Winding speed detection device and method

A rotational speed detection and hoisting technology, which is used in measurement devices, linear/angular velocity measurement, velocity/acceleration/impact measurement, etc., can solve the problems of not being widely used, high processing technology requirements, and high manufacturing costs, achieving structural Simple, easy detection process, independent device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

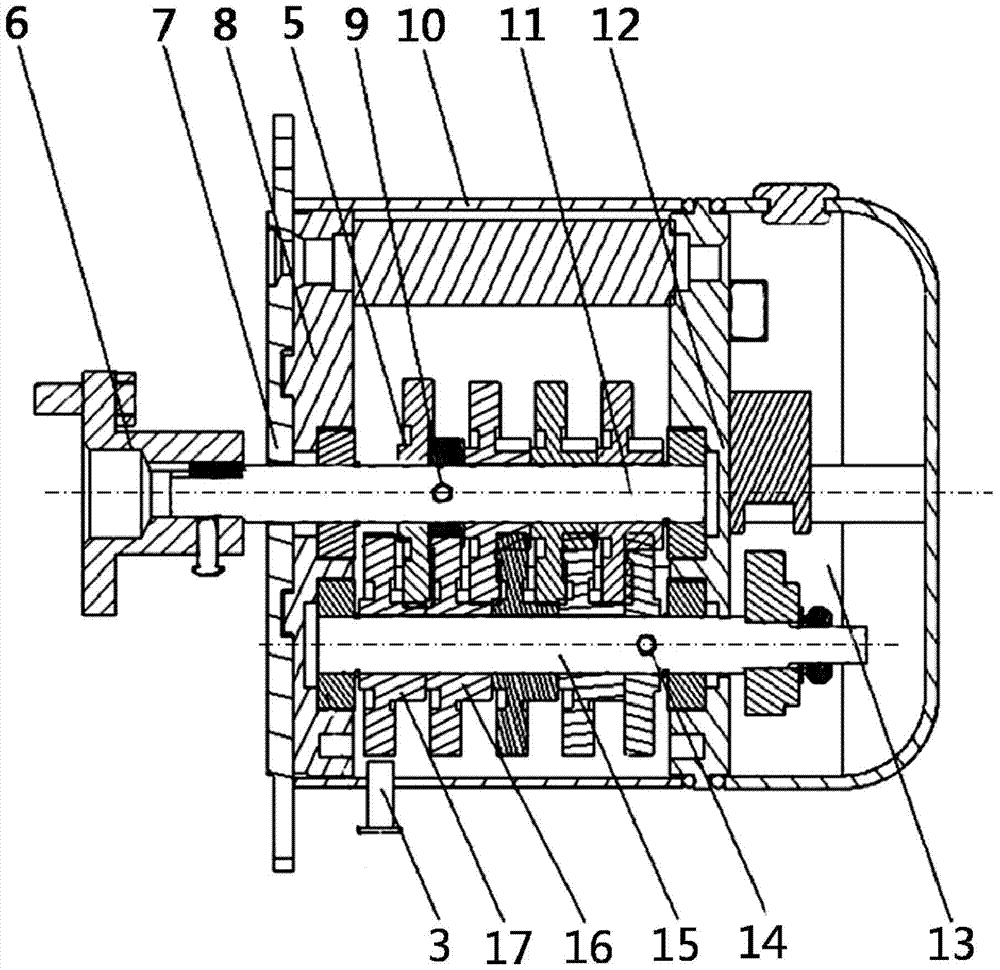

[0032] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0033] In view of the high manufacturing process requirements of the hoist speed detection method in the prior art, and the high cost in all aspects, so that it cannot be widely used, the hoist speed detection device of the present invention makes a breakthrough by adding a gear plate to the output shaft inside the motor In the way of speed detection, a hoist speed detection device with low detection difficulty and low cost is proposed, which will be described in detail below.

