Gear flowmeter

A flowmeter and gear technology, applied in the field of gear flowmeters, can solve the problems of high starting torque, influence, and inaccurate measurement, and achieve the effect of reducing starting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

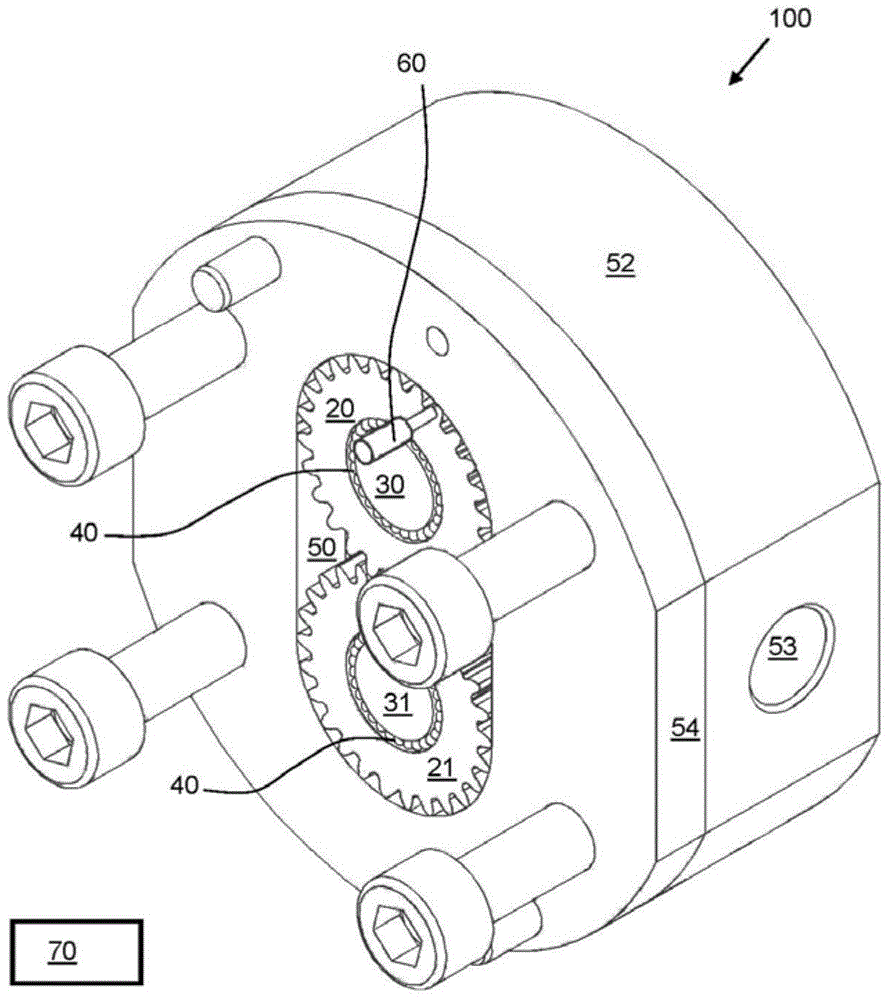

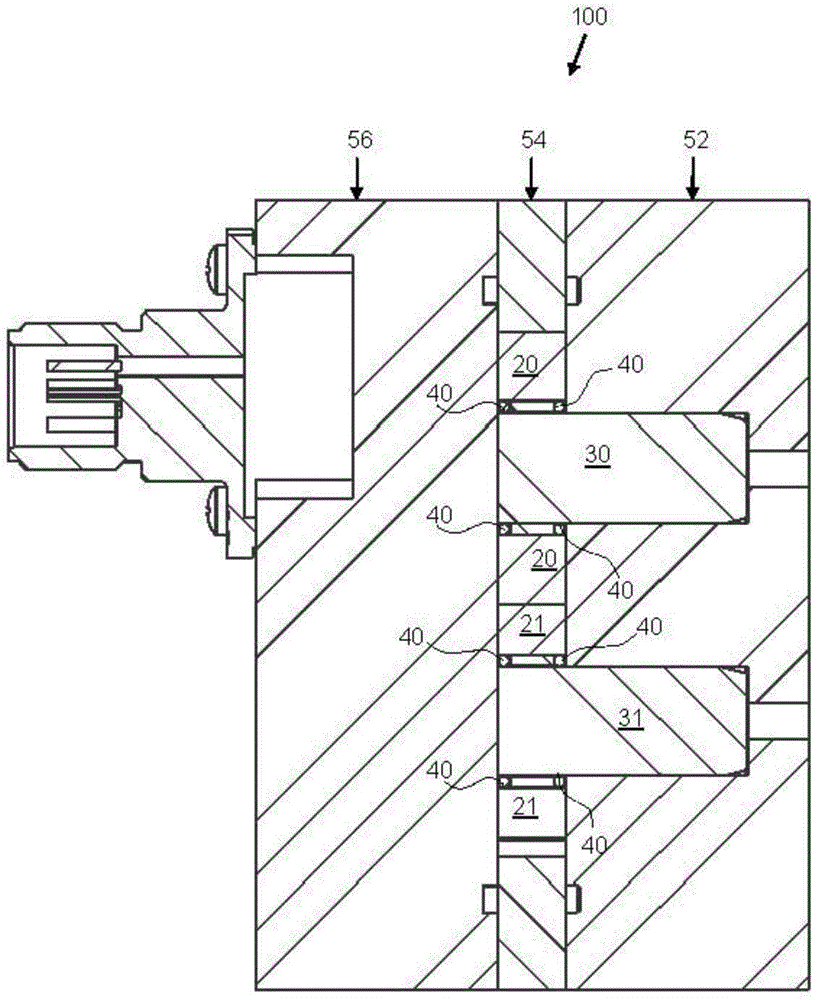

[0057] In accordance with the present invention, an exemplary embodiment of a gear flow meter 100 initially refers to figure 1 with figure 2 describe. figure 1 Then a perspective view of the gear flowmeter 100 is shown, figure 2 A sectional view thereof is then shown, which extends along the axis of rotation of the gear flowmeter 100 .

