Automobile wire harness test device

A technology for testing equipment and automotive wiring harnesses. It is applied in the direction of measuring electricity, measuring devices, and measuring electrical variables. It can solve the problems of wasting test preparation time, consuming time, and reducing the actual efficiency of testing, and achieve the effect of improving test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

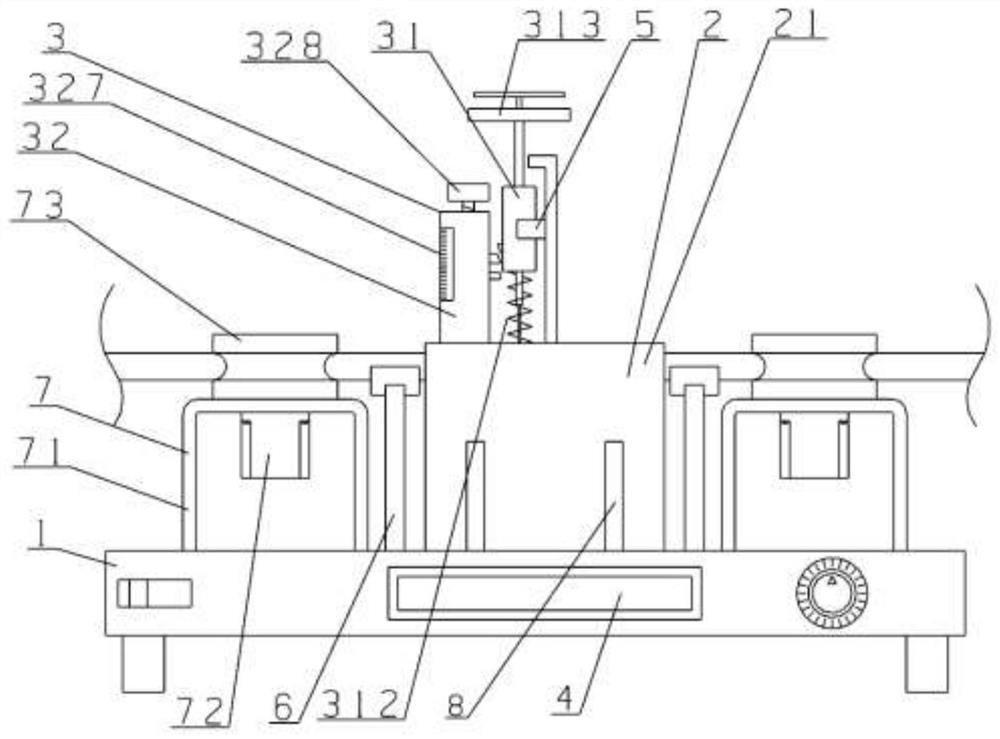

[0027] In one example, see Figure 1 to Figure 5 , a kind of automobile wiring harness testing equipment, comprises abutment 1, also comprises:

