A bar transfer vehicle

A transfer vehicle, bar material technology, applied in transportation and packaging, hoisting devices, conveyors, etc., can solve the problems of high production workshop configuration requirements, increase production and manufacturing costs, and cannot be suitable for object transfer, so as to make up for poor flexibility, The effect of improving efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

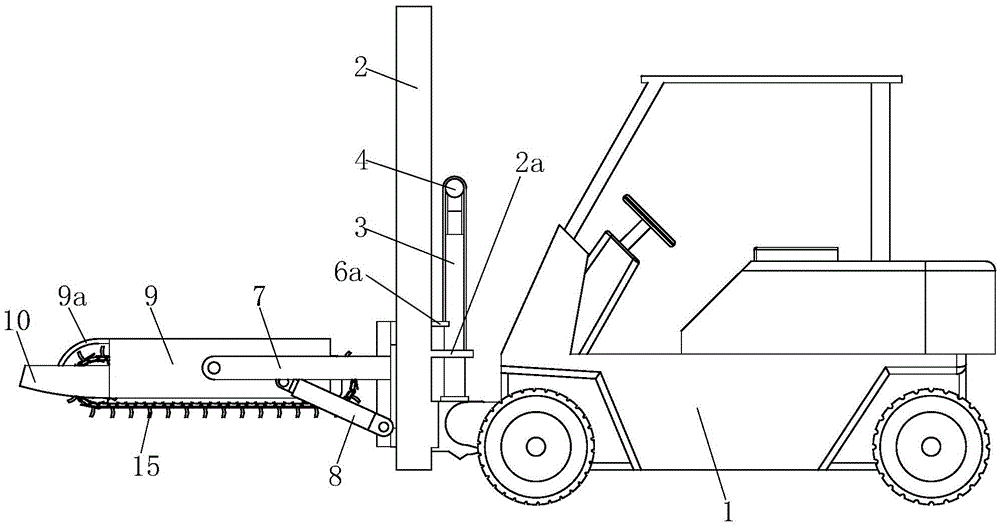

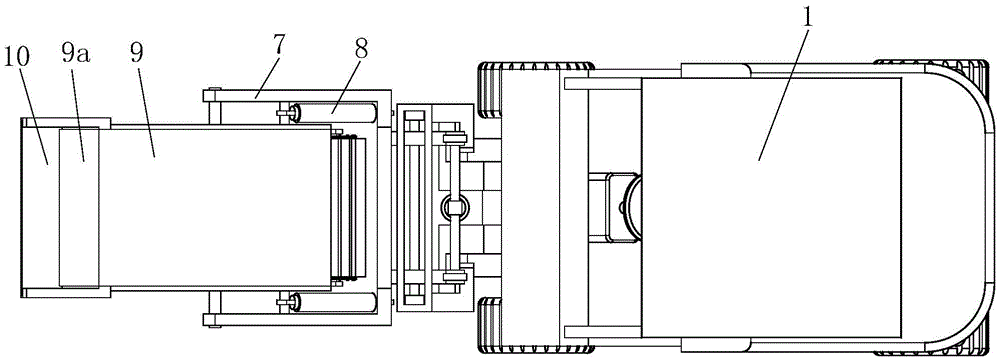

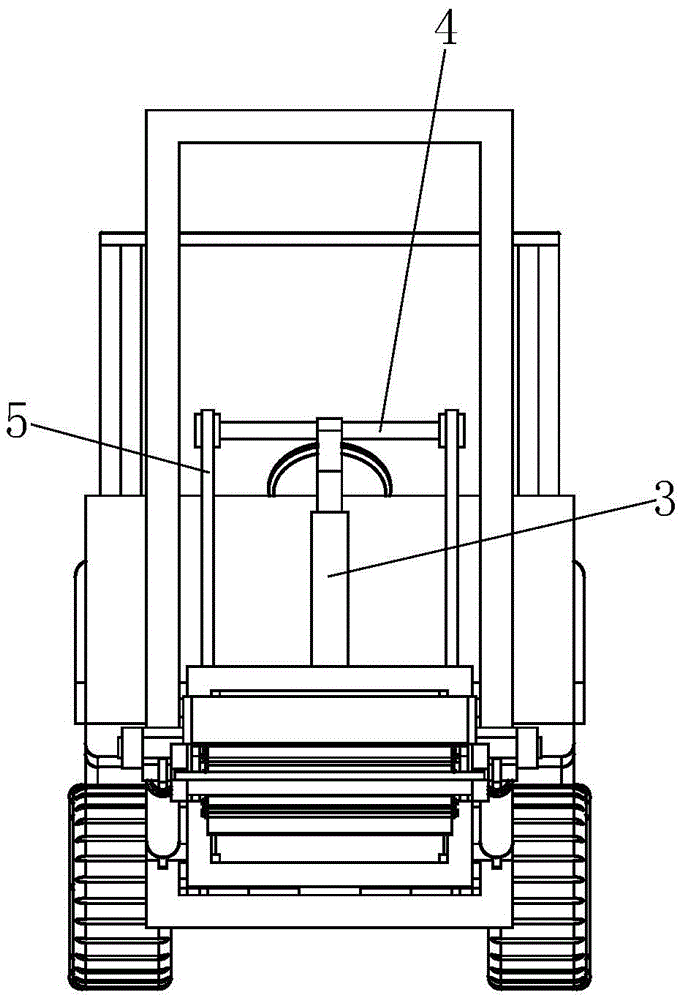

[0024] Such as Figure 1 to Figure 9 As shown, a bar material transfer vehicle includes a car body 1, the left end of the car body 1 is connected with a lifting device, the left side of the lifting device is connected with an angle adjustment device, and the left side of the angle adjustment device is connected with a Retrieval storage unit. The operator can control the present invention by sitting on the car body 1. The bar is stacked on the ground in advance, and the operator can start the lifting device to adjust the working height of the angle adjustment device, the reclaiming storage device, and the unloading storage device. When it is attached to the ground, the retrieving storage device can be started to shovel the bar into the retrieving storage device to realize retrieving and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com