Comprehensive remote monitoring system for hydraulic oil station

A comprehensive monitoring system and hydraulic oil technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of low efficiency, difficulty in meeting daily production and life, and high maintenance costs, and achieve simple structure, Strong practicability and the effect of preventing the solenoid valve from overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

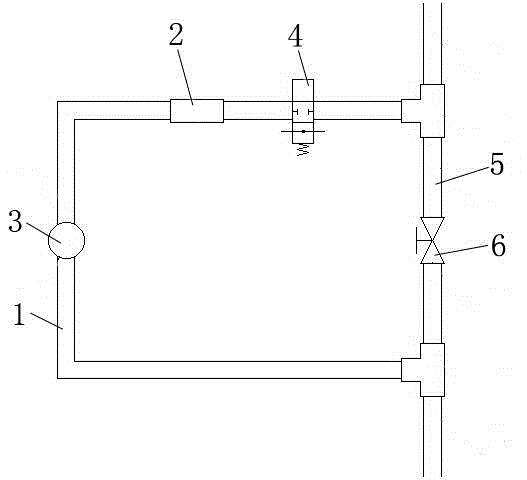

[0013] like figure 1 As shown, the remote integrated monitoring system of the hydraulic oil station includes: an oil supply pipeline 1, the oil supply pipeline 1 is used to connect the hydraulic oil tank and the oil station, the solenoid valve 2 is installed on the oil supply pipeline 1, and the The inlet of the solenoid valve 2 is provided with a booster pump 3, and the outlet of the solenoid valve 2 is provided with a flow rate detection switch 4, and the solenoid valve 2, booster pump 3 and flow rate detection switch 4 are all connected to the main control system. When in use, the oil supply controller is used to control the opening and closing of the electromagnetic valve 2 and the booster pump 3, and the oil tank is controlled to supply oil to the oil station, so the control is convenient and the working efficiency is high.

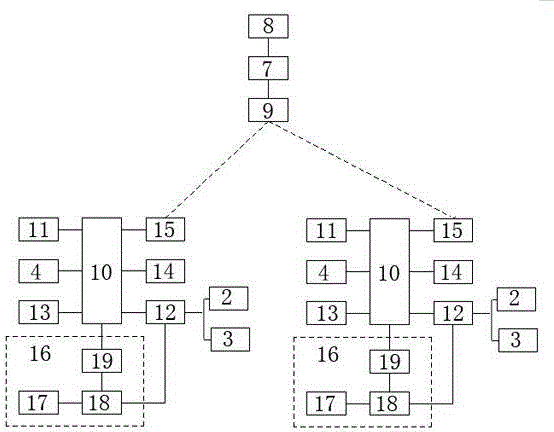

[0014] like figure 2 As shown, the main control system includes a remote management system and a plurality of on-site management systems connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com