Heat preservation and sealing structure of anode baking furnace

A technology of anode roasting furnace and sealing structure, which is applied in the directions of engine sealing, furnace, furnace lining, etc., can solve the problems of increasing pressure and temperature control difficulty, uneven temperature distribution in the side fire channel, and reducing the service life of the furnace, so as to reduce the temperature The effect of uneven distribution, reducing control difficulty and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

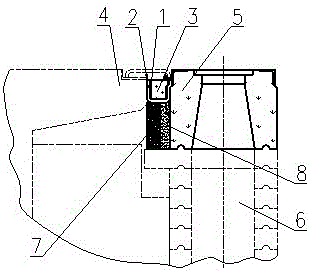

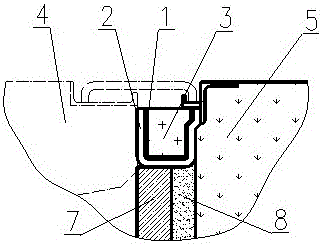

[0013] Referring to the accompanying drawings, a thermal insulation and sealing structure of an anode roaster includes a furnace shell 4, a furnace surface pouring block 5 and an insulating brick 7. The insulating brick 7 is arranged between the furnace shell 4 and the furnace surface pouring block 5, and the insulating brick 7. The horizontal height of the upper end surface is lower than the horizontal height of the upper end of the furnace shell 4 and the upper end of the furnace surface pouring block 5. The structure also includes a refractory fiber blanket 2, a partition plate 1 and a refractory castable 3. The refractory fiber blanket 2 is silicic acid Aluminum refractory fiber blanket, the thickness of which is 12mm, the thickness of the partition plate 1 is 0.35-0.5mm (preferably 0.35mm), the refractory fiber blanket 2 forms a 'U'-shaped groove structure and is laid on the furnace shell 4 and the furnace surface pouring block 5 Between the insulating brick 7, the bottom ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com