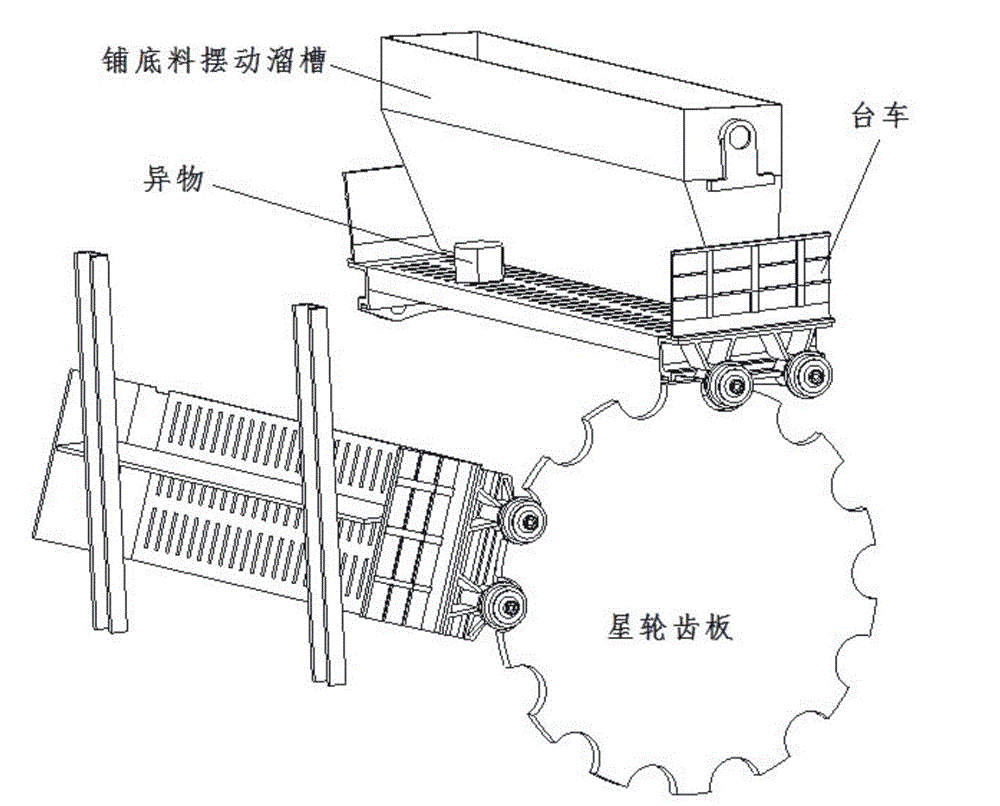

Trolley grate surface foreign matter detecting device of sintering machine

A foreign matter detection and detection device technology is applied in the field of metallurgical sintering, which can solve the problems of topping the swing chute of the bedding material and the breaking of the ventilation rod device, so as to achieve the effects of ensuring stable and forward running, preventing slippage and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

