Integrated device for ptc heater withstand voltage test and cooling strip bonding

A heat dissipation strip and withstand voltage technology, applied in the direction of testing dielectric strength, connecting components, mechanical equipment, etc., can solve the problems of waste of labor resources, high labor intensity of workers, poor safety, etc., to meet the detection speed requirements and reduce manpower input , the effect of reliable combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

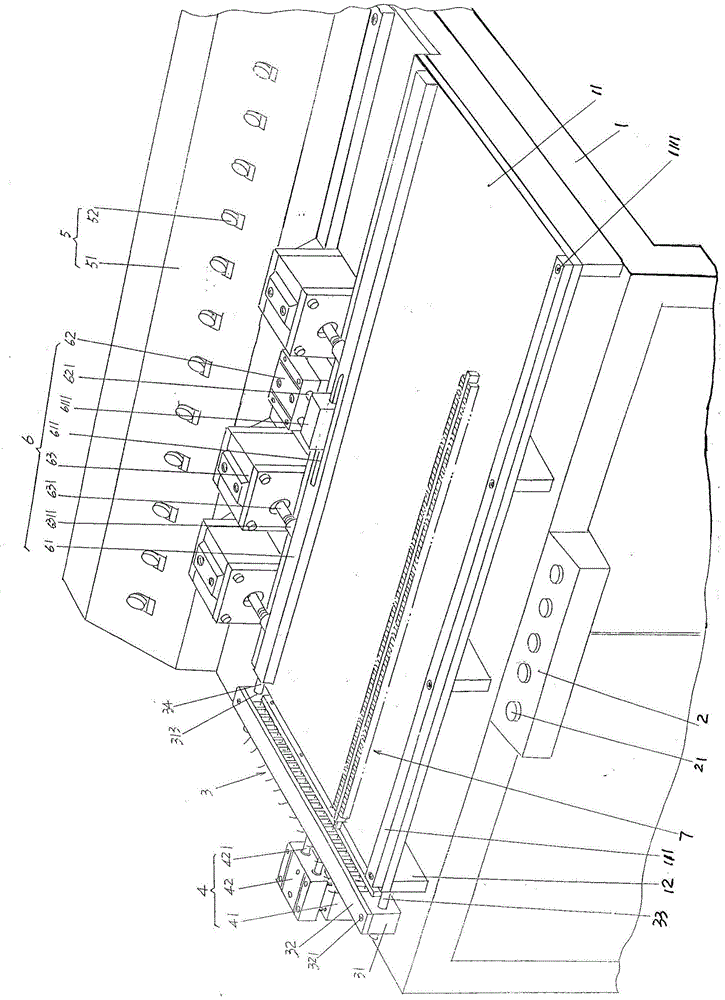

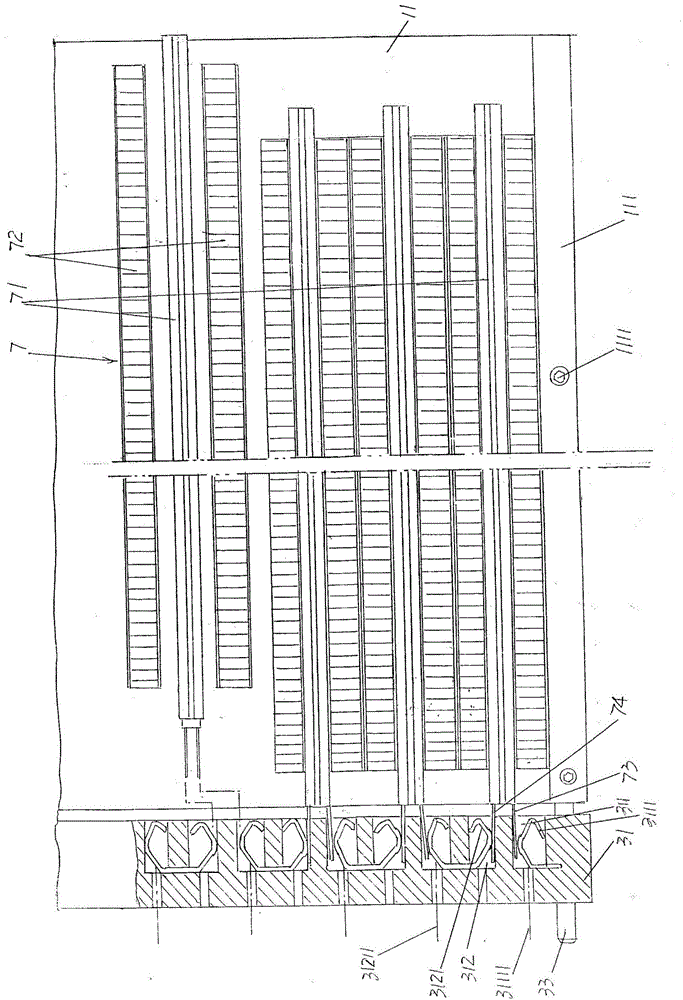

[0027] See figure 1 ,exist figure 1 1 shows a test bench 1, the test bench 1 is set on the floor of the test site in the use state, and a panel 11 is fixed on the upper part of the test bench 1 in the state of vacating above the test bench. On the top of the table panel 11 and at the front edge of the length direction of the table panel 11, a stop bar 111 is fixed with a bar screw 1111; an electrical control box 2 is shown, and the electrical control box 2 is arranged on the length of the test bench 1 The front side of the direction; shows an electrode guide socket 3, the electrode guide socket 3 is mobilely arranged on the test bench 1 at a position corresponding to the left end of the table panel 11, and is electrically controlled with the electric control box 2 Connection; shows an electrode lead socket drive mechanism 4 connected with the electric control box 2 for driving the electrode lead socket 3 to move, the electrode lead socket drive mechanism 4 is in the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com