Lining paper conveying device for thin cigarette packaging machine

A conveying device and lining paper technology, applied in the direction of packaging material feeding device, packaging, transportation packaging, etc., can solve the problem of prolonging the maintenance cycle of the lining paper suction chamber, unqualified packaging quality of cigarette packs, and easy blockage of the suction hole and other problems, to achieve the effect of reliable transportation and adsorption of inner lining paper, reduce the number of cigarette packs and production costs, and facilitate smooth transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

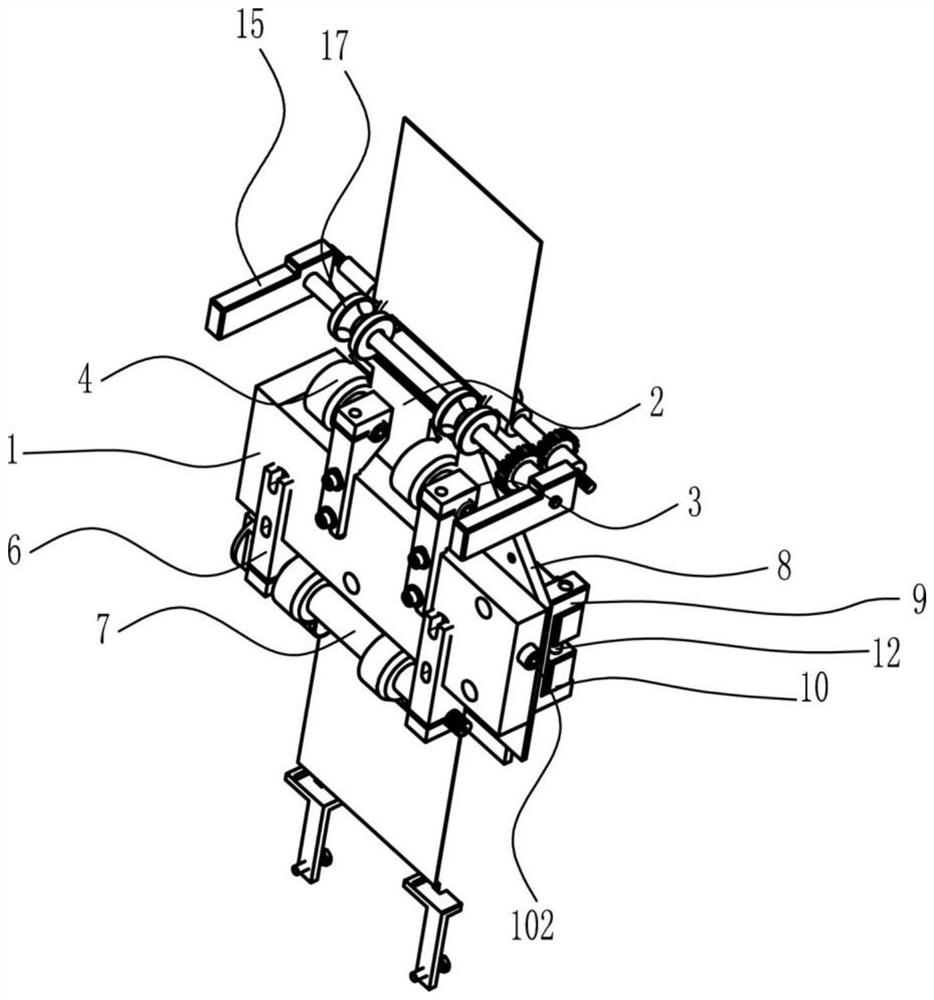

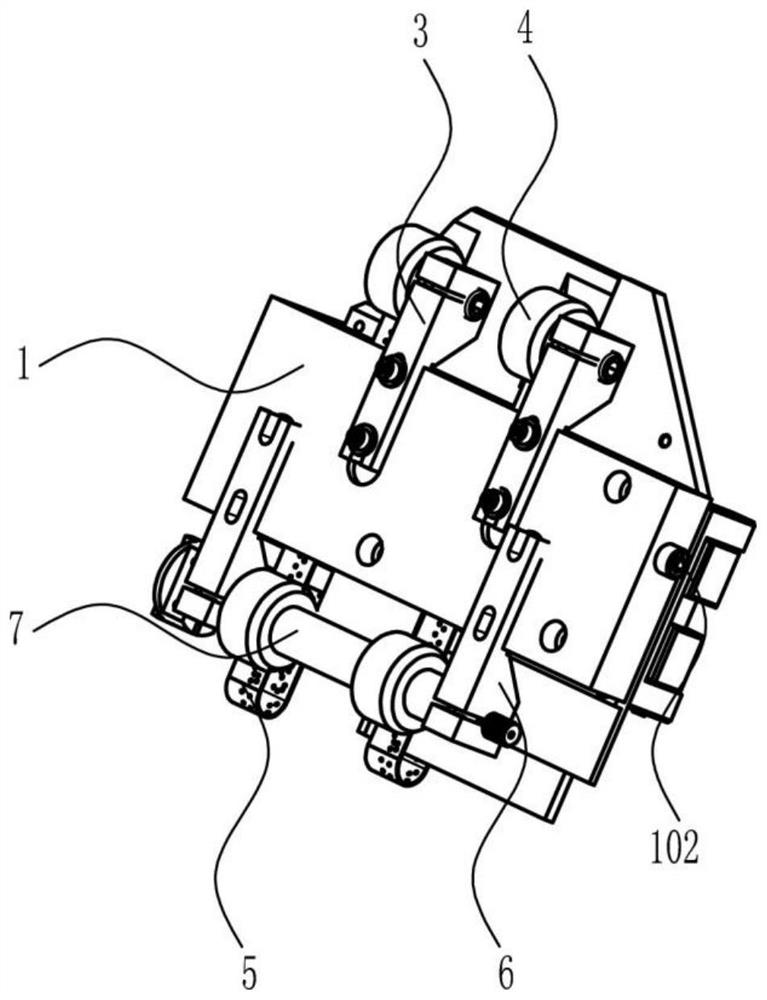

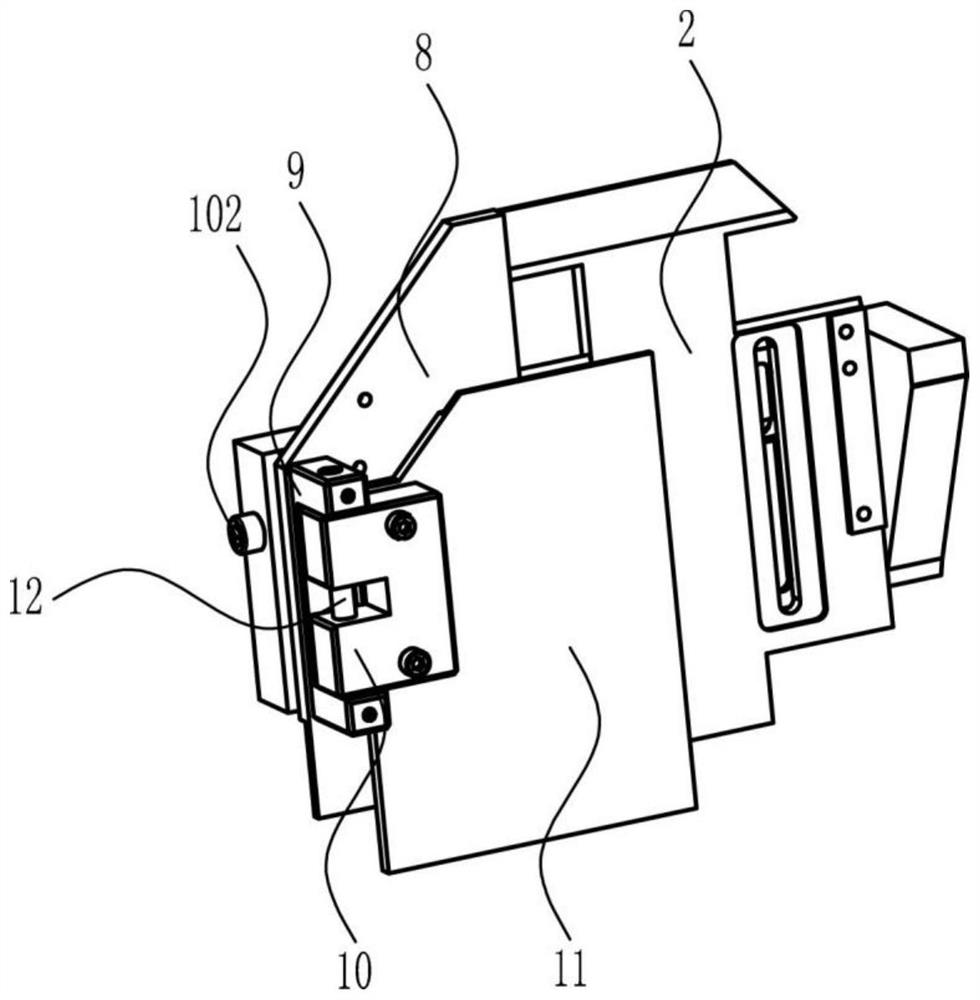

[0037] A lining paper conveying device for thin cigarette packaging machine, such as Figure 1 to Figure 8 shown, figure 1 It is the overall appearance structure diagram of the present invention, figure 2 It is the structural diagram of the rear side view of the appearance of the suction part of the lining paper of the present invention, image 3 It is the main side view structure diagram of the appearance of the suction part of the lining paper of the present invention, Figure 4 It is the appearance structure diagram of the indentation part of the lining paper of the present invention, Figure 5 It is the appearance structure diagram of the positioning part of the lining paper of the present invention, Image 6 It is a schematic diagram of the front axonometric structure of the suction base of the suction part of the lining paper of the present invention, Figure 7 It is a schematic diagram of the axonometric structure of the rear side of the suction base of the suction...

Embodiment 2

[0045] A lining paper conveying device for thin cigarette packaging machine, such as Figure 1 to Figure 9 shown, figure 1 It is the overall appearance structure diagram of the present invention, figure 2 It is the structural diagram of the rear side view of the appearance of the suction part of the lining paper of the present invention, image 3 It is the main side view structure diagram of the appearance of the suction part of the lining paper of the present invention, Figure 4 It is the appearance structure diagram of the indentation part of the lining paper of the present invention, Figure 5 It is the appearance structure diagram of the positioning part of the lining paper of the present invention, Image 6 It is a schematic diagram of the front axonometric structure of the suction base of the suction part of the lining paper of the present invention, Figure 7 It is a schematic diagram of the axonometric structure of the rear side of the suction base of the suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com