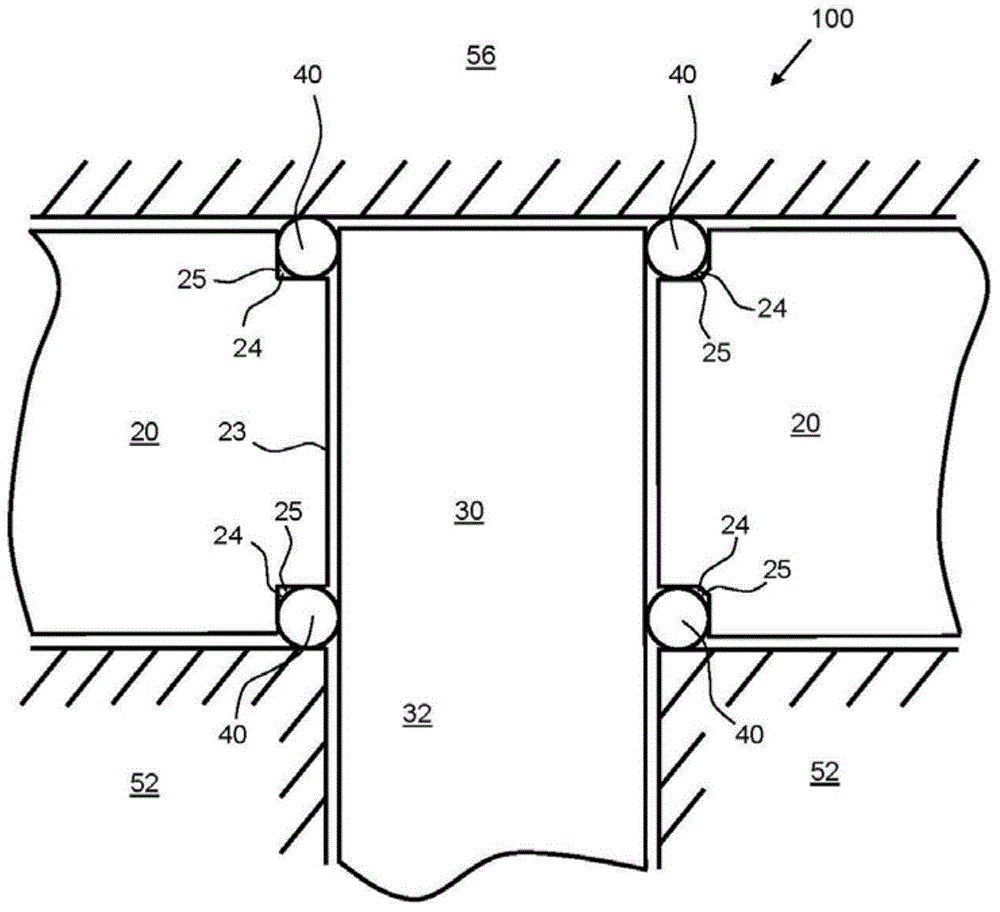

[0058] As necessary components, the gear flowmeter 100 has a gear chamber 50, two measuring gears 20 and 21 disposed therein, respective rotating shafts 30 and 31 of the two measuring gears 20 and 21 and rolling elements for mounting the measuring gears 20 and 21. Element 40.

[0059] In principle, a single measuring gear 20 is also sufficient, or there are more than two measuring gears.

[0060] Preferably, the fluid can only traverse the gear chamber 50 between adjacent teeth of one of the measuring gears 20, 21 on the walls of the gear chamber. Through this flow, the fluid can set the measuring gears 20, 21 in motion. As soon as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com