Petroleum drill pipe joint detection device and method

A technology for oil drill pipe joints and testing equipment, applied in the field of petroleum machinery, can solve the problems of high measurement skill requirements, fatigue measurement errors, low measurement efficiency, etc., and achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, the specific implementation, structure, Features and their functions are described in detail below.

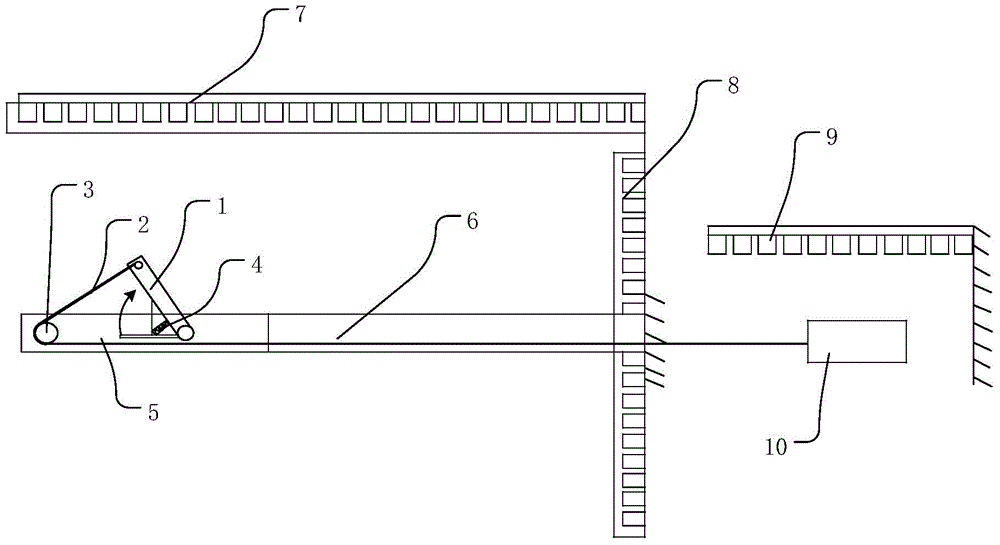

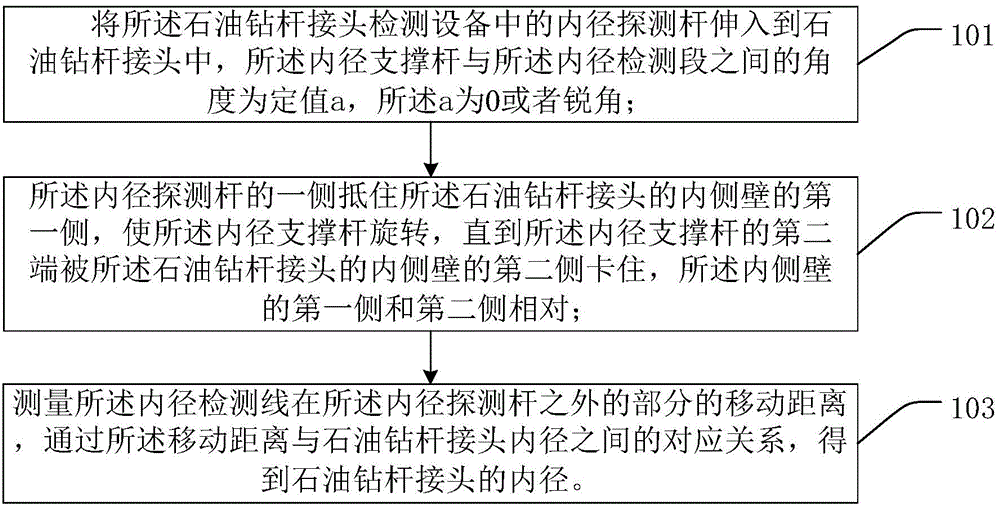

[0020] Such as figure 1 As shown, the embodiment of the present invention provides a kind of oil drill pipe detection equipment, including: a detection device, the detection device includes: a hollow inner diameter detection rod 6, the inner diameter detection rod 6 has an inner diameter detection section 5, and the inner diameter detection rod 6 has a An inner diameter support rod 1 is provided; the inner diameter detection section 5 includes a first end and a second end, the inner diameter support rod 1 includes a first end and a second end, the inner diameter support rod 1 and the inner diameter detection rod 6 are located on the same plane, and the inner diameter support rod 1 The first end of the inner diameter detection se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com