Top-mounted type ball valve on-line maintenance assembling and disassembling device

A ball valve, assembled technology, applied in the field of maintenance and disassembly devices for ball valves, achieves the effects of convenient online maintenance, convenient assembly and disassembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

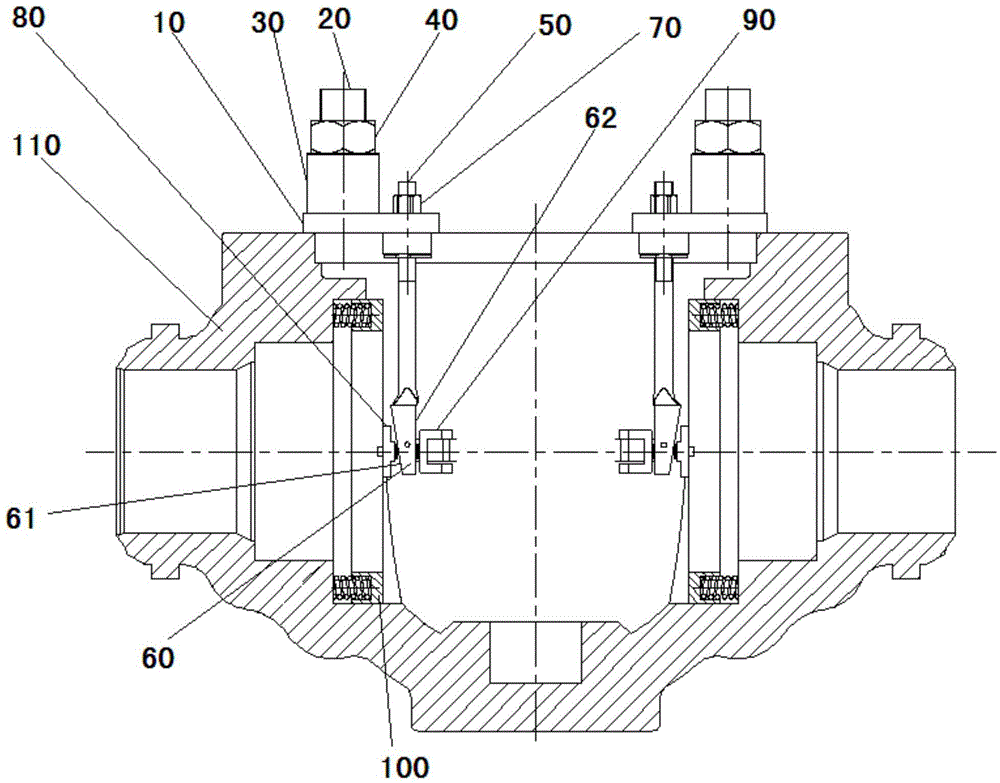

[0028] see figure 1 As shown, the present invention discloses an online maintenance and disassembly device for a top-loading ball valve. The maintenance and disassembly device includes two maintenance and disassembly device bodies with the same structure and bilateral symmetry arranged in the adjusted valve body 110 .

[0029] This each maintenance dismounting device body all comprises a limit plate 10, one is used to fix the limit plate 10 on the stud stud 20 on the flange in the assembled valve body, one is arranged on the limit plate 10 top Adjusting pad 30, a hex nut 40 arranged on the top of the adjusting pad 30, an inclined adjusting rod 50, an adjusting nut 70 for fixing and adjusting the upper and lower positions of the inclined adjustin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com