A hybrid robot device for car body spraying

A technology of automobile body and robot, applied in the direction of injection device, manipulator, program control manipulator, etc., can solve the problems of difficult equipment function, digestion and maintenance, etc., and achieve the effect of large working space, easy modularization and symmetrical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

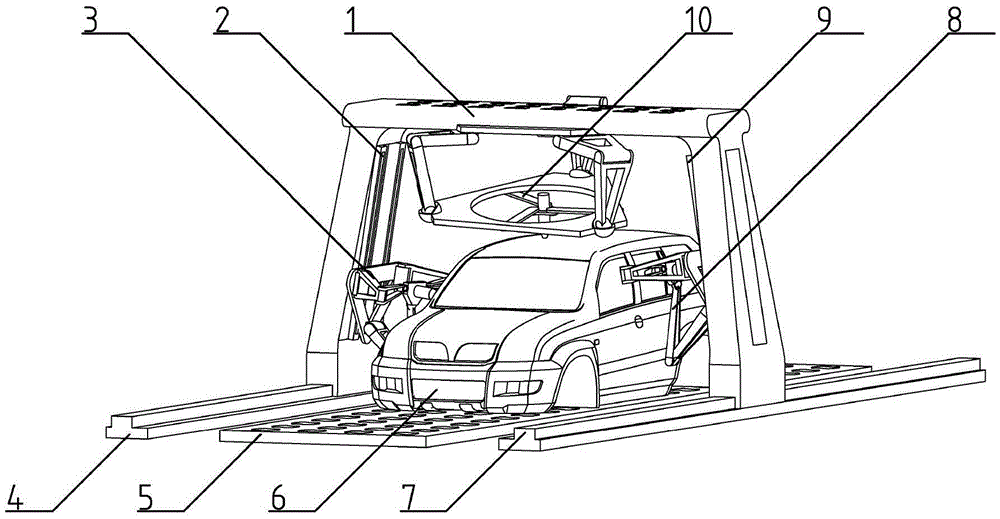

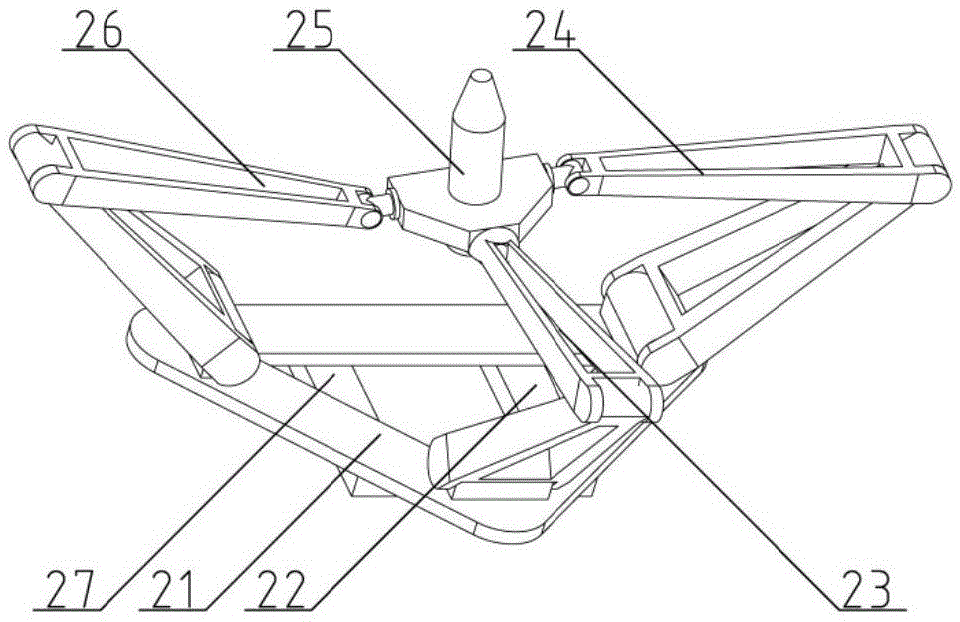

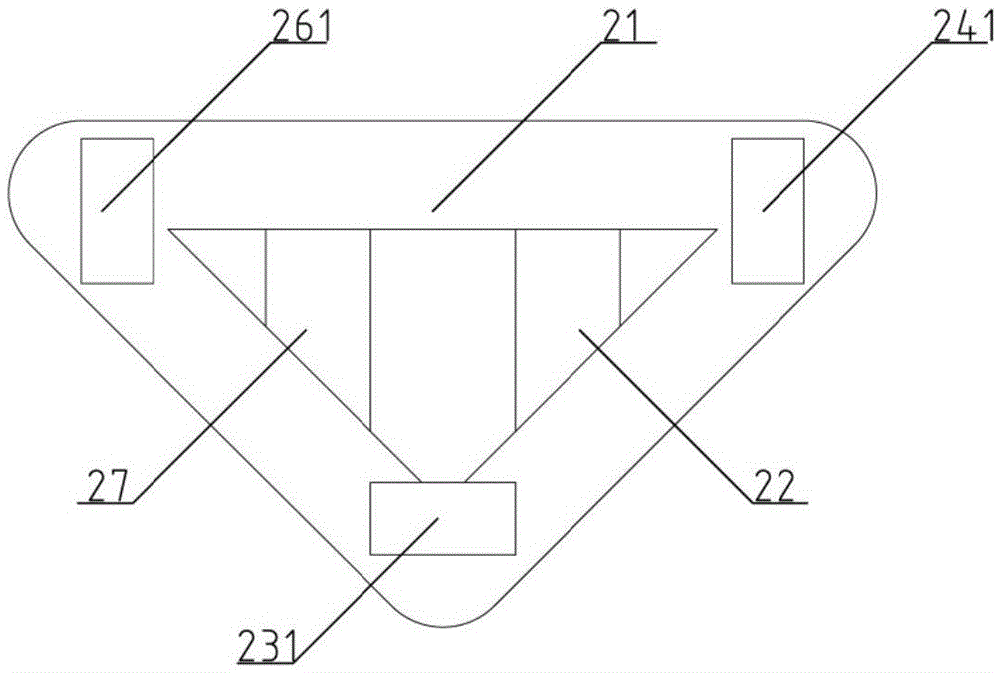

[0027] figure 1 The three-dimensional schematic diagram of the embodiment of the hybrid spraying robot device provided by the present invention, the robot device includes a gantry frame 1, a left ground horizontal guide rail 4, a right ground horizontal guide rail 7, a left column guide rail 2, a right column guide rail 9, Three degrees of freedom parallel mechanism 3, right three degrees of freedom parallel mechanism 8 and six degrees of freedom parallel mechanism 10; the left ground horizontal guide rail 4 and the right ground horizontal guide rail 7 are installed in parallel on the horizontal ground; the gantry frame 1 Installed on the left ground horizontal guide rail 4 and the right ground horizontal guide rail 7, it can realize its horizontal reciprocating movement on the guide rail; the left column guide rail 2 and the right column guide rail 9 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com