Energy feedback control method for full electric vehicle

A technology of energy feedback and control methods, applied in electric vehicles, electric braking systems, vehicle components, etc., can solve the problem of increasing vehicle costs, increasing vehicle curb weight, driving range and energy consumption levels cannot be optimally improved, etc. problem, to achieve the effect of extending driving range, reducing energy consumption, and realizing energy feedback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

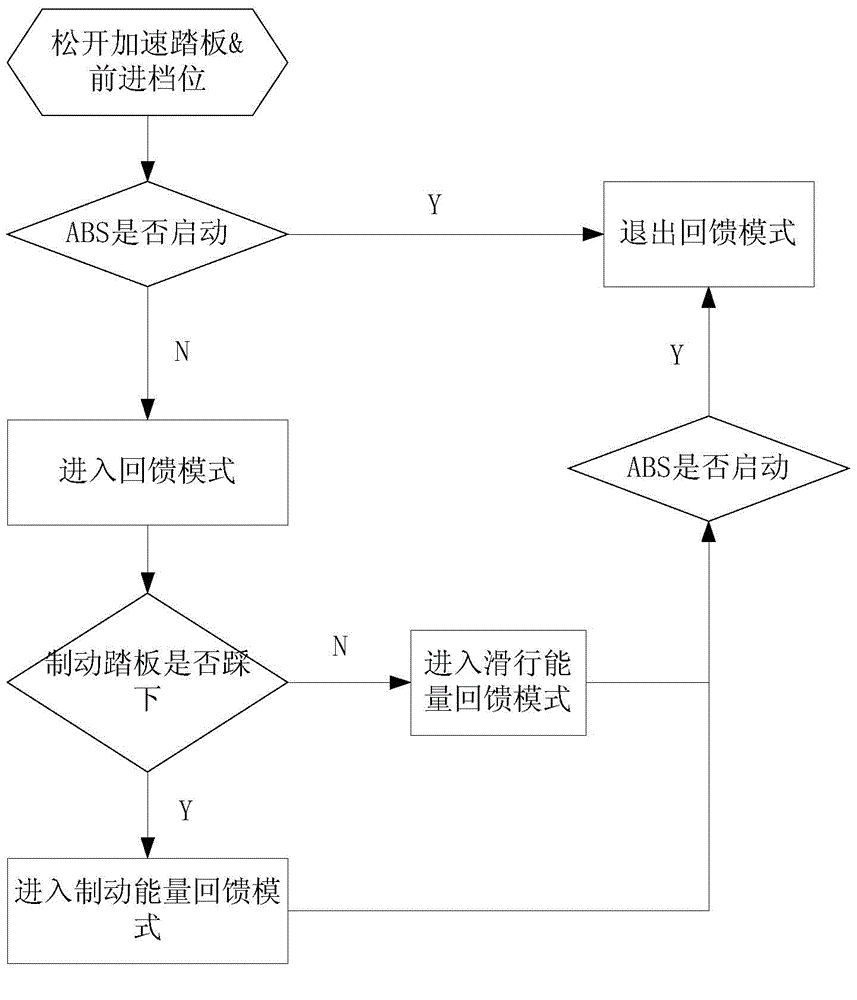

[0029] The main flow chart of the energy feedback control method of the pure electric vehicle of the present invention is as follows figure 1 As shown, the specific steps are as follows:

[0030] Steps to enter the feedback mode: on the premise that the accelerator pedal is released and the vehicle is in the forward gear, judge whether the anti-lock braking system ABS is activated. If it is activated, it will not enter the feedback mode; if it is activated, it will enter the feedback mode;

[0031] Feedback mode selection steps: After entering the feedback mode, judge whether the brake pedal is stepped on. If it has been stepped on, the vehicle enters the brake feedback mode. The direction of the brake feedback energy flow is the vehicle braking deceleration kinetic energy---motor mechanical energy- --Motor electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com