Nail beautifying foil production equipment

A technology for producing equipment and manicure foils, applied in layered products, manicure or pedicure tools, clothing, etc. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

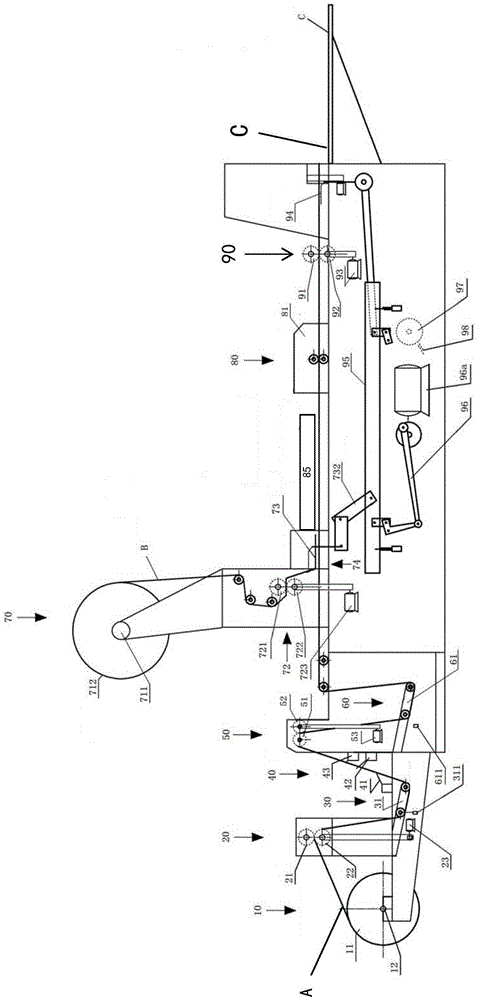

[0023] like figure 1 As shown, a preferred embodiment of the nail art foil production equipment provided by the invention includes:

[0024] The aluminum foil roll 11 is placed on the frame by the support roller 12, and the aluminum foil strip on it passes through the embossing mechanism 20, the first feeding mechanism 30, the hemming mechanism 40, the guiding mechanism 50, and the second feeding mechanism 60 in sequence , bonding mechanism 85, leveling mechanism 80, pulling mechanism 90 and rear cutter 94;

[0025] Sliver / non-woven roll 712, which is placed on the frame by another support roller 711, the sliver / non-woven on it (this non-woven preferably needle-punched non-woven) is sent forward by conveying mechanism 72 Cutter 73, the front cutter 73 is located at the upstream position of the bonding mechanism 85;

[0026] Wherein: when the front cutter 73, the adhesive mechanism 85 or the rear cutter 94 work, the aluminum foil roll 11 and the sliver / non-woven fabric roll 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com