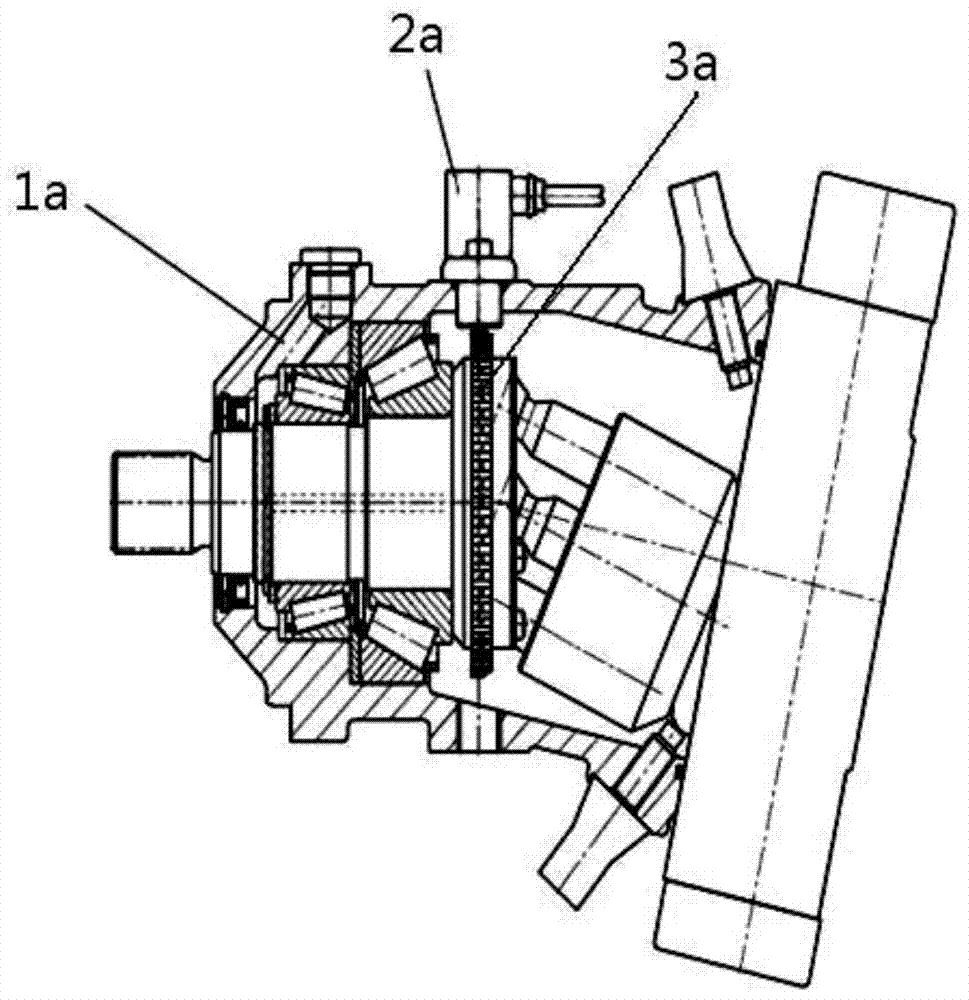

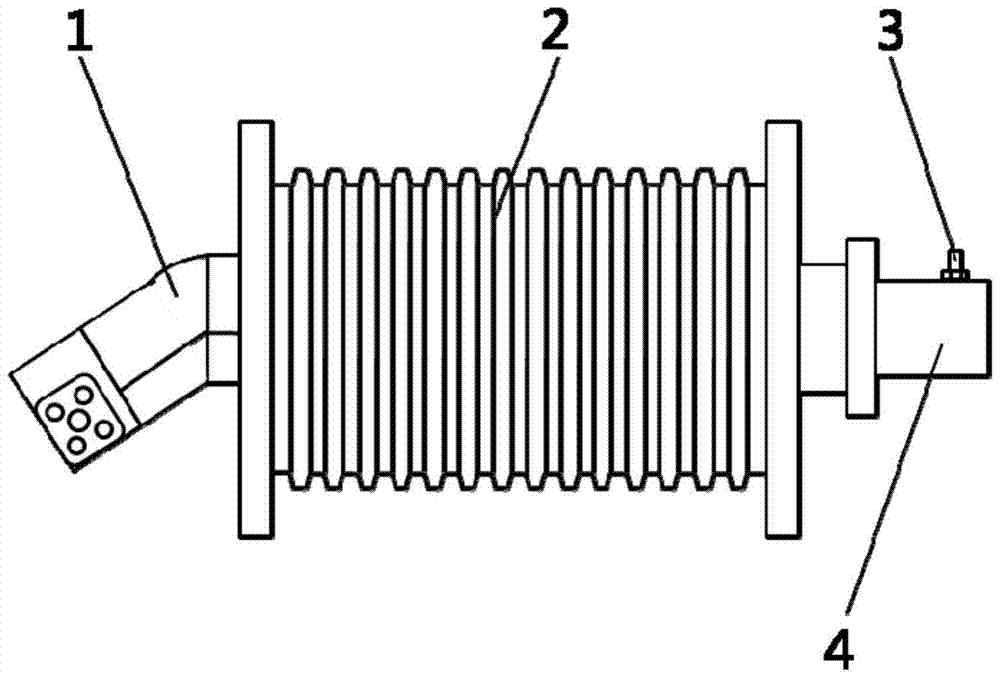

[0034] In one embodiment of the present invention, as figure 2 with image 3 As shown, the hoisting speed detection device includes: a speed reducer and a speed detection sensor 3, the speed reducer is arranged on one side of the hoisting drum 2, the input end of the speed reducer is coaxially arranged with the hoisting drum 2, and the hoisti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com