Cigarette paper added with colorful fibers and production method of cigarette paper

A production method and technology for cigarette paper, which are applied in the directions of natural cellulose pulp/paper, fiber raw material processing, paper, etc., can solve the problems of uncleanness, environmental protection, excessive contrast, etc., and achieve improved appearance, enhanced visual effect, and good anti-counterfeiting. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

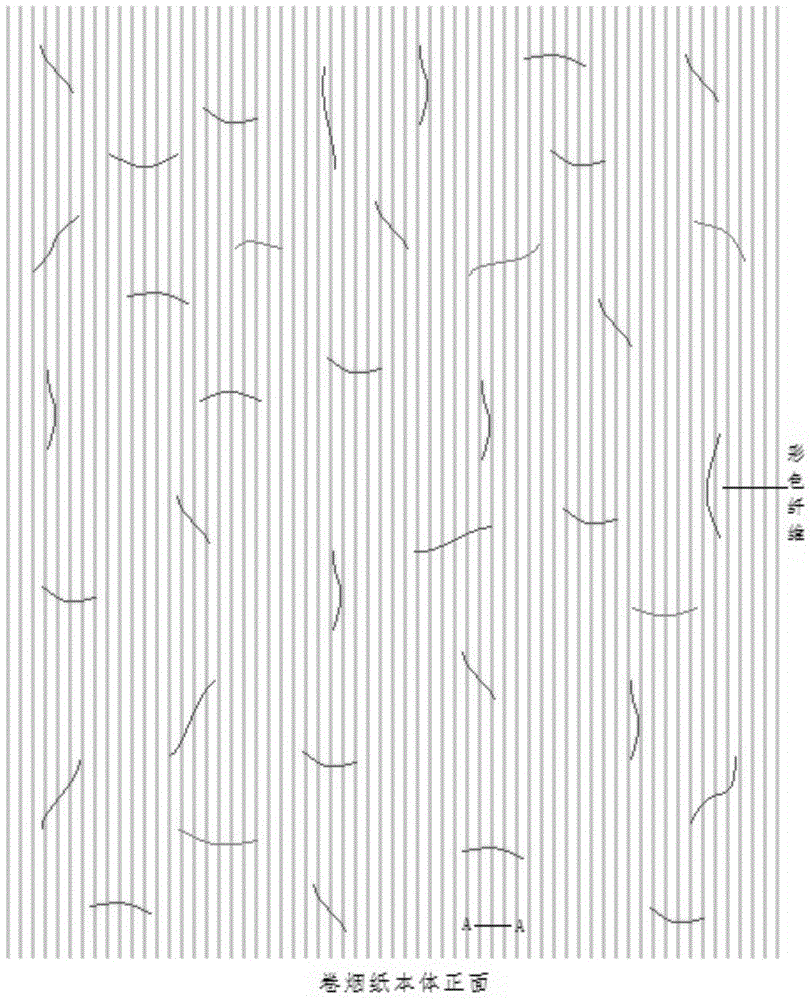

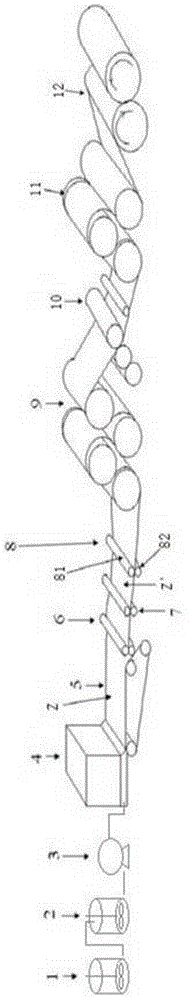

[0040] Such as image 3 Shown: A method for producing cigarette paper with colored fibers, comprising the following steps:

[0041] 1) Place natural fibers with a length of 2 to 8mm in the dye vat 1 filled with plant-extracted natural pigments or food-grade dyes, carry out dyeing and fixation, and then carry out cleaning treatment until the colored fibers do not fade, ensuring that the The fiber color does not pollute the body of the cigarette paper, that is, colored fibers are obtained;

[0042] 2) Dispersing the colored fiber obtained in step 1) to fully disperse it to obtain a single colored fiber;

[0043] 3) Add the colored fibers dispersed in step 2) into the mixed paper slurry 2 used for cigarette paper production, and further disperse the colored fibers through an even double disc mill 3 to ensure that the colored fibers exist in a single state in the mixed paper slurry, wherein , the colored fibers account for 0.5‰ of the weight of the mixed paper slurry;

[0044] ...

Embodiment 2

[0049] The steps of this embodiment and embodiment 1 are basically the same: the difference is:

[0050] 1) screening and cutting to obtain natural colored fibers with a length of 2 to 8 mm, that is, to obtain colored fibers;

[0051] 2) The colored fibers account for 0.5‰ of the weight of the mixed paper slurry;

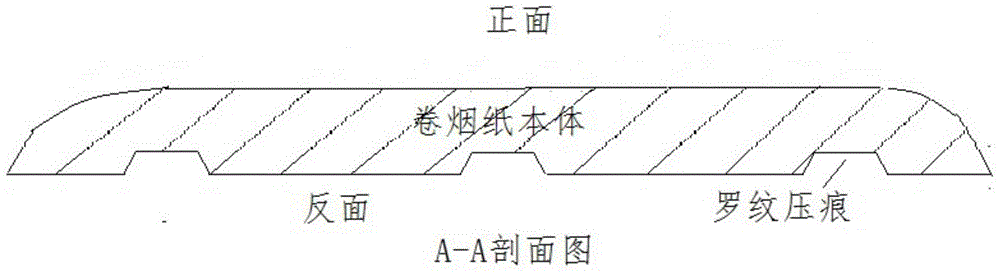

[0052] 3) The angle between the extension direction of the indentation and the longitudinal direction of the cigarette paper is α, and α is 90°; the indentation is a transverse thread.

Embodiment 3

[0054] The steps of this embodiment and embodiment 1 are basically the same: the difference is:

[0055] 1) The colored fibers account for 3.0‰ of the weight of the mixed paper slurry;

[0056] 2) The angle between the extending direction of the indentation and the longitudinal direction of the cigarette paper is α, and α is 30°; the indentation is oblique thread.

[0057]In the actual production process, the colored fibers account for 0.75‰, 1.0‰, 1.25‰ or 2.0‰ of the weight of the mixed paper slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com