Light beam control component, light emitting device, surface light source device and display device

A technology for beam control components and light-emitting elements, which is applied in the directions of light sources, electric light sources, optical elements, etc., can solve the problems of uneven brightness, excess light, and large loss of light, and achieves less uneven brightness and light utilization efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0079] (Structure of surface light source device and light emitting device)

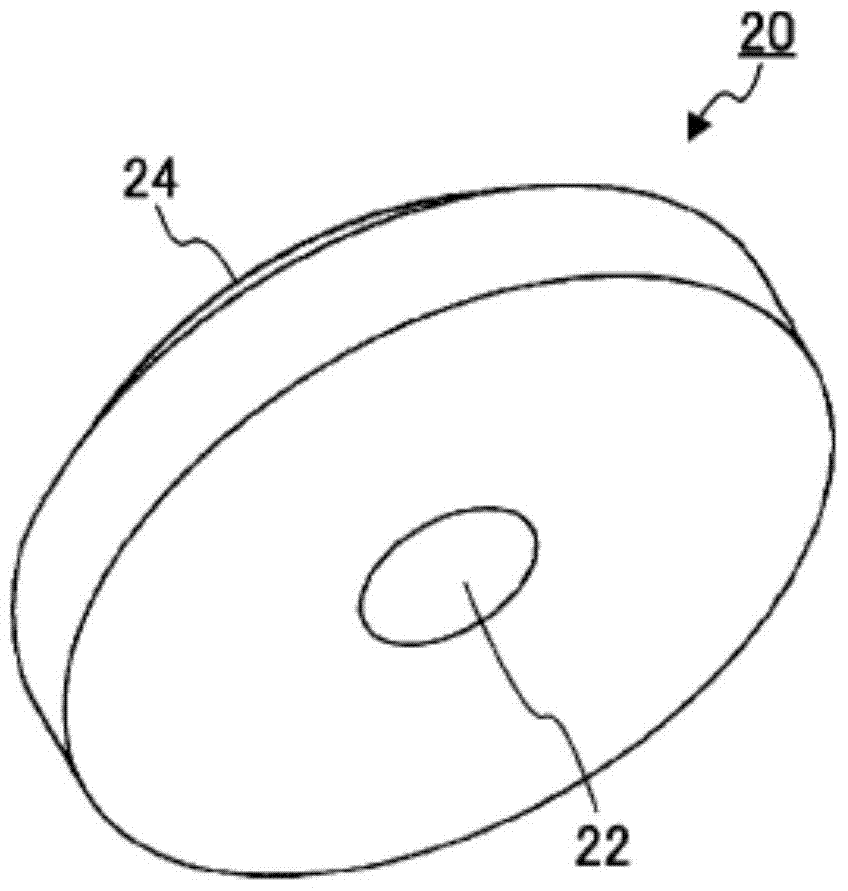

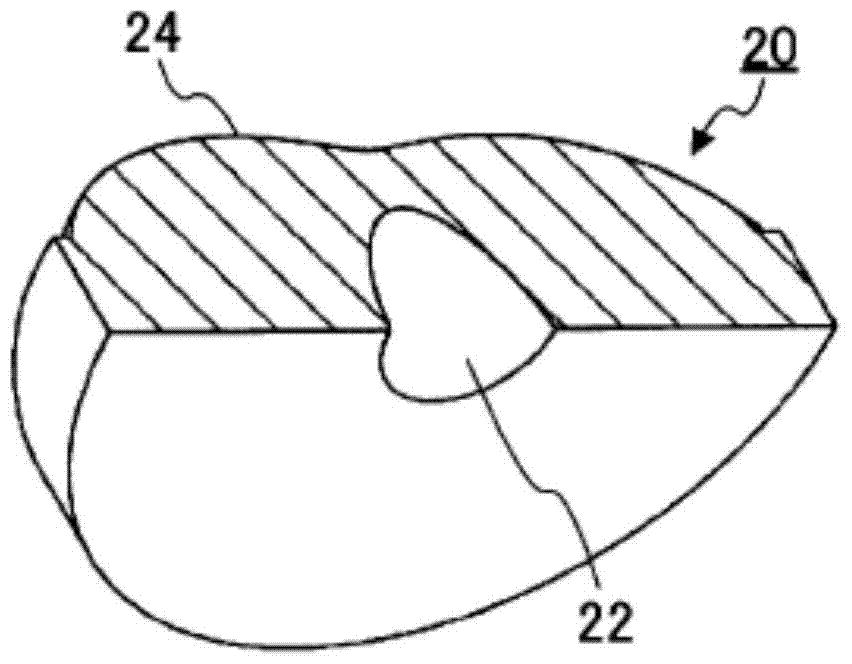

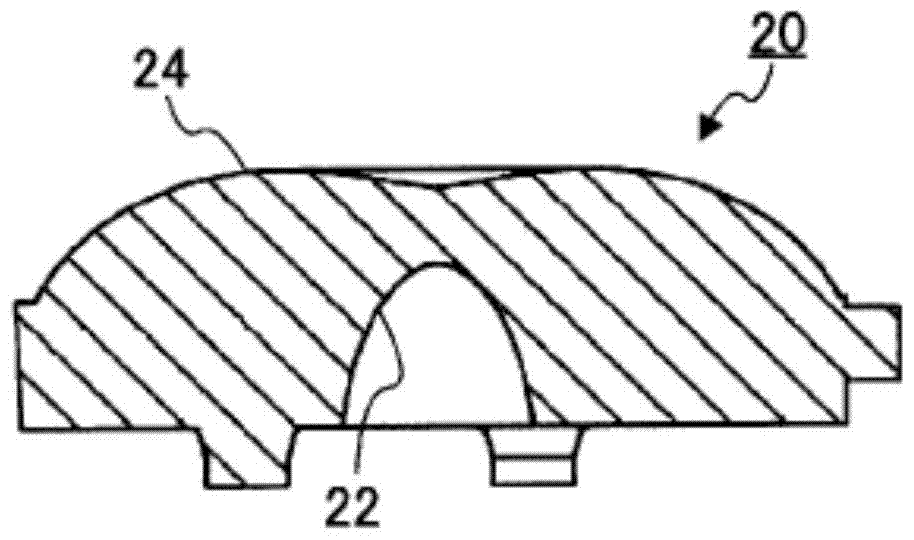

[0080] Figure 5~ Figure 7 It is a figure which shows the structure of the surface light source device of Embodiment 1. Figure 5A is a top view, Figure 5B is the main view. Figure 6A yes Figure 5B A cross-sectional view of line A-A is shown, Figure 6B yes Figure 5A The section view of line B-B is shown. Figure 7 will be Figure 6B An enlarged partial cross-sectional view of a part of .

[0081] As shown in FIGS. 5 and 6 , the surface light source device 100 according to Embodiment 1 includes a housing 110 , a plurality of light emitting devices 200 , and a light diffusion member 120 . A plurality of light emitting devices 200 are arranged in a matrix on the bottom plate 112 of the casing 110 . The inner surface of the bottom plate 112 functions as a diffuse reflection surface. In addition, an opening is provided in the top plate 114 of the casing 110 . The light-diffusing member 120...

Embodiment approach 2

[0126] (Structure of surface light source device and light emitting device)

