A main transformer online regenerative respirator with a frequency conversion control microwave heating device and its use method

A technology of a microwave heating device and a main transformer respirator, applied in microwave heating, chemical instruments and methods, separation methods, etc., can solve problems such as main transformer explosion, accident expansion, and main transformer breathing airflow change, and achieve good heating efficiency, Ensure safe operation and increase the effect of microwave radiation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

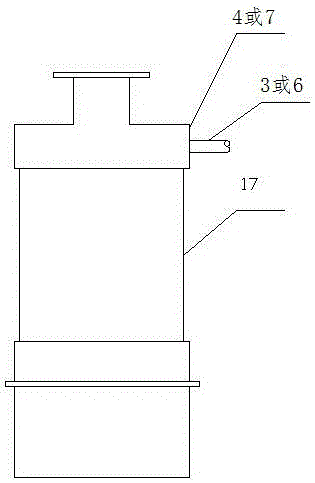

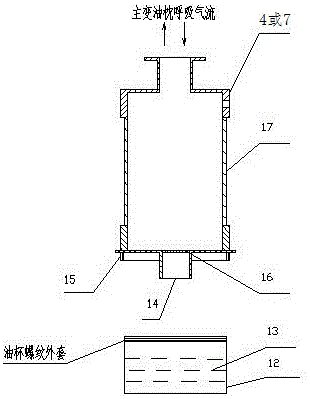

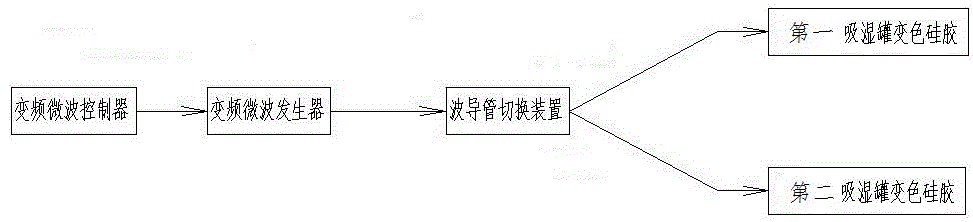

[0036] This embodiment provides a main transformer online regenerative respirator with a microwave heating device controlled by frequency conversion, including a main transformer body 19 and an oil conservator 11 connected thereto. The upper part of the oil conservator 11 is connected to the upper end of a main transformer breathing pipe 10, The lower end of the main transformer breathing tube 10 is connected to a three-way pipe 9, and the remaining two ends of the three-way pipe 9 are respectively connected to the first moisture absorption tank 4 and the second moisture absorption tank 4 through the first valve 5 and the second valve 8. Tank 7 , the first moisture absorption tank 4 and the second moisture absorption tank 7 are connected to a frequency conversion control microwave heating device, and the frequency conversion control microwave heating device is electrically connected to a frequency conversion microwave controller 20 .

[0037]In this embodiment, the frequency co...

Embodiment 2

[0042] This embodiment provides a method for using the main transformer online regenerative respirator with frequency conversion control microwave heating device as described in Embodiment 1, which specifically includes the following steps:

[0043] Step S1: the first valve 5 is opened, and the first moisture-absorbing tank 4 is used as the main transformer respirator, and communicates with the breathing pipe of the main transformer; the second valve 8 is closed, and the second moisture-absorbing tank 7 is connected with the main transformer The breathing tube 10 is isolated as a backup respirator;

[0044] Step S2: When the main transformer body 19 is in normal operation, the oil surface of the oil conservator 11 expands with heat and contracts with temperature, thereby producing respiration, and the breathing airflow of the transformer oil inside the oil conservator 11 breathes through the main transformer Pipe 10 enters the main transformer respirator;

[0045] Step S3: Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com