A grinding wheel production material feeding press screen system

A press net and grinding wheel technology, applied in the direction of metal processing equipment, grinding equipment, grinding/polishing equipment, etc., can solve the problems such as the reduction of the strengthening effect of the grinding wheel, the damage of the mesh, and the unguaranteed quality of the grinding wheel, so as to avoid the mesh The effects of prying offset, improved grinding wheel quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

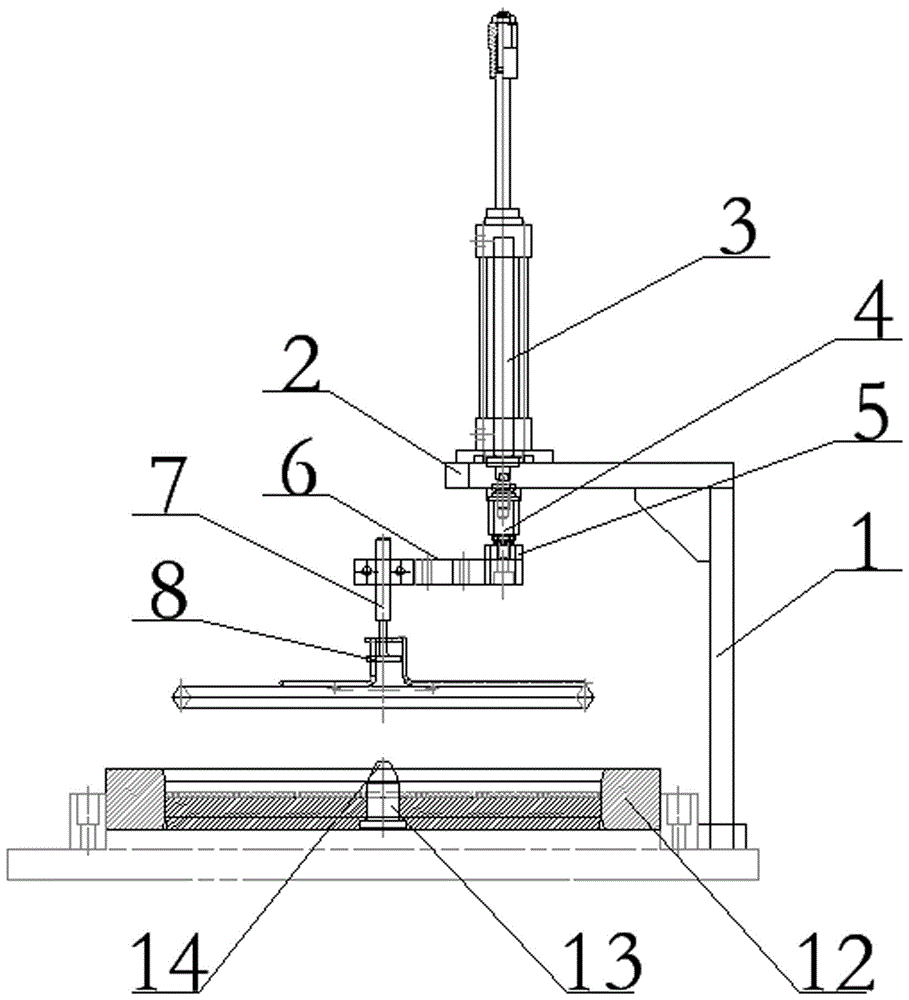

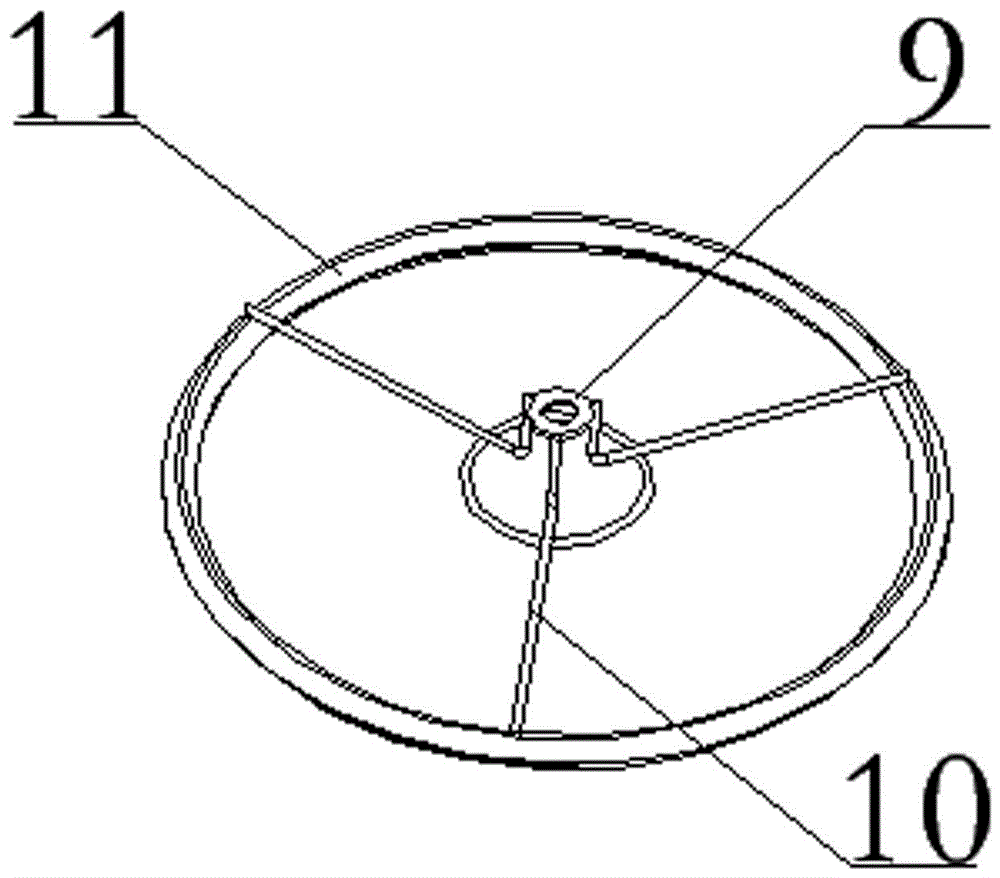

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

[0013] Figure 1-2 As shown, a feeding press system for grinding wheel production includes a press support 1, a cylinder support plate 2, a lifting cylinder 3, a lifting rod 4, a movable joint 5, a lifting connection block 6, a boom 7, a lifting ring 8, and an internal pressure ring 9 , The connecting rib 10 and the outer pressure ring 11. The grinding wheel forming mold 12 is set on the grinding wheel forming machine in a passive rotating state. The center of the grinding wheel forming mold 12 is provided with a mandrel 13, and the top of the mandrel 13 is provided with a cone head 14; The support plate 2 supports the lifting cylinder 3, the lifting cylinder 3 is connected to the lifting connection block 6 through the movable joint 5, the lifting connection block 6 is connected to the bottom of the lifting cylinder 3 and the lifting rod 4 pierced on the cylinder suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com