Energy-saving board pressing machine for bamboo boards

A technology of plate pressing machine and bamboo board, which is applied in the direction of veneer pressing machine, plywood pressing machine, wood compression, etc., can solve the problems of inaccurate control of oil quantity, sudden large and small pressure of plate pressing machine, uneven occlusion, etc. Achieve the effect of reducing scrap rate, reducing hydraulic oil consumption and saving hydraulic oil consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

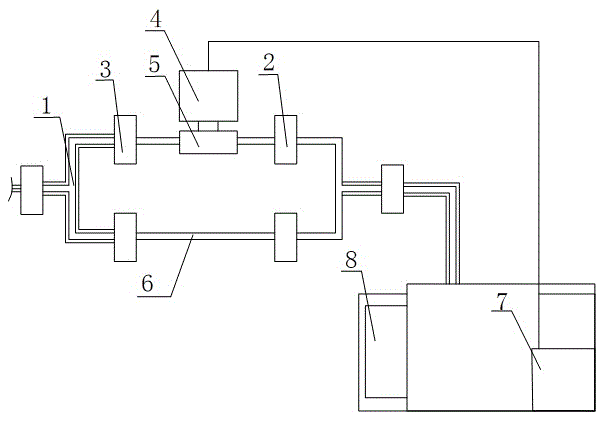

[0012] In order to deepen the understanding of the present invention, the following further describes the present invention with reference to the accompanying drawings and embodiments. The embodiments are only used to explain the present invention and do not limit the protection scope of the present invention.

[0013] Such as figure 1 As shown, the energy-saving press for bamboo board includes at least one hydraulic bypass 1 connected to the hydraulic oil circuit of the hydraulic press. Each hydraulic bypass 1 is provided with two hydraulic shunts 6, and each hydraulic shunt 6 is An overflow valve 2 and a filter 3 are connected in sequence, at least one of the hydraulic branches 6 is connected with a solenoid valve 4, and each solenoid valve 4 is connected to the control circuit of the press. In the plate press of the present invention, a solenoid valve 4 is placed on the hydraulic branch 6 of a hydraulic bypass on the hydraulic oil circuit, and the solenoid valve 4 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com