Electrical connection self-locking terminal

An electrical connection and self-locking technology, which is applied in the direction of conductive connection, connection, electrical components, etc., can solve the problems of wire head connection safety life, reliability difficult to be guaranteed, electrical accidents, line failures, etc., to achieve fast and convenient connection Guaranteed connection quality, safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

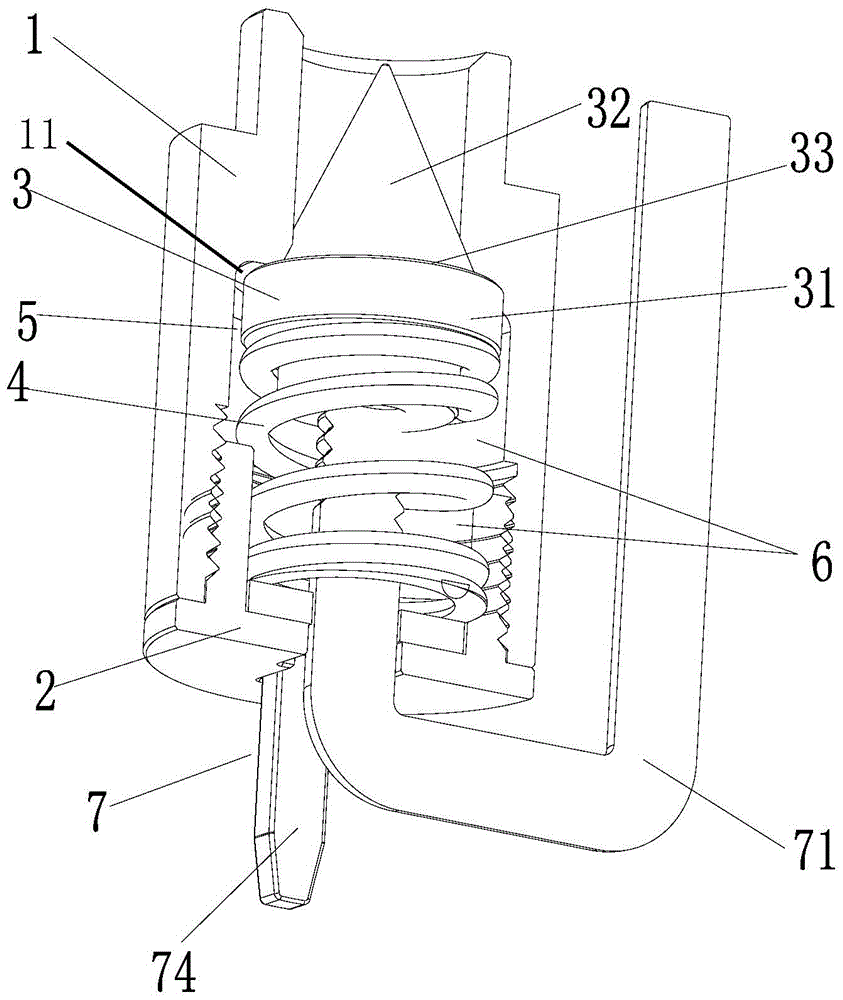

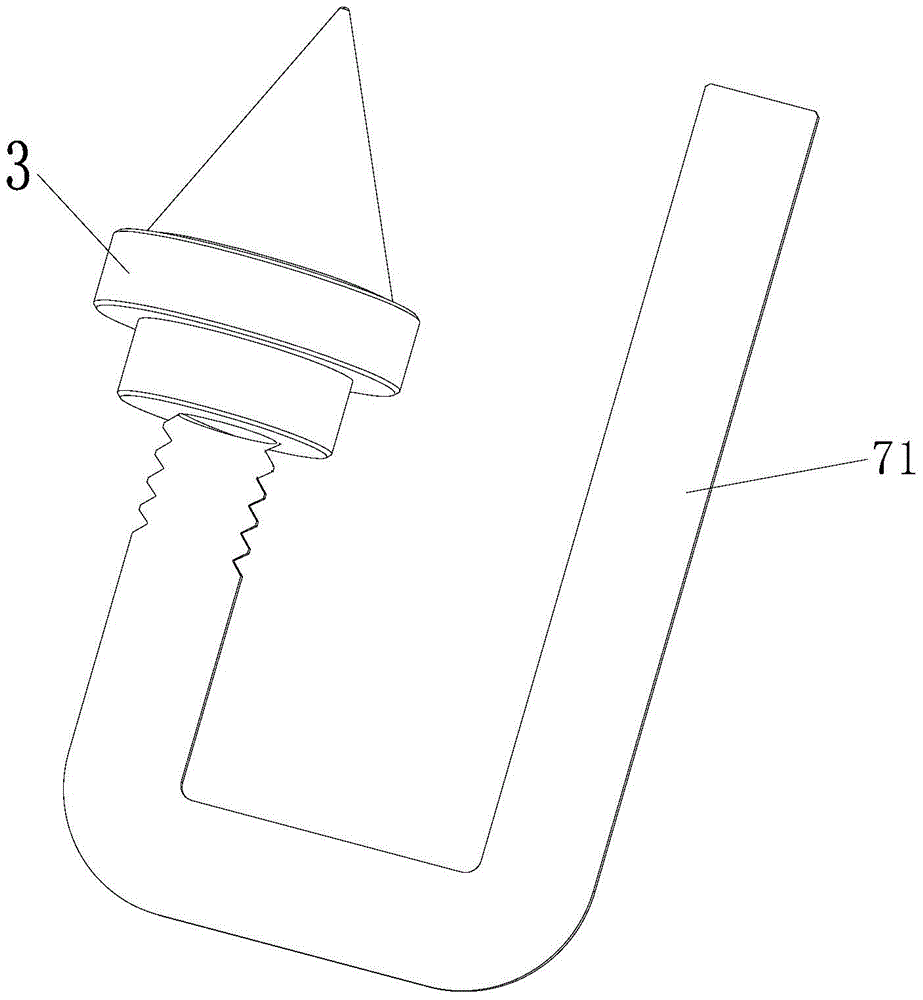

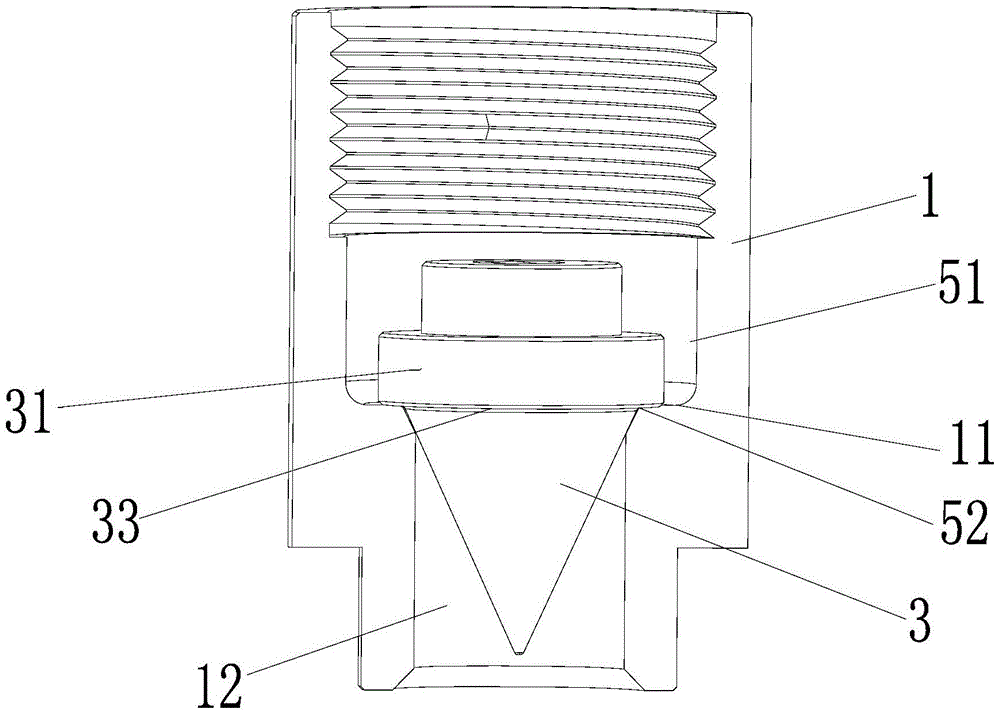

[0031] Figure 1 to Figure 4 , shows an embodiment of the present invention for the connection of electric wires and electrical equipment. The backseat of this mode is a pass structure. It includes the wire inlet seat 1, the guide pressure taper shaft 3 axially installed in the wire inlet seat, the back seat 2 and the spring 4, the wire inlet seat 1 is axially connected with the rear seat 2, and the wire inlet seat 1 and the back seat 2 can be threaded, and can also be integrated. The guide thread taper shaft 3 includes a pressure receiving portion 31 and a branching taper portion 32, a first step 33 is provided between the pressure receiving portion 31 and the branching taper portion 32, and the wire inlet seat 1 has a A second step 11 corresponding to a step 33, there is a gap 5 between the wire inlet seat 1 and the guide crimping cone shaft 3 for the wire to enter, and the wire inlet seat 1 and the rear seat 2 are provided with a mounting In the spring chamber 6 of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com