Electronics housing with integrated thermal dissipater

A radiator and housing technology, applied in the field of electronic housings of measuring transducers, can solve the problems of defects and high connection costs, and achieve the effect of reducing uneven temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

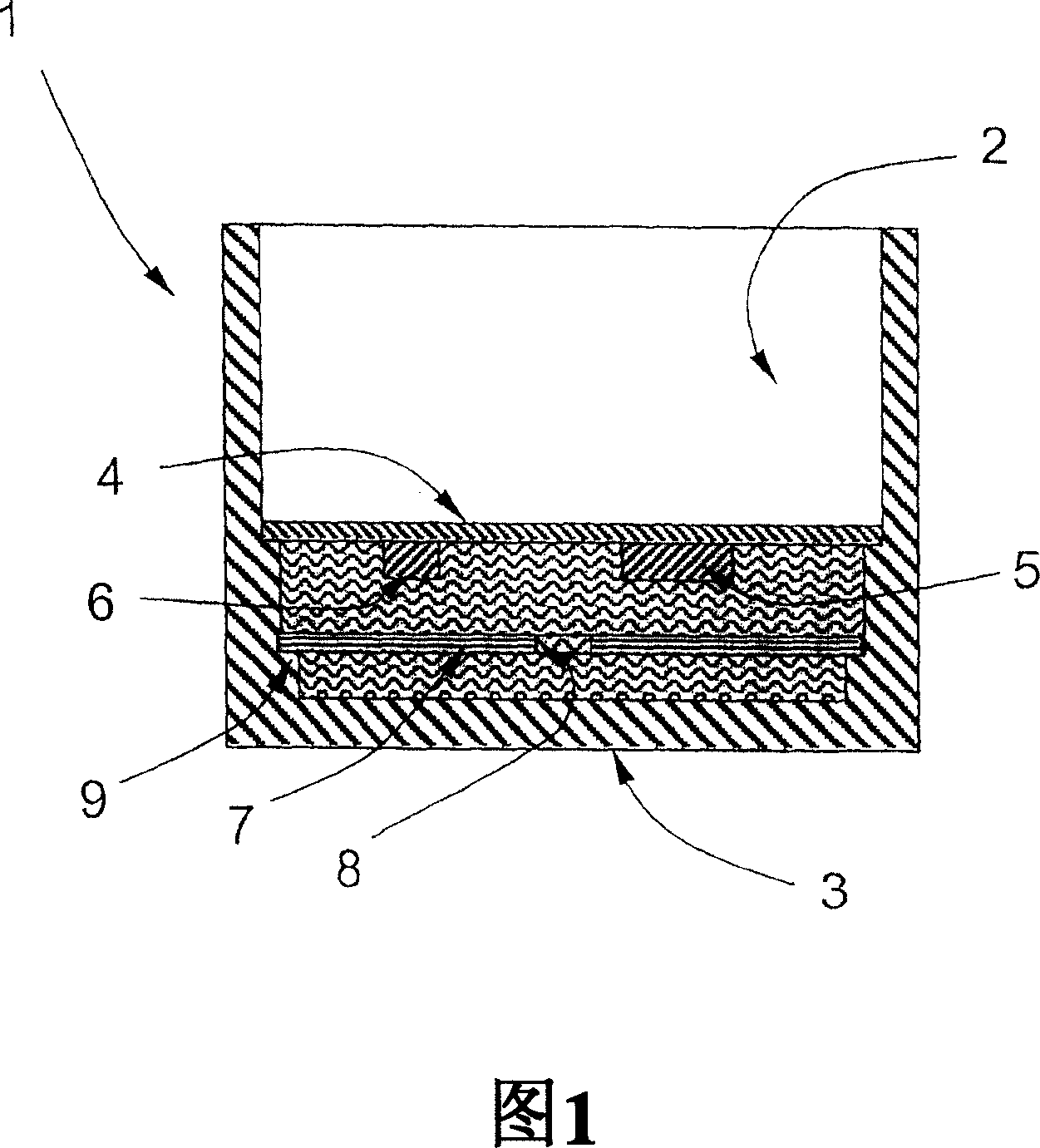

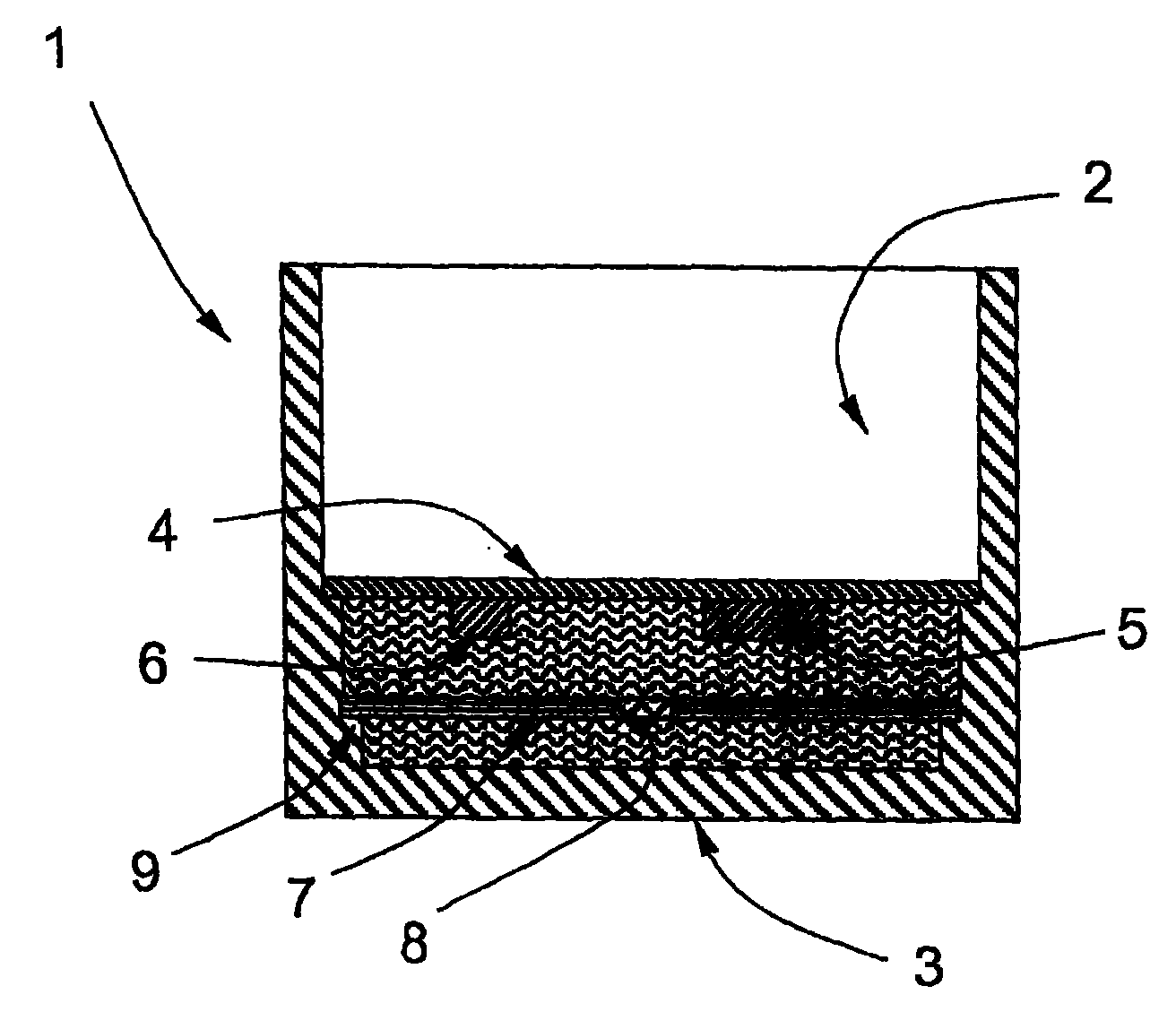

[0017] The measuring transducer housing 1 shown in FIG. 1 encloses an interior 2 on which a printed circuit board 4 is arranged parallel to the first wall 3 of the housing 1 . The first wall can be, for example, the end face of the cylindrical housing 1 . On the first surface of the circuit board 4 facing the first wall, electrical or electronic components 5, 6 are arranged, and in order to avoid overheating of the electronic components 5, 6, the heat generated during operation must be diverted away.

[0018] To this end, at least the interior 2 in the section between the circuit board 4 and the first wall 3 is filled with a filler 10 , preferably Silgel. A heat sink 7 is built into the filler, which is arranged substantially parallel to the circuit board 4 . The position of the heat sink 7 spaced apart from the circuit board and the first wall 3 is defined in structural form by a stop 9 on which the edge of the heat sink is placed.

[0019] The heat sink 7 is preferably a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com