Automatic dedusting and demoulding agent brushing device for tunnel steel trolley

A technology of automatic dust removal and steel formwork trolley, which is applied in tunnels, tunnel linings, shaft equipment, etc., and can solve problems such as poor working environment, poor quality, and heavy steel formwork trolleys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] 1. Equipment manufacturing

[0028] (1) Manufacture of automatic dust removal device

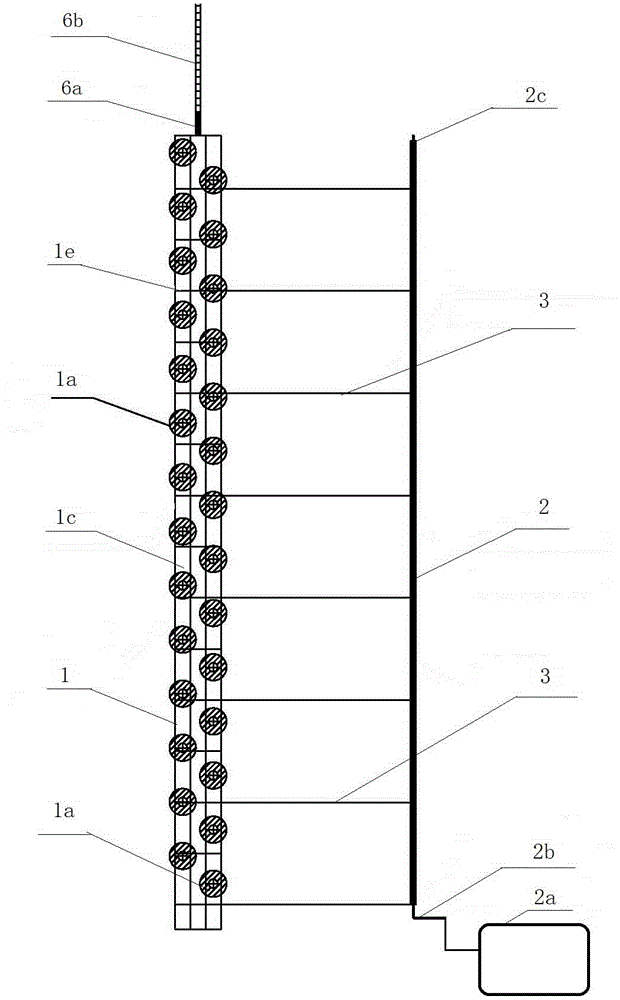

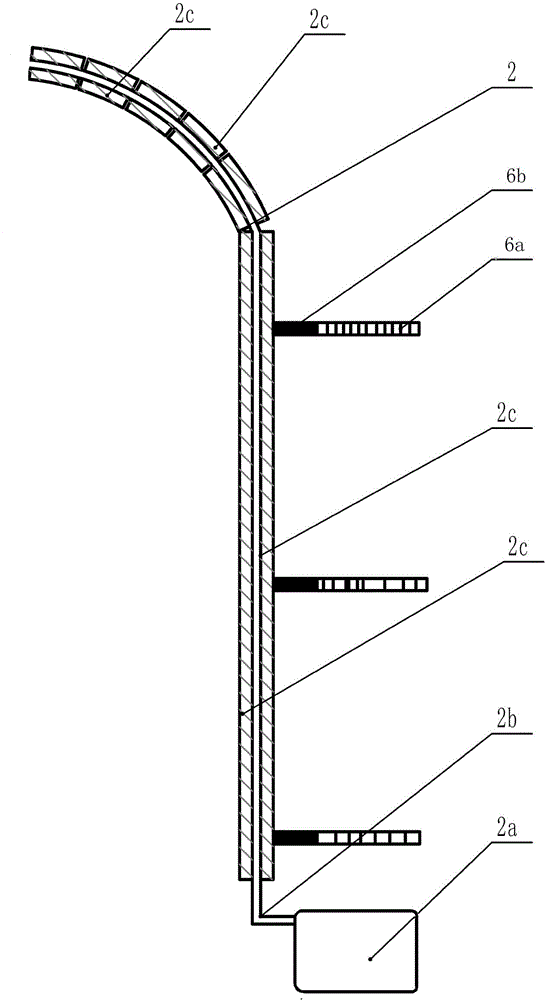

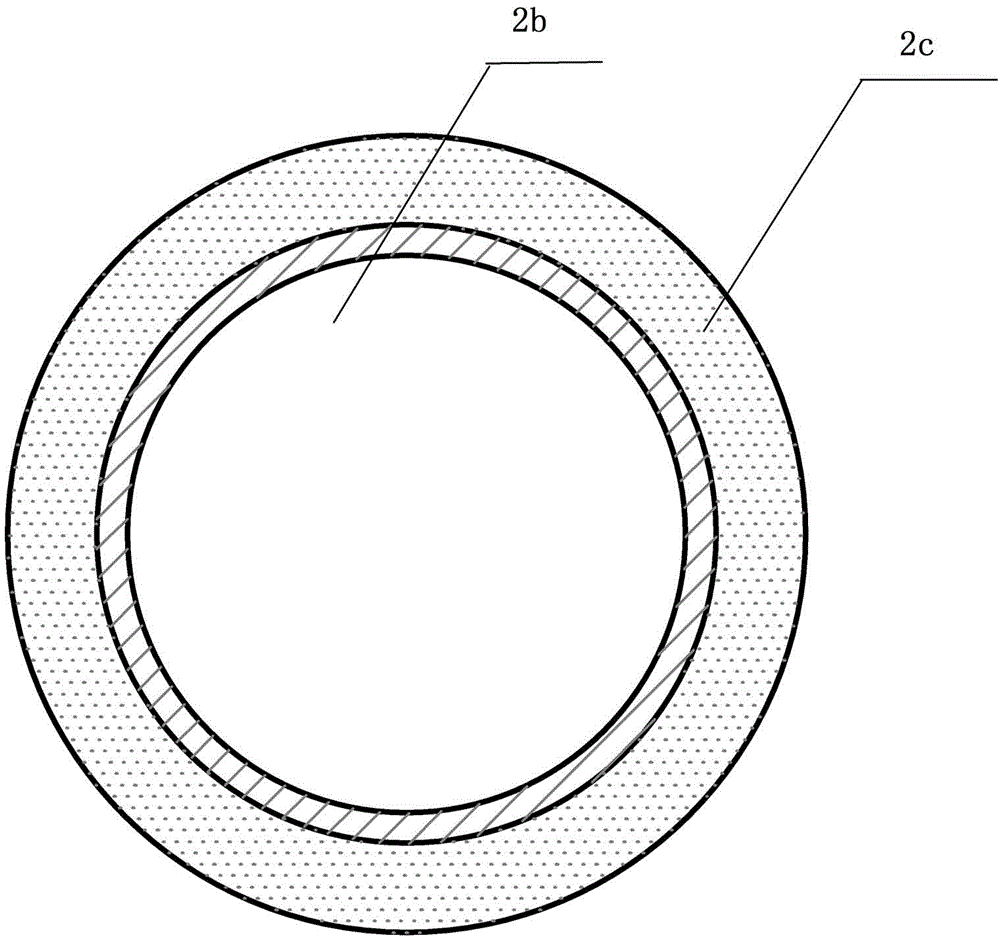

[0029] a. Bend the channel steel 1b into the shrinked shape of the lining trolley, and segment it in combination with 5 sections of the lining steel formwork trolley formwork. Each section is connected in a hinged manner, and a wire brush will be used as an angle grinder The angle grinder 1a is fixed to the channel steel 1b to form a group, and the distance between the angle grinder 1a is adjusted according to the size of the wire brush (angle grinder).

[0030] b. The automatic dust removal device 1 is made of two channel steels 1b fixed with several angle grinders 1a by bolts and welded side by side through steel bars, and the angle grinders 1a on the two channel steels are relatively staggered, and the automatic dust removal device It can be divided into sections in combination with the lining steel formwork trolley formwork, and the sections are connected by hinges.

[0031] d. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com