A cross-tube heat exchanger and a pulse tube refrigerator with the heat exchanger

A technology of tubular heat exchangers and thin tubes, which is applied in the direction of refrigerators, indirect heat exchangers, heat exchanger types, etc., can solve the problem of restricting the development of high-power pulse tube refrigerators and the uneven inlet temperature of the hot end of the regenerator , Uneven temperature distribution at the inlet and outlet, etc., to alleviate the uneven temperature distribution, improve the uneven temperature distribution, and the effect of simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

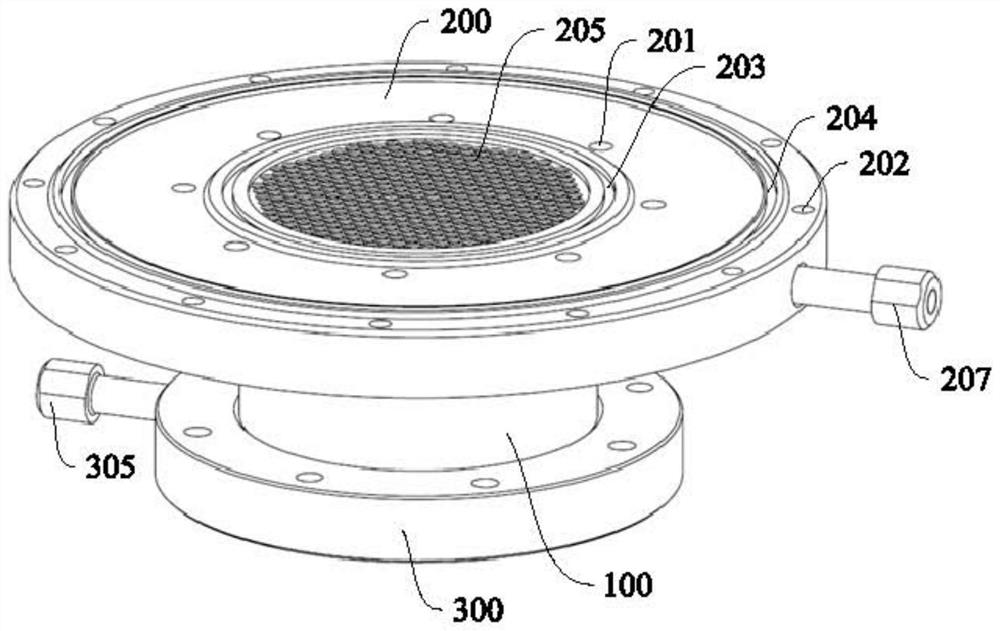

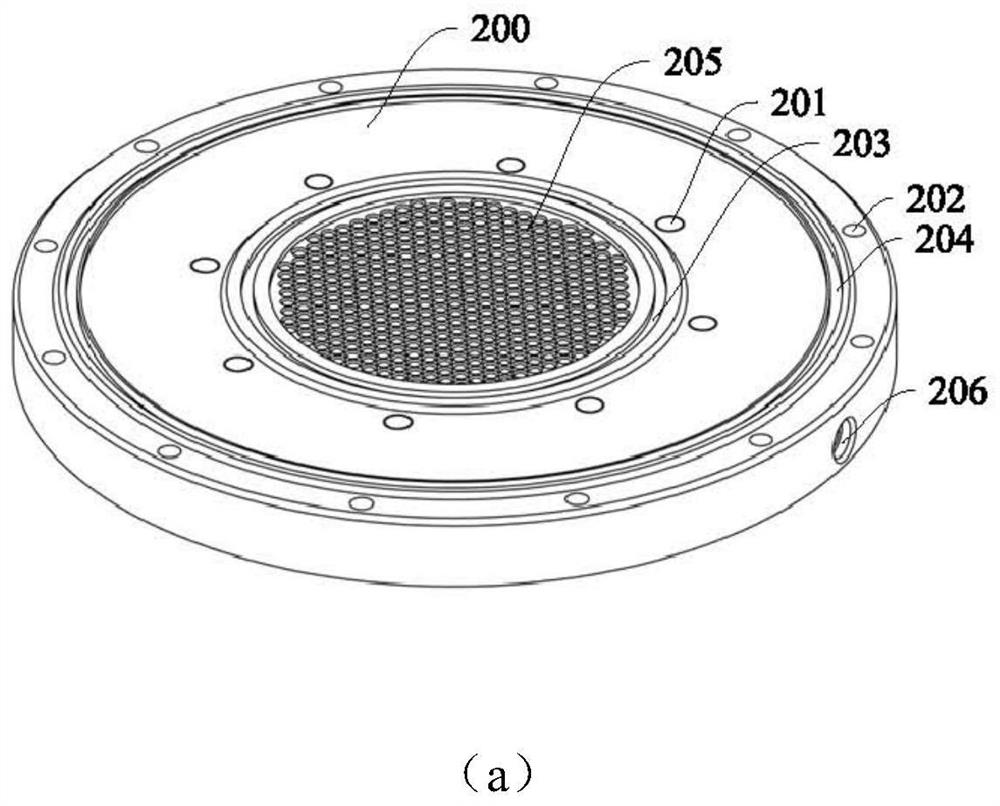

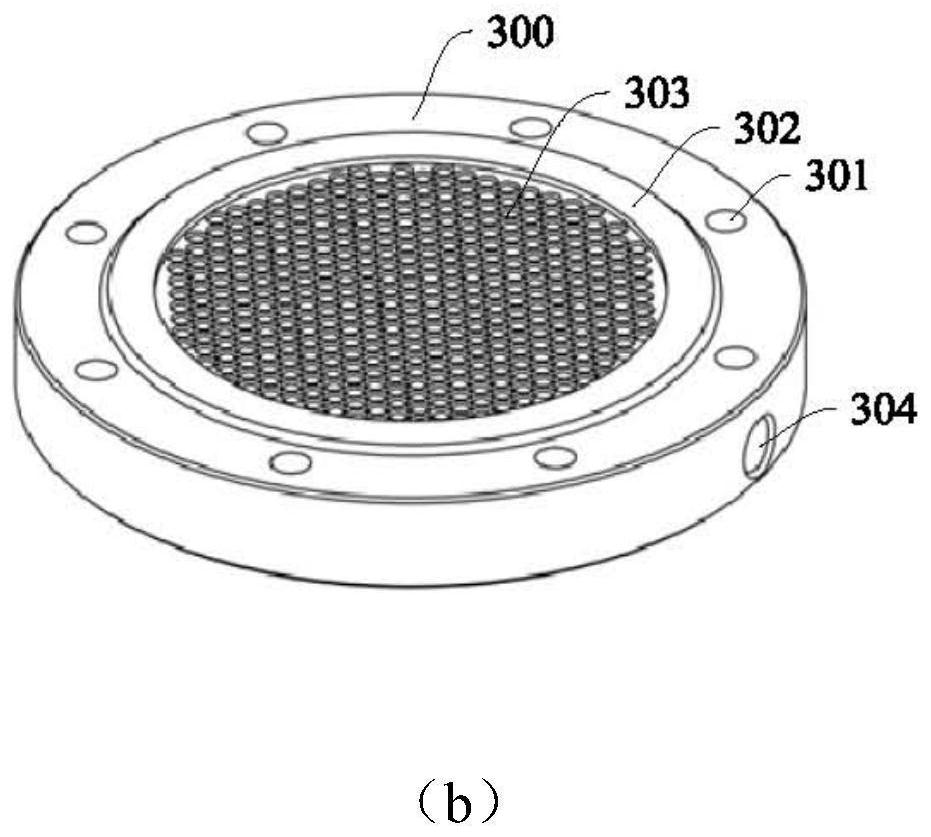

[0035] see Figure 1 to Figure 4 , the cross-tube heat exchanger in this embodiment includes a cylinder body 100 and an upper flange 200 and a lower flange 300 that are hermetically installed at both ends of the cylinder body 100 .

[0036] The upper flange 200 is provided with circumferentially arranged threaded holes 201 and 202 for connecting the next stage component (regenerator) and the vacuum cover. A sealing ring groove 203 and a sealing ring groove 204 for sealing the next-stage components are respectively provided adjacent to the threaded hole circumferential direction. An upper mounting plate 205 is arranged in the middle of the upper flange 200, and a plurality of mounting holes for thin heat exchange tubes are regularly opened. The side of the upper flange 200 has an outlet channel 206 connected to the middle through hole, and an outlet pipe 207 is sealed inside it.

[0037] The lower flange 300 is provided with circumferentially arranged threaded holes 301 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com