Electrochromic automobile rear-view mirror body structure and production method thereof

An automotive rear-view mirror and electrochromic technology, which is applied in vehicle parts, optics, instruments, etc., can solve the problems of high cost of mirror body 9, failure of mirror surface of mirror body 9, and high material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

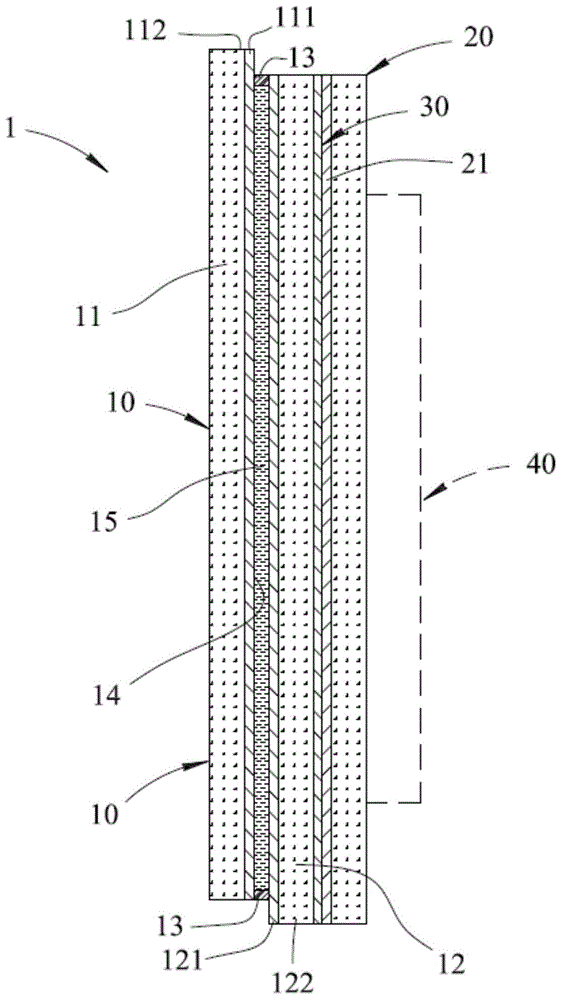

[0025] The above and other technical features and advantages of the present invention will be described in more detail below with reference to the accompanying drawings and embodiments.