[0127] The surface light source device and light emitting device of Embodiment 2 are similar to those shown in FIGS. Figure 7 The difference between the surface light source device 100 and the light emitting device 200 of the first embodiment shown is that the light flux control member 400 of the second embodiment is provided instead of the light flux control member 300 of the first embodiment. Therefore, in this embodiment, only the light flux controlling member 400 of Embodiment 2 will be described.

[0128] (Structure of Beam Control Parts)

[0129] 16 and 17 are diagrams showing the configuration of a light flux control member 400 according to the second embodiment. Figure 16A It is a perspective view seen from the inside, Figure 16B It is a sectional perspective view seen from the back side. Figure 17A is a top view, Figure 17B is the main view, Figure 17C is a bottom view, Figure 17...

Embodiment approach 3

[0138] (Structure of surface light source device and light emitting device)

[0139] The surface light source device and the light emitting device according to Embodiment 3 have the light flux control member 500 of Embodiment 3 instead of the light flux control member 300 of Embodiment 1, and are similar to FIGS. Figure 7 The surface light source device 100 and the light emitting device 200 of Embodiment 1 shown are different. Therefore, in this embodiment, only the light flux control member 500 of Embodiment 3 will be described.

[0140] (Structure of Beam Control Parts)

[0141] Figure 20 It is a sectional view of the light flux controlling member 500 according to the third embodiment.

[0142] Such as Figure 20 As shown, the light beam control component 500 has a concave portion 310 , an incident surface 320 , an outgoing surface 330 , a back surface 340 , a reflective portion 350 , a flange portion 560 and a plurality of leg portions 370 . Components that are the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com