An axial continuous temperature and pressure measurement device for fluid in a pipe

A pressure measuring device and internal fluid technology, applied to measuring devices, instruments, etc., can solve problems such as long dynamic response time, complex structure of measuring devices, and affecting the working state of fluids, and achieve low operation and maintenance costs, reliable measurement technology, and measurement The effect of structural simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation.

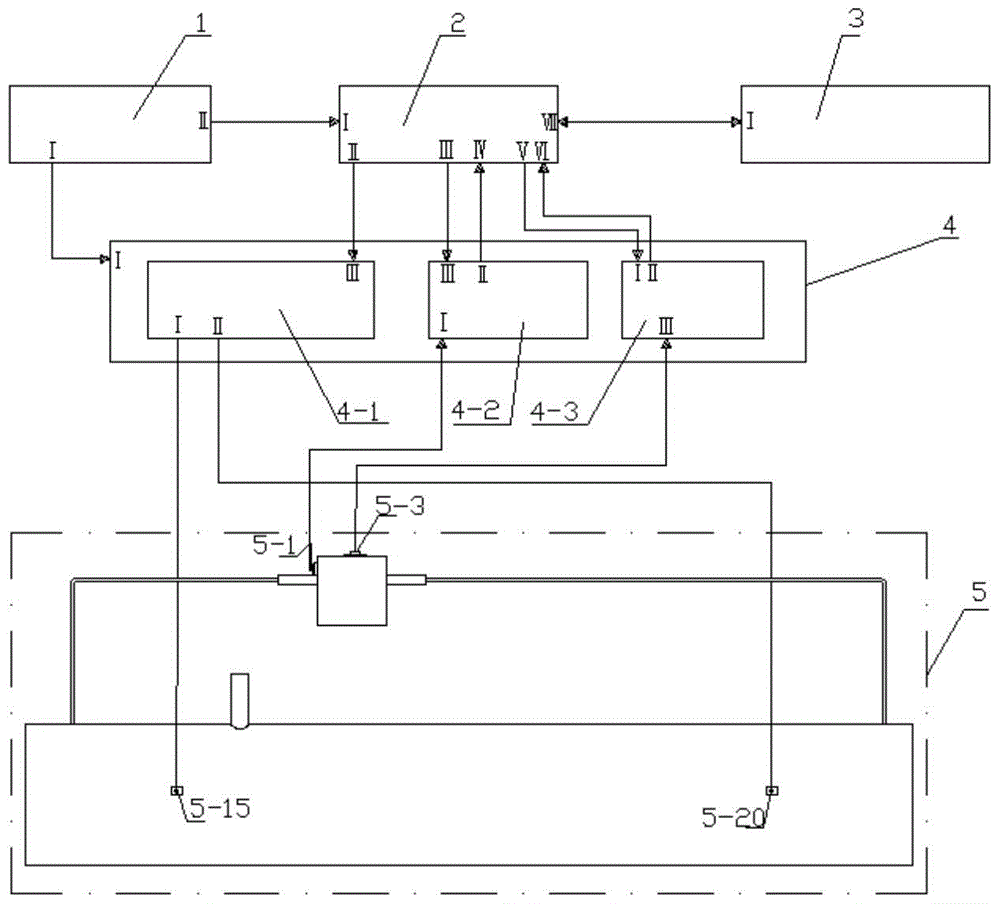

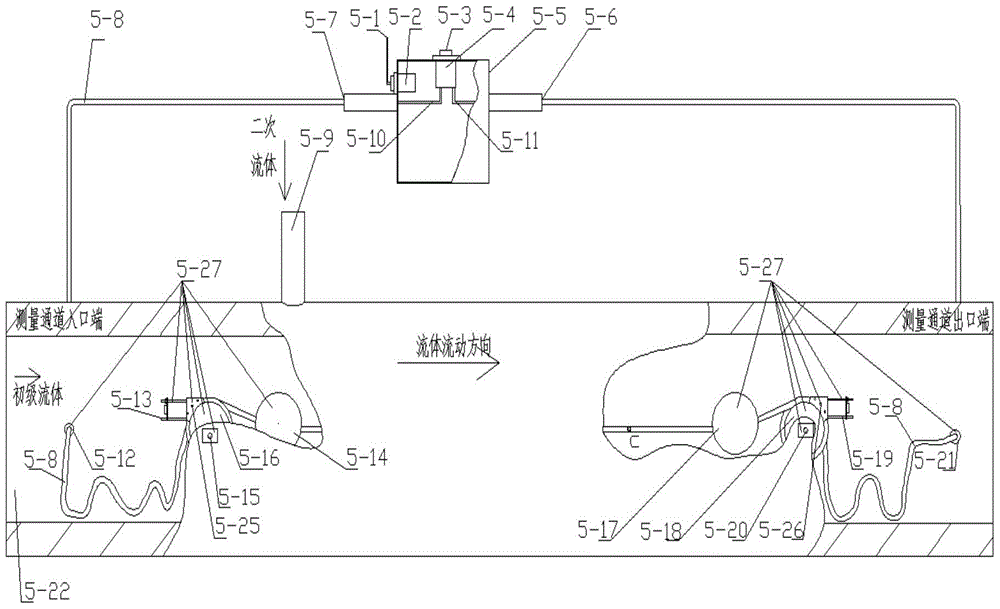

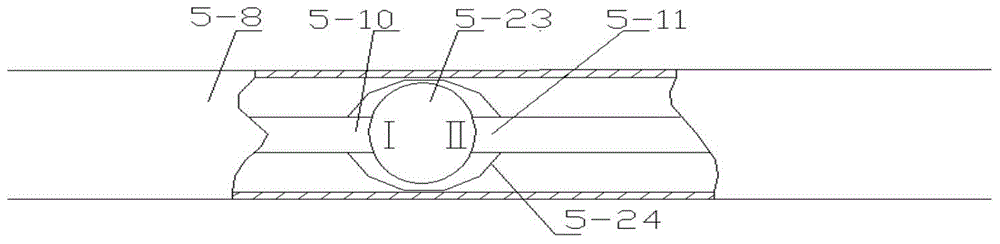

[0037] The structure of an axial continuous temperature and pressure measurement device for fluid in a pipe is as follows: figure 1 As shown, it consists of power supply 1, micro control unit 2, upper computer 3, drive acquisition module 4 and measurement section 5:

[0038] 1. The structure of each part:

[0039] 1) The power supply 1 is provided with interface I and interface II.

[0040] 2) The micro-control unit 2 is equipped with a power supply interface I, a drive module control interface II, a pressure measurement command transmission interface III, a pressure data reception interface IV, a temperature measurement command transmission interface V, a temperature data reception interface VI, and a host computer signal transmission interface , Receiving interface VII.

[0041] 3) The upper computer 3 is provided with an upper computer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com