A Wide Temperature Ring Laser Diode Pumped Laser and Its Design Method

A technology of laser diodes and pump lasers, applied in the field of wide-temperature ring laser diode pump lasers, can solve the problem of increasing the complexity, volume and weight of laser systems, unfavorable laser miniaturization, lightweight design, and reducing the reliability of laser system operation and anti-interference problems, to achieve the effect of compact structure, reduced volume and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

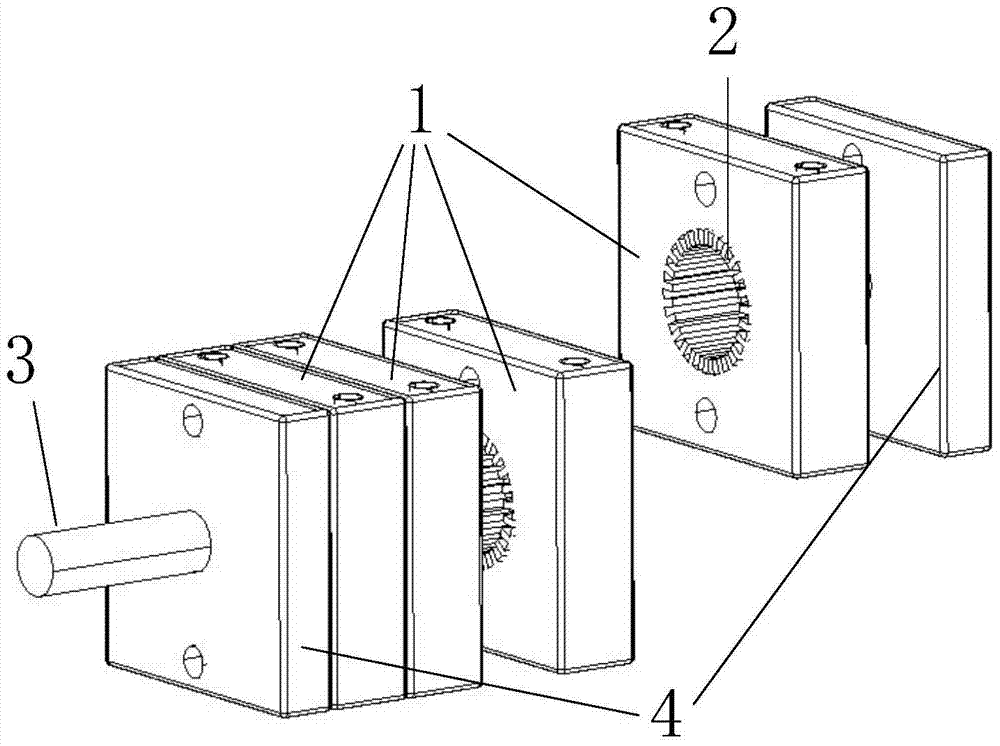

[0045] Such as figure 1 , figure 2 As shown, a wide-temperature ring laser diode pump laser includes a cooling heat sink 1 , a ring bar array 2 , a gain medium 3 , a housing 4 , and a Q-switched crystal 5 . Both the gain medium 3 and the Q-switching crystal 5 are cylindrical, and the casing 4 is set outside the cooling heat sink 1, the cooling heat sink 1 is a cuboid with a through hole in the center, and the annular bar The bar array 2 is fixedly connected to the surface of the round hole of the cooling heat sink 1, the radius of the gain medium 3 is smaller than the radius of the round hole of the cooling heat sink 1, and the gain medium 3 passes through the circle of the cooling heat sink 1 Holes, the axis of the gain medium 3 coincides with the axis of the ring bar array 2, the ring bar array 2 includes bars of at least two emission wavelengths, the intervals between adjacent bars are the same, and the adjacent bars The difference in the number of bars between the bars ...

Embodiment 2

[0058] Select Nd:YAG as the gain medium 3, and Cr:YAG as the Q-switching crystal 5, and design according to the bar array 2 design method of Embodiment 1 of the present invention, the steps are as follows:

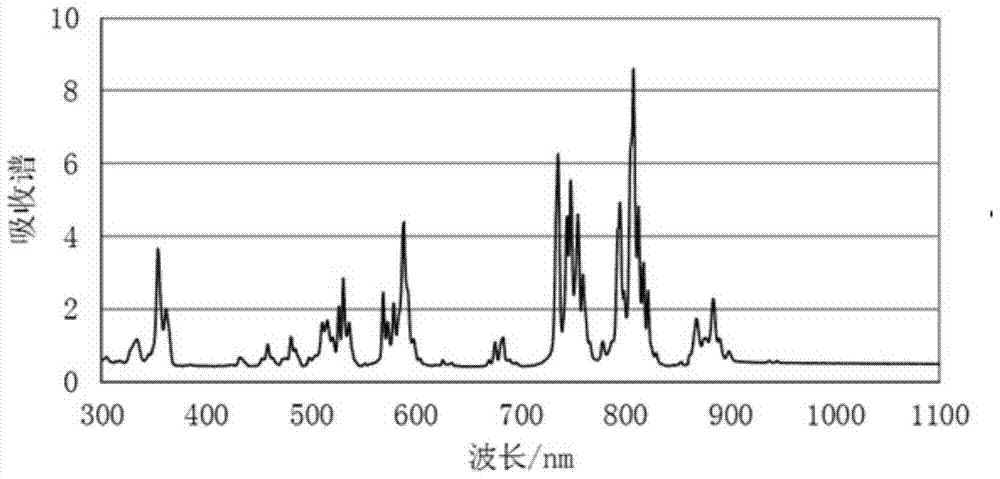

[0059] (1) Obtain the absorption spectrum curve function σ(λ) of the laser crystal as the gain medium 3 by measurement, such as image 3 As shown, where the independent variable λ is the emission wavelength of the bar, the wavelength corresponding to the absorption peak of the laser crystal is 808nm, the emission wavelength range of the selected bar is 790-826nm, and the wavelength range is discretized as 790±1.5nm, 793nm ±1.5nm···826±1.5nm, a total of 13 value segments;

[0060] (2) Determine the required working temperature range from -20°C to 50°C, and measure the single-bar emission power function p(T) of each emission wavelength within the above temperature range, such as Figure 4 As shown, the temperature drift coefficient of the emission wavelength of the bar is k...

Embodiment 3

[0069] Select Nd: glass as the gain medium 3, Cr: YAG as the Q-switching crystal 5, and design according to the bar array 2 design method of Embodiment 1 of the present invention, the steps are as follows:

[0070] (1) Obtain the absorption spectrum curve function σ(λ) of the laser crystal as the gain medium 3 by measurement, such as Figure 8 As shown, among them, the independent variable λ is the emission wavelength of the bar, the wavelength corresponding to the absorption peak of the laser crystal is 802nm, the emission wavelength range of the selected bar is 784-820nm, and the wavelength range is discretized as 784±1.5nm, 787nm ±1.5nm···820±1.5nm, a total of 13 value segments;

[0071] (2) Determine that the required operating temperature range is -20°C to 50°C, and measure the single-bar emission power function p(T) of each wavelength within the above temperature range, such as Figure 4 As shown, the temperature drift coefficient of the emission wavelength of the bar i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com