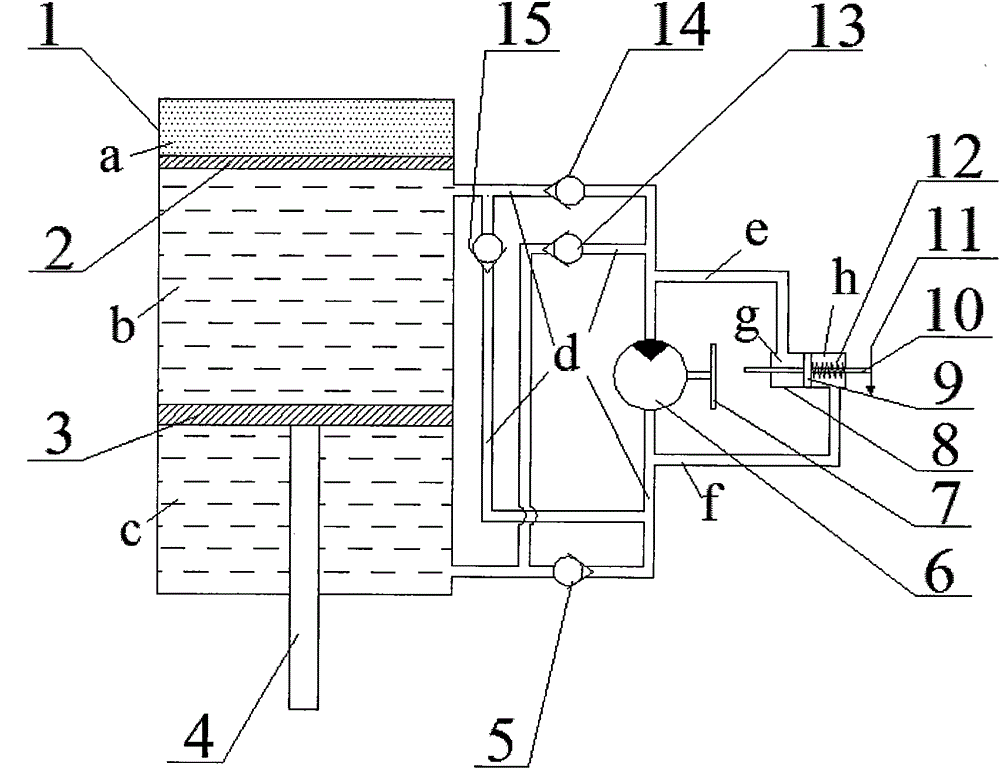

[0022] Such as figure 2 As shown, the shock absorber includes a cylinder 1, a floating piston 2, a piston 3 and a piston rod 4. Oil cylinder 1 is divided into compressed air chamber a, upper oil chamber b and lower oil chamber c by floating piston 2 and piston 3 . The diameter of the floating piston 2 is the same as that of the oil cylinder 1, and can freely slide along the axial direction of the oil cylinder 1, forming a closed cavity with one end of the oil cylinder 1, and the airtight cavity is filled with high-pressure air to ensure that the oil in the oil cylinder 1 does not come into contact with the air . Both the floating piston 2 and the piston 3 are in sealing contact with the inner wall of the oil cylinder 1 . The piston rod 4 is connected with the piston 3 and protrudes from the lower end of the oil cylinder 1 . The compressed air chamber a can effectively reduce the high-fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com