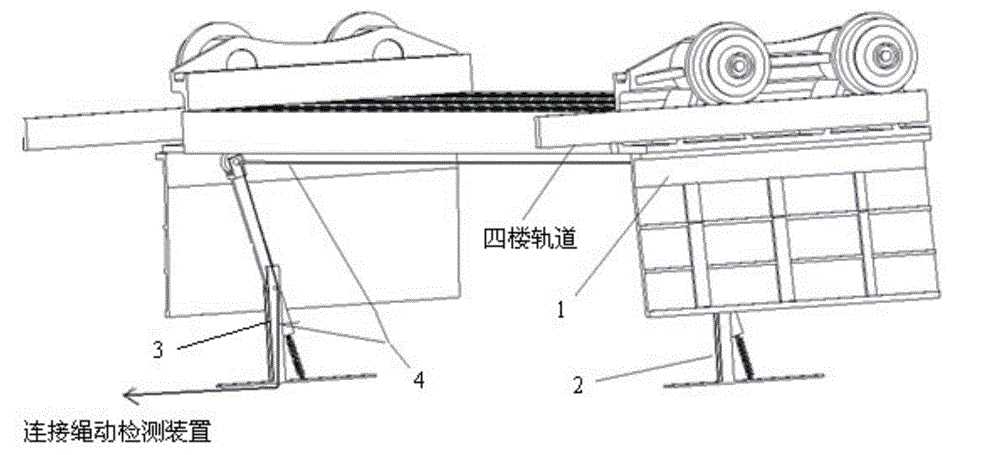

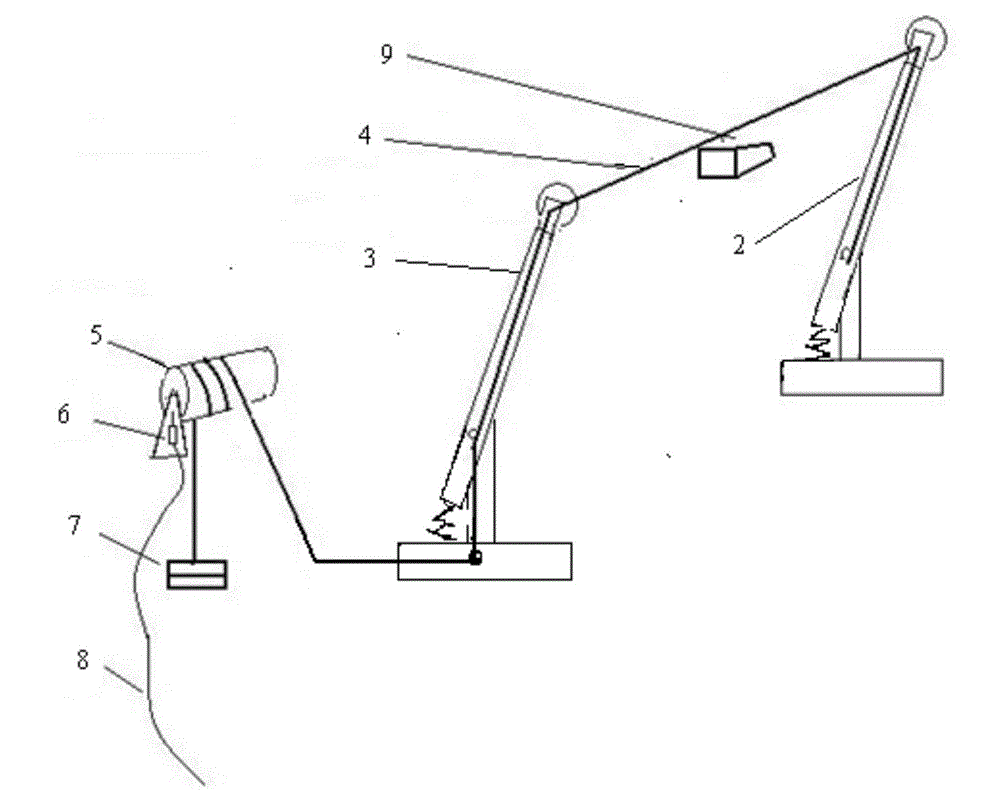

[0031] Attached below Figure 1-6 The present invention is described in further detail.

[0032] Figure 1-6 Among them, 1 is the trolley, 2 is the first tension support arm, 3 is the second tension support arm, 4 is the detection rope, 5 is the roller, 6 is the limit switch, 7 is the counterweight, 8 is the signal cable, 9 is the foreign matter bonded on the trolley bar surface, 10 is a roller, 11 is a rope ring, 12 is a support arm support, 13 is a spring, 14 is a swing connecting rod, 15 is a roller support, and 16 is a block.

[0033] The detection device of the present invention includes a first tension support arm, a second tension support arm and a rope motion detection device, the first tension support arm and the second tension support arm are respectively arranged on both sides of the trolley, the first Both the tension support arm and the second tension support arm include a support arm bracket and a swing link, one end of the swing link is connected with a roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com