A heat exchange medium and cooling device installed with the heat exchange medium

A technology of heat exchange medium and cooling device, applied in maintenance and safety accessories, metal processing machinery parts, metal processing equipment, etc., can solve the problems of cooling effect of coolant leakage, high sealing requirements of heat exchange medium, pollution of working environment, etc. Achieve the effect of overcoming coolant leakage, reducing energy consumption and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with each accompanying drawing, the present invention is described in detail.

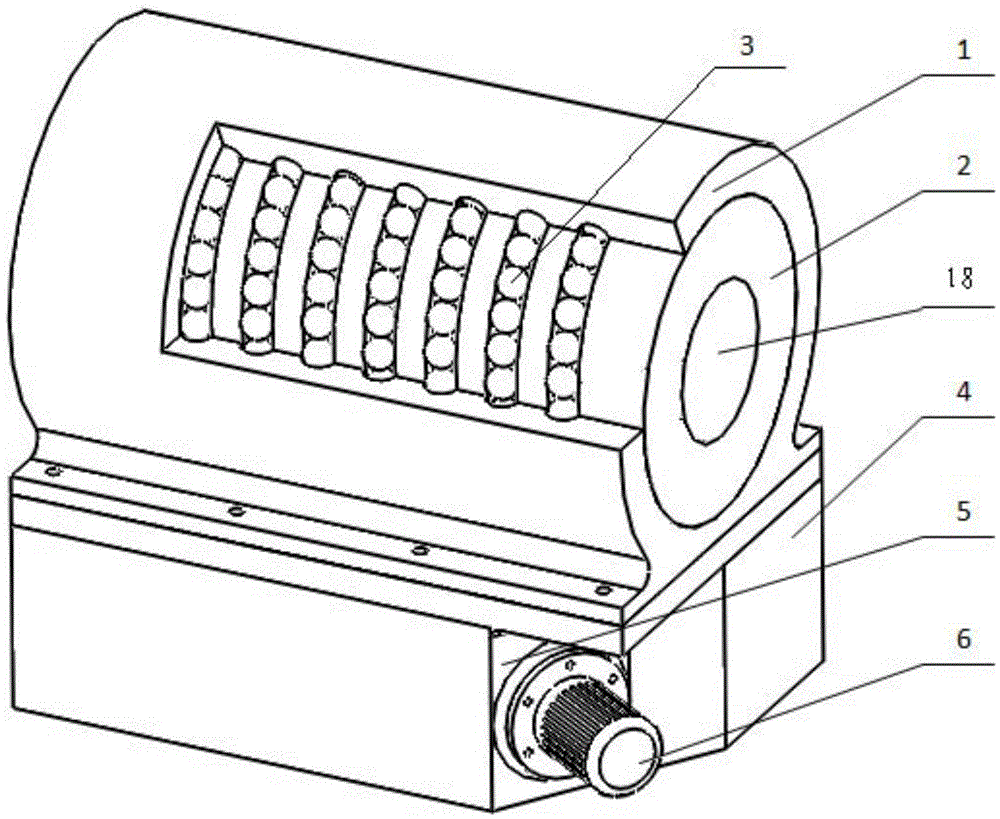

[0039] Such as Figure 1~6 As shown, a cooling device, comprising:

[0040] The heat exchange medium 3 includes a hollow sphere 16, and a phase change material 17 filled in the hollow sphere, see Figure 6 , which can prevent the phase change material from leaking out of the hollow sphere, and there is no leakage problem;