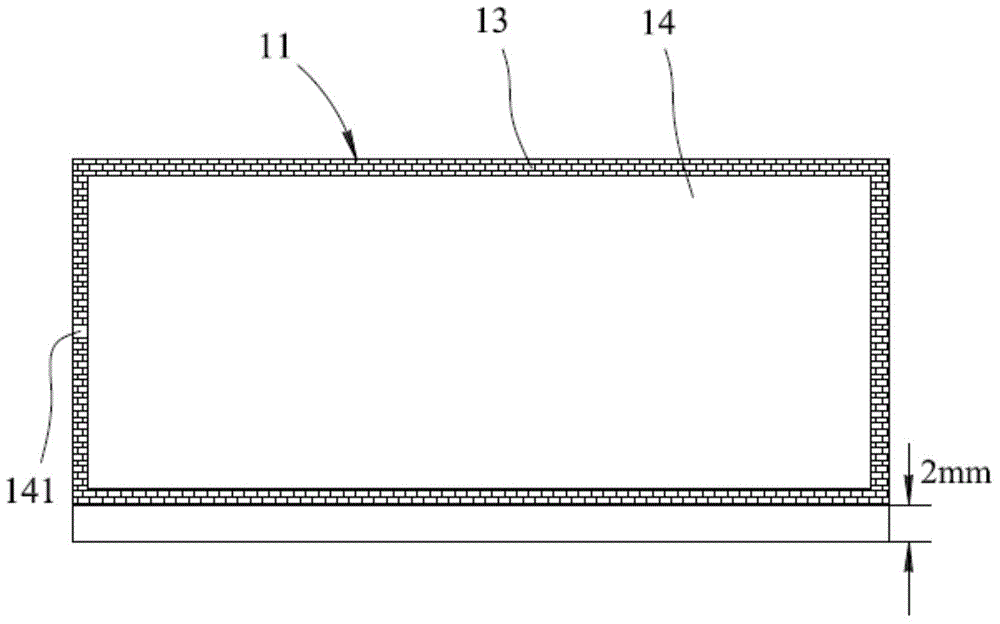

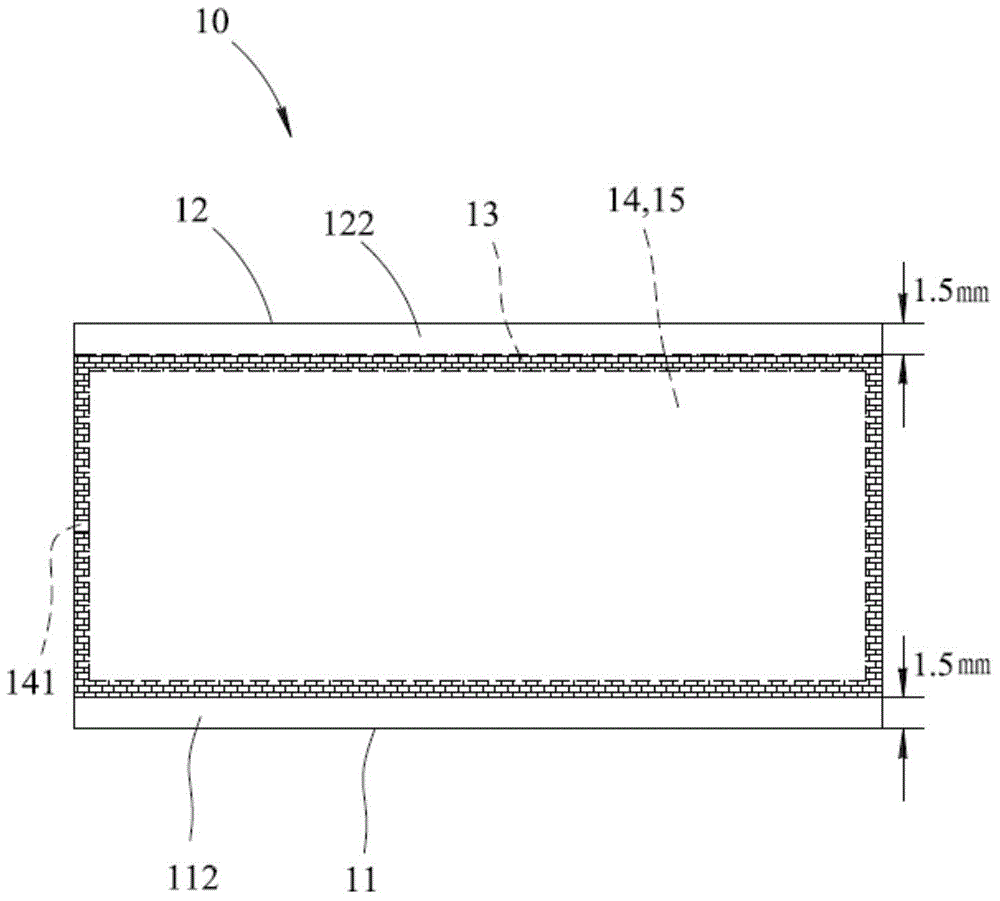

[0026] see Figure 1 to Figure 5 As shown, the present invention is an electrochromic automobile rearview mirror body structure 1 and a manufacturing method thereof. First, two pieces of glass with an area of 10cm x 6cm and a thickness of 1.6mm and a light transmittance of more than 75% are taken, and on the inner surface thereof The transparent conductive layers 111 and 121 with a resistance of 15 ohms are respectively used as the first substrate 11 and the second substrate 12 of the present invention, and then 100 g of epoxy resin is mixed into at least 1% of glass balls with a diameter of 120 μm for further formation Adhesive13. In addition, the long side of the first base material 11 faces upward, and then the adhesive 13 is coated around the first base material 11 by a dispenser. Whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com