Rotary encoder based on light sensation principle and measuring method thereof

A rotary encoder and principle technology, applied in the field of encoders, can solve the problems of complex code disc manufacturing process, inability to meet ultra-high resolution processing and production, etc., and achieve the effect of high physical resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

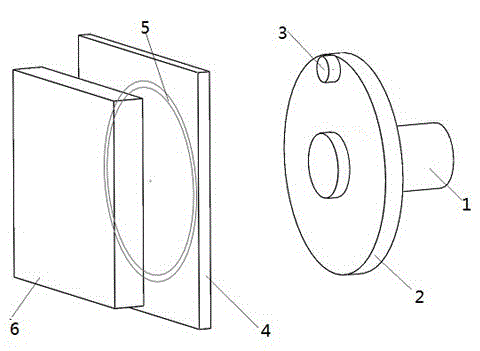

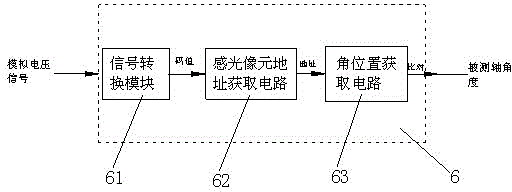

[0029] like figure 1 As shown, it is a schematic structural diagram of a rotary encoder based on the light-sensing principle in this embodiment, including a main shaft 1, which is connected to the measured shaft through a coupling, and a circular wheel 2 is fixed on the main shaft 1, and the laser The emitting device 3 is installed on the circular wheel 2, and the photosensitive resistance surface 4 is located in front of the laser emitting device 3, so that when the main shaft 1 rotates, the laser emitted by the laser emitting device 3 can be formed on the photosensitive resistance surface array. A circular spot track 5, the photosensitive element receiving the spot on the photosensitive photoresistor surface 4 converts the laser signal into an analog voltage signal and transmits it to the signal processing system 6, such as figure 2 As shown, the signal processing system 6 includes a signal conversion module 61, a photosensitive pixel address acquisition circuit 62 and an a...

Embodiment 2

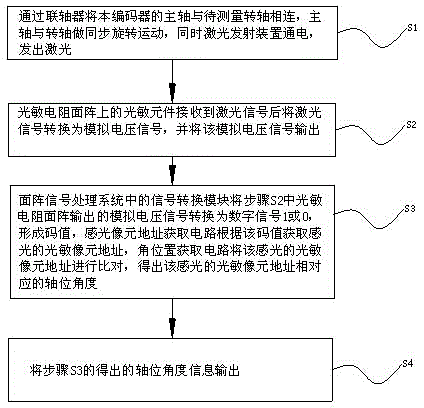

[0031] This embodiment is the measurement method of the rotary encoder based on the light-sensing principle of the present invention, such as image 3 As shown, it specifically includes the following steps:

[0032] S1. Connect the main shaft of the encoder to the rotating shaft to be measured through a coupling, the main shaft and the rotating shaft perform synchronous rotation, and at the same time the laser emitting device is powered on to emit laser light;

[0033] S2. After receiving the laser signal, the photosensitive element on the photoresistor array converts the laser signal into an analog voltage signal, and outputs the analog voltage signal;

[0034] S3. The signal conversion module in the signal processing system converts the analog voltage signal output by the photosensitive resistor area array in step S2 into a digital signal 1 or 0 to form a code value, and the photosensitive pixel address acquisition circuit obtains the photosensitive photosensitive image ac...

Embodiment 3

[0042] In this embodiment, the rotary encoder in Embodiment 1 and the measurement method in Embodiment 1 will be combined;

[0043] For the convenience of illustration, in this embodiment, the photoresistive element irradiated by laser light on the photoresistor array is composed of 4 cmos photosensitive elements (in fact, there are multiple photosensitive elements), and the analog voltage signal output by the photosensitive element irradiated by laser is passed through The signal conversion mode in the signal processing system is converted into a digital signal 1 or 0, specifically: when the first cmos photosensitive element receives the laser signal, and the remaining 3 cmos photosensitive elements do not receive the laser signal, the photosensitive resistance element outputs The analog voltage signal is converted into a specific code value 0001 by the signal conversion module in the signal processing system, and the photosensitive pixel address acquisition circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com