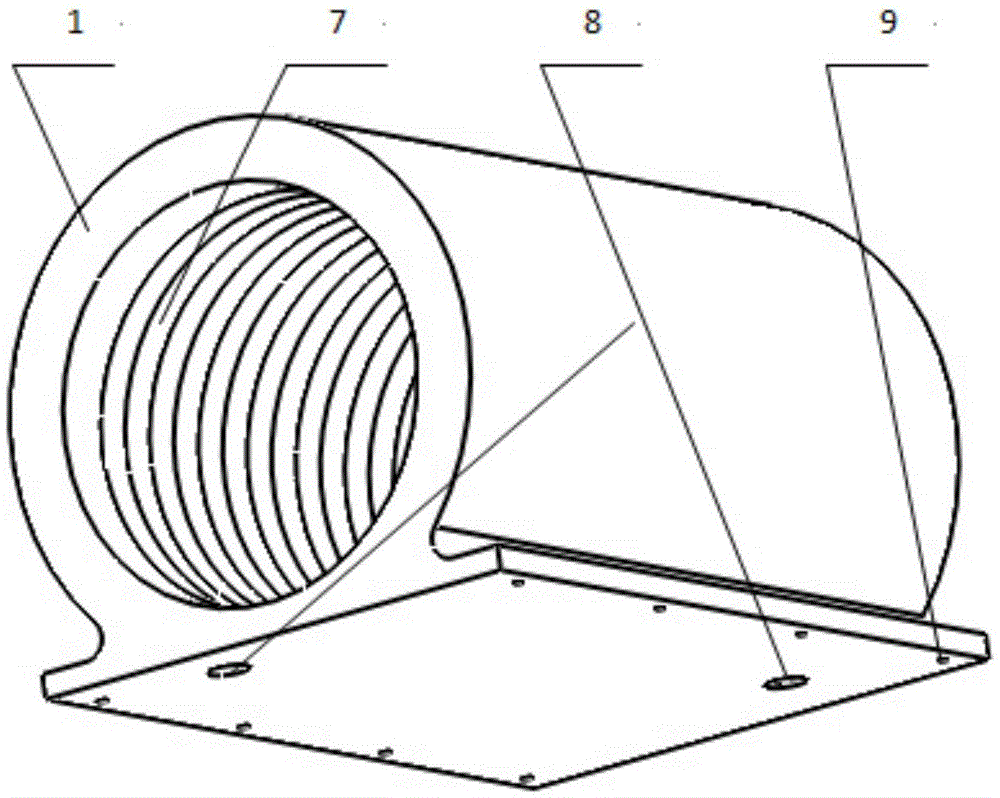

[0041] Outer cooling jacket 1, the inner wall is provided with a first thread groove 7, and the outer wall of the outer cooling jacket has a fixed plane, and a number of countersunk holes 9 are arranged on the fixed plane;

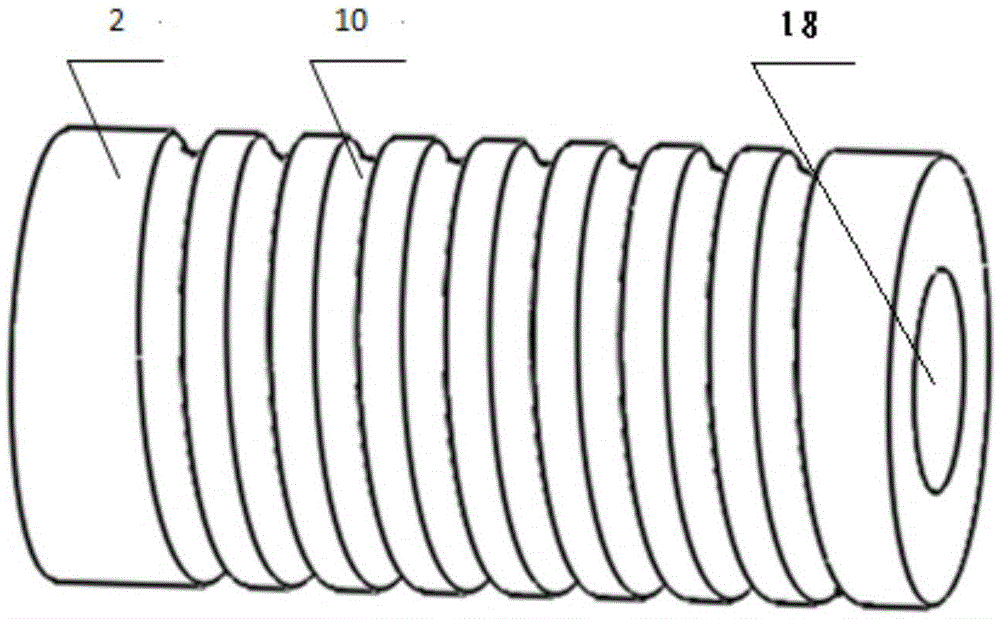

[0042] The inner cooling jacket 2 is coaxially arranged inside the outer cooling jacket 1, and the outer wall of the inner cooling jacket is provided with a second threaded groove 10 matched with the first threaded groove 7, and the first threaded groove and the second threaded groove form a heat exchange The spiral heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com