Vortex state magnetic storage unit of nano unit structure

A technology of magnetic storage unit and unit structure, applied in the field of magnetic materials and magnetic storage, to achieve the effect of fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

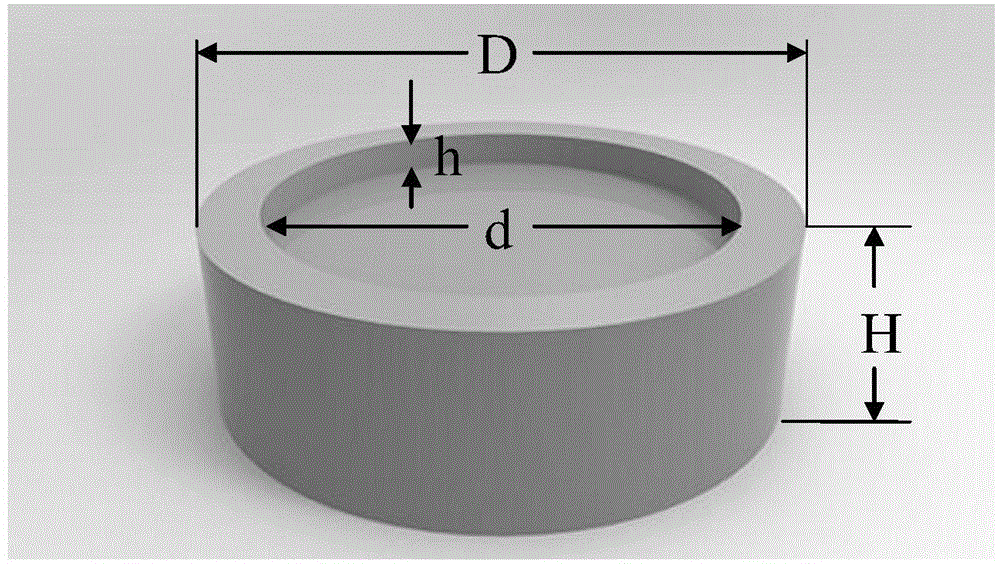

[0016] The present invention adopts currently internationally recognized micromagnetic simulation software (published by NIST of the United States National Institute of Standards) to simulate the magnetic moment distribution of the magnetic unit. In the unit structure of the simulated design (such as figure 1 As shown), a stable vortex magnetic moment distribution is obtained.

[0017] What the unit structure of the present invention used material adopted is the NiFe soft magnetic material commonly used in the storage unit, and its saturation magnetization is M s =8.6×10 5 A / m, the exchange integral is A=1.3×10 -11 J / m. The overall thickness of the groove unit structure is 20nm, the groove depth is 4nm, the outer diameter is 80nm, and the inner diameter is 60nm.

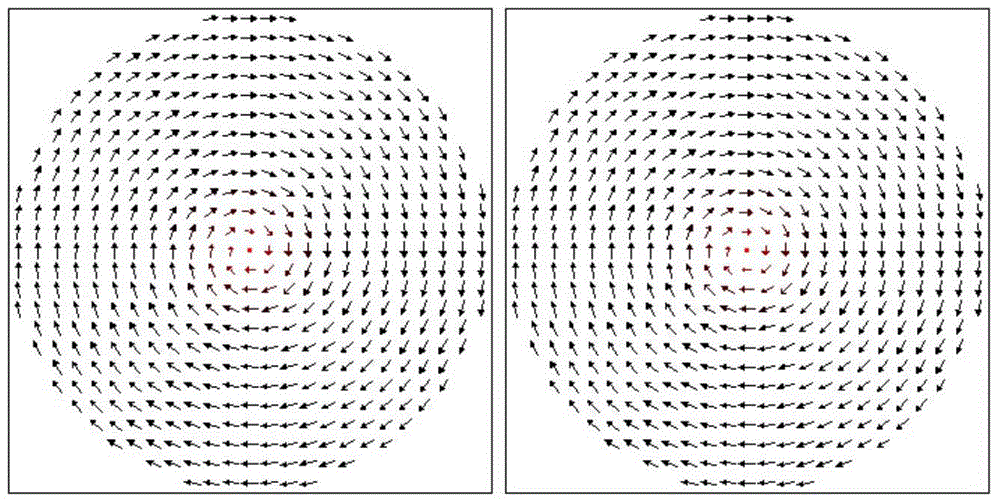

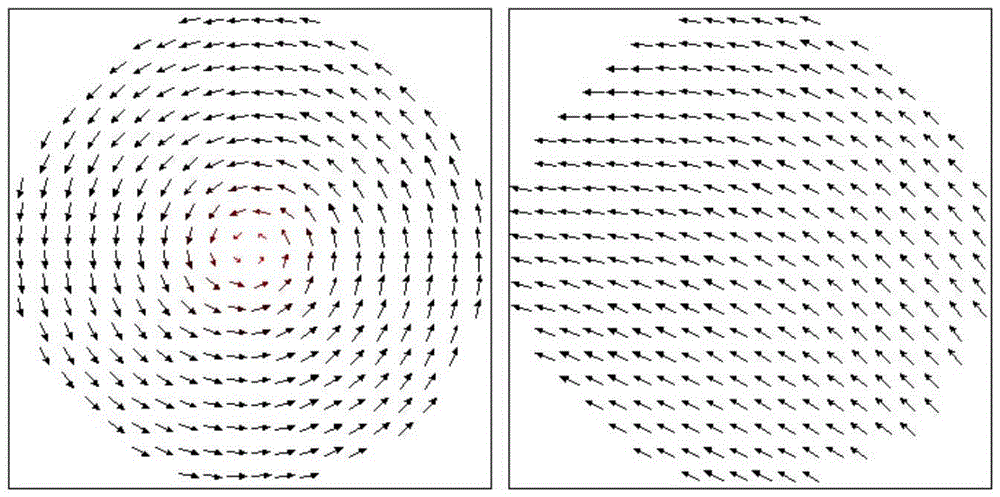

[0018] As shown in Figure 2, it can be seen from the simulation results that when the diameter is greater ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com