Asynchronous high-speed countercurrent chromatography instrument with multiple separation columns

A high-speed countercurrent chromatography and separation column technology, applied in material separation, instruments, scientific instruments, etc., can solve the problems of poor sample separation effect, technological innovation, low separation efficiency, etc., to improve the effect and scope of use, and ensure beta value, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

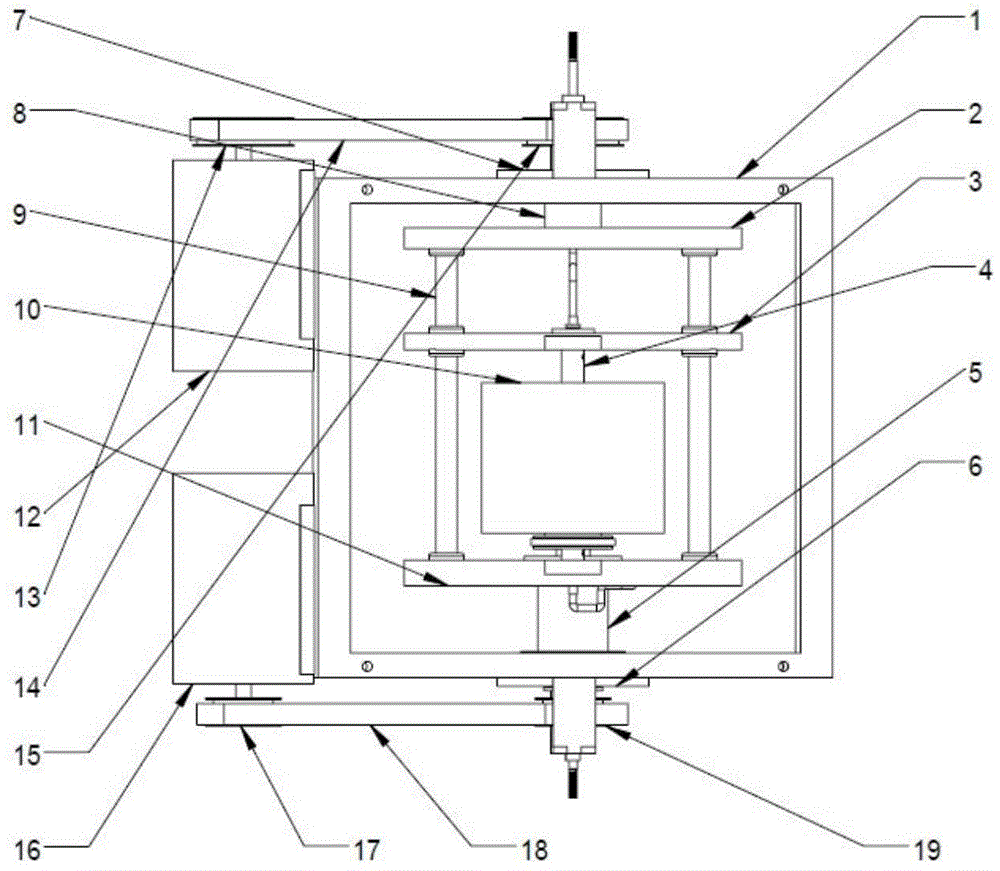

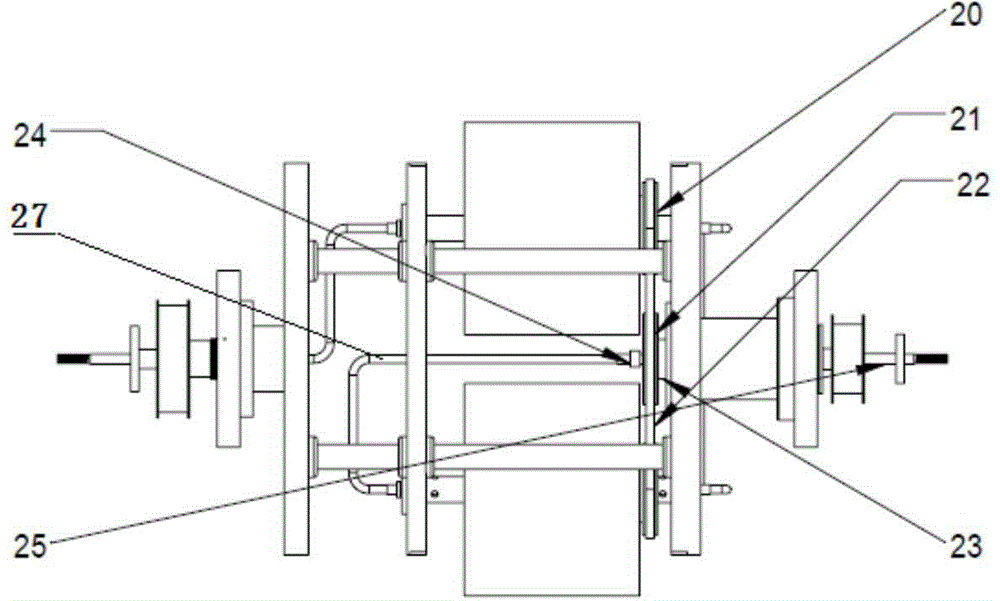

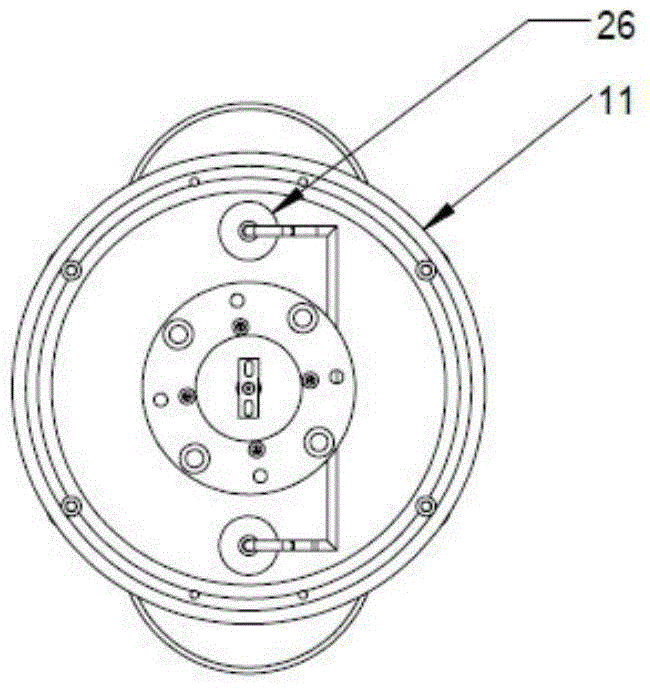

[0027] The following is a detailed structure description based on the above description of an asynchronous multi-column high-speed countercurrent chromatograph. An asynchronous multi-separation column high-speed countercurrent chromatograph consists of a chassis 1, an upper flange 2, a middle flange 3, a separation column shaft 4, a lower rotating shaft 5, a lower rotating shaft bearing end cover 6, and an upper rotating shaft bearing end Cover 7, upper rotating shaft 8, flange connecting rod 9, separation column 10, lower flange 11, revolution motor 12, revolution driving synchronous gear 13, revolution synchronous belt 14, revolution driven synchronous gear 15, self-rotation motor 16 , rotation active synchronous gear 17, autorotation synchronous belt 18, autorotation driven synchronous gear 19, separation column synchronous gear 20, autorotation transmission synchronous gear 21, autorotation transmission belt 22, autorotation transmission shaft 23, rotary sealing joint 24, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com