Last-stage front half section adjustable stator blade for axial-flow compressor and working method thereof

An axial flow compressor and stator blade technology, which is applied to the components of the pumping device for elastic fluids, mechanical equipment, machines/engines, etc., can solve the loss increase, loss, and can not guarantee the axial outlet of the final stage stator, etc. problems, to achieve the effect of broadening the operating range and improving the efficiency of the compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

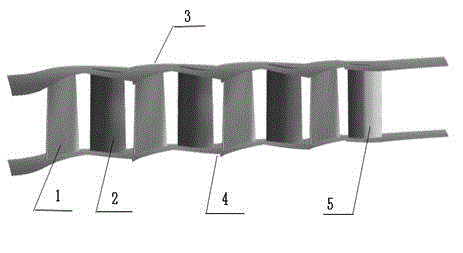

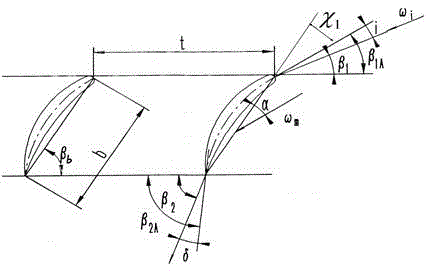

[0022] The following combination Figure 1 to Figure 7 Illustrate the implementation method of the adjustable stator vane in the front section of the present invention and the stator composed of it:

[0023] The blades of the final stator are obtained by the aerodynamic design method of the axial flow compressor, that is, the initial design, the flow design, the two-dimensional blade design and the three-dimensional blade design.

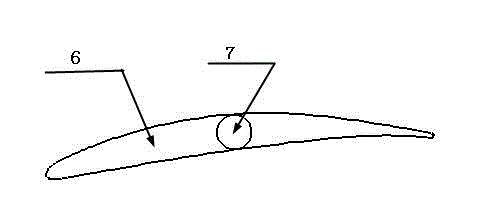

[0024] The specific structure of the final stator blade: the rotatable front blade 8 is fixed with the rotating shaft 9; the non-adjustable rear blade 10 is fixedly installed on the outer casing of the axial flow compressor ( Figure 5 ). When the operating condition of the axial flow compressor is adjusted, the rotation of the rotating shaft drives the deflection of the front blade to adapt to the change of the inlet airflow angle.

[0025] Example. Such as Figure 6 , rotate the front section of the stator, so that the front section of the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com