Automatic argon blowing connector device

A joint device and automatic technology, applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc., can solve the problem that the male end of the joint is not easy to disassemble and replace, so as to save replacement and installation time, improve production efficiency, and reduce replacement effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

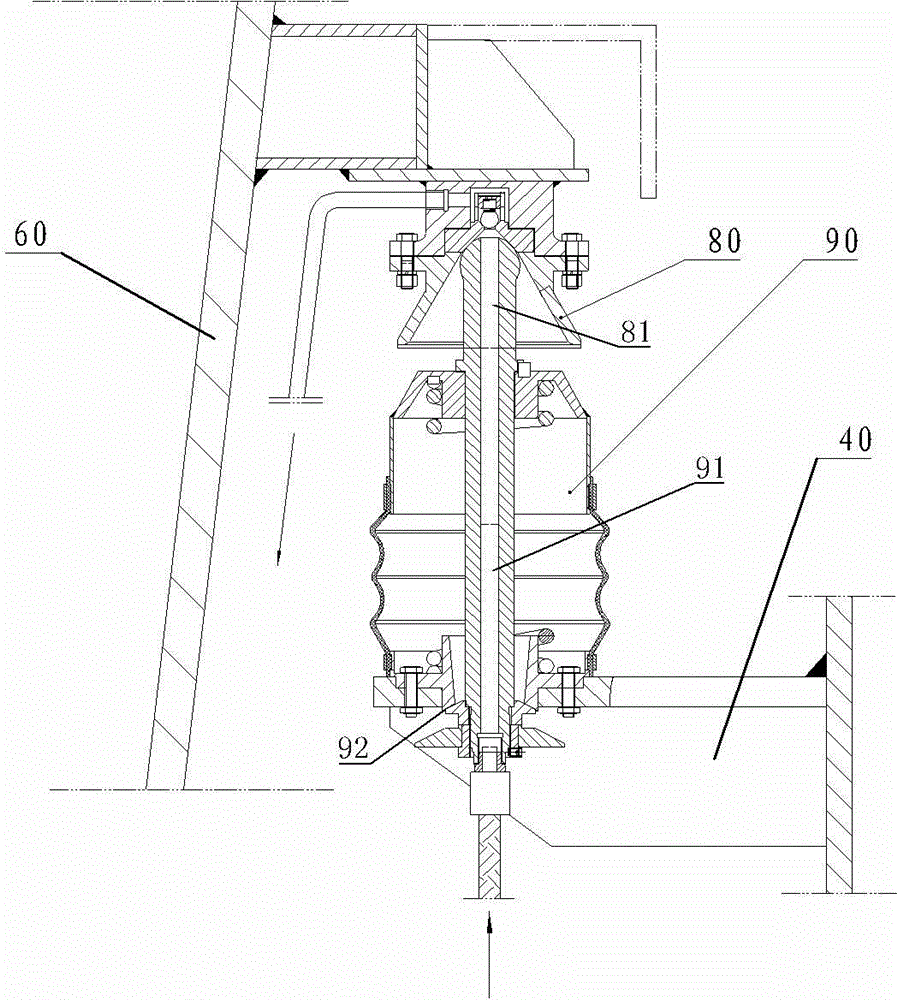

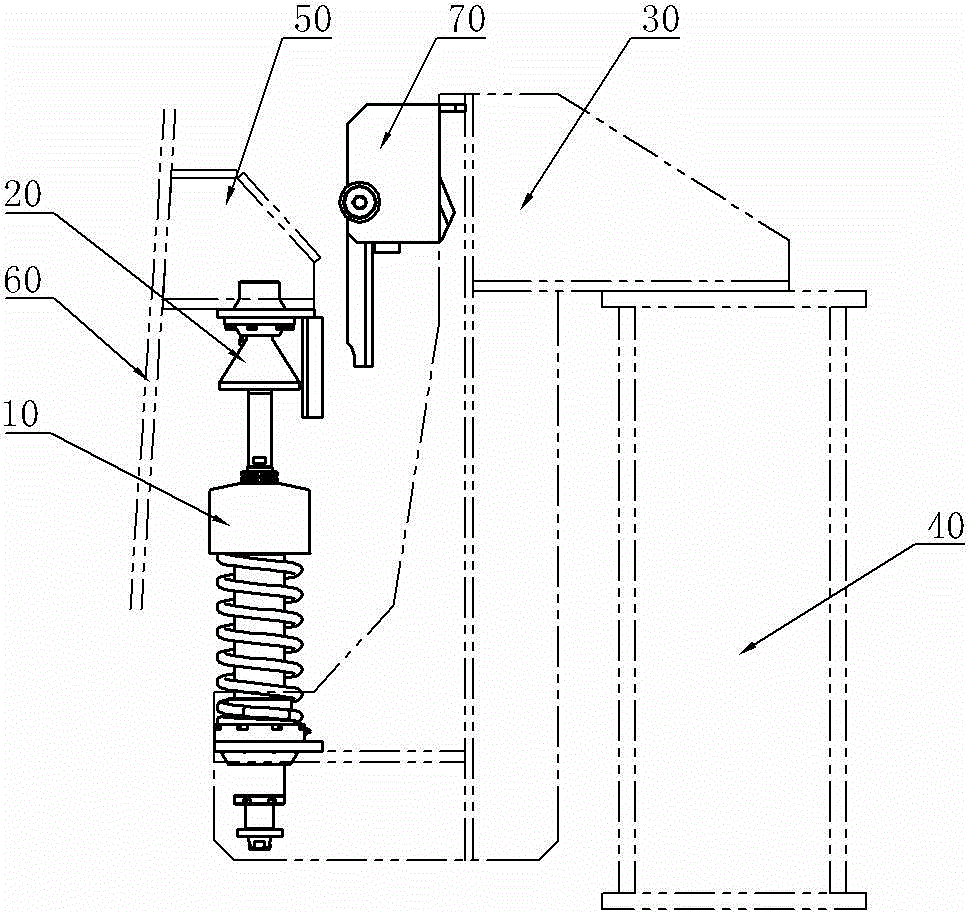

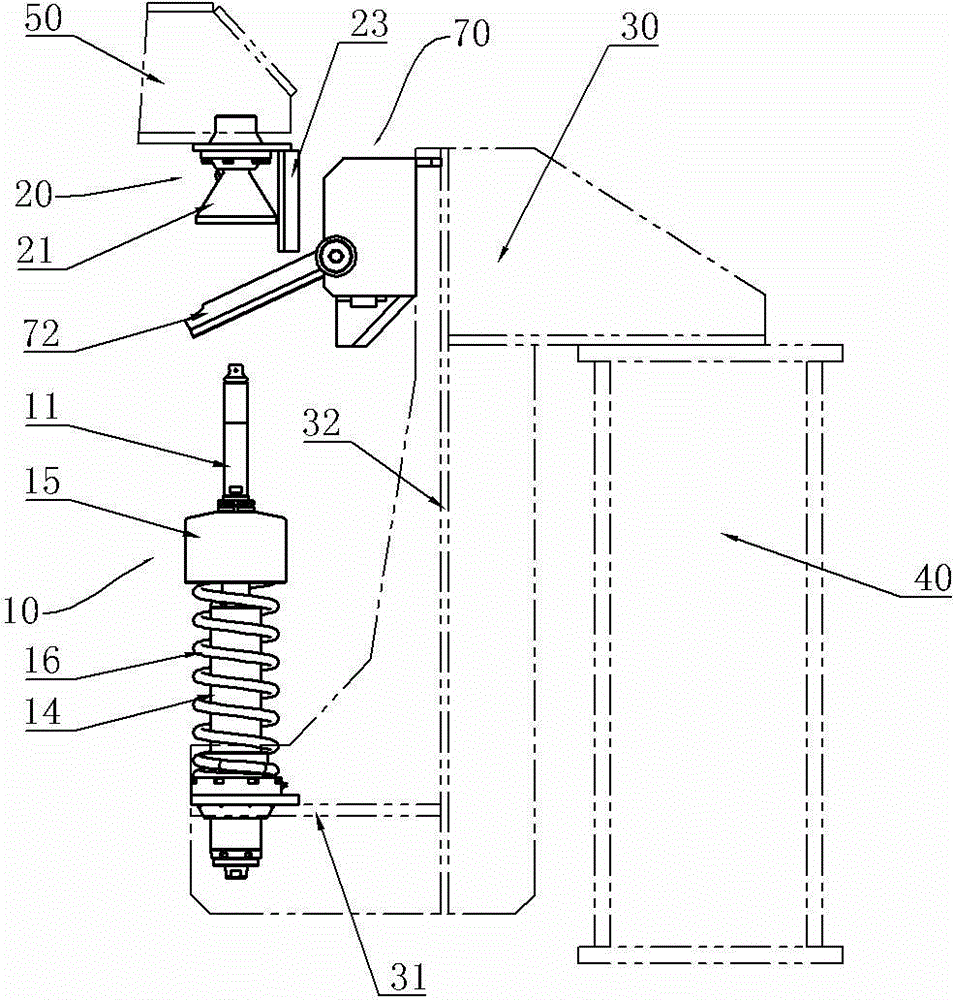

[0028] See figure 2 and image 3 , the automatic argon blowing joint device of the present invention includes a joint male end 10 and a joint female end 20, the joint male end 10 is fixedly installed on the transfer device 40 through the male end mounting frame 30, and the joint female end 20 is installed on the On the tank wall 60 of the steel ladle; see Figure 4 , the male end of the joint 10 includes a male end joint body 11, and the male end joint body 11 is provided with an axially penetrated air duct 12, and the male end joint body 11 includes a coaxial detachable top joint body 111, a joint main body 112, and a bottom The joint body 113, the two ends of the joint body 112 are respectively detachably connected with the top joint body 111 and the bottom joint body 112, and the top joint body 111, the joint main body 112, and the bottom joint body 113 are respectively provided with ventilation pipes 121, 122, 123, And the vent pipes 121, 122, 123 of the top joint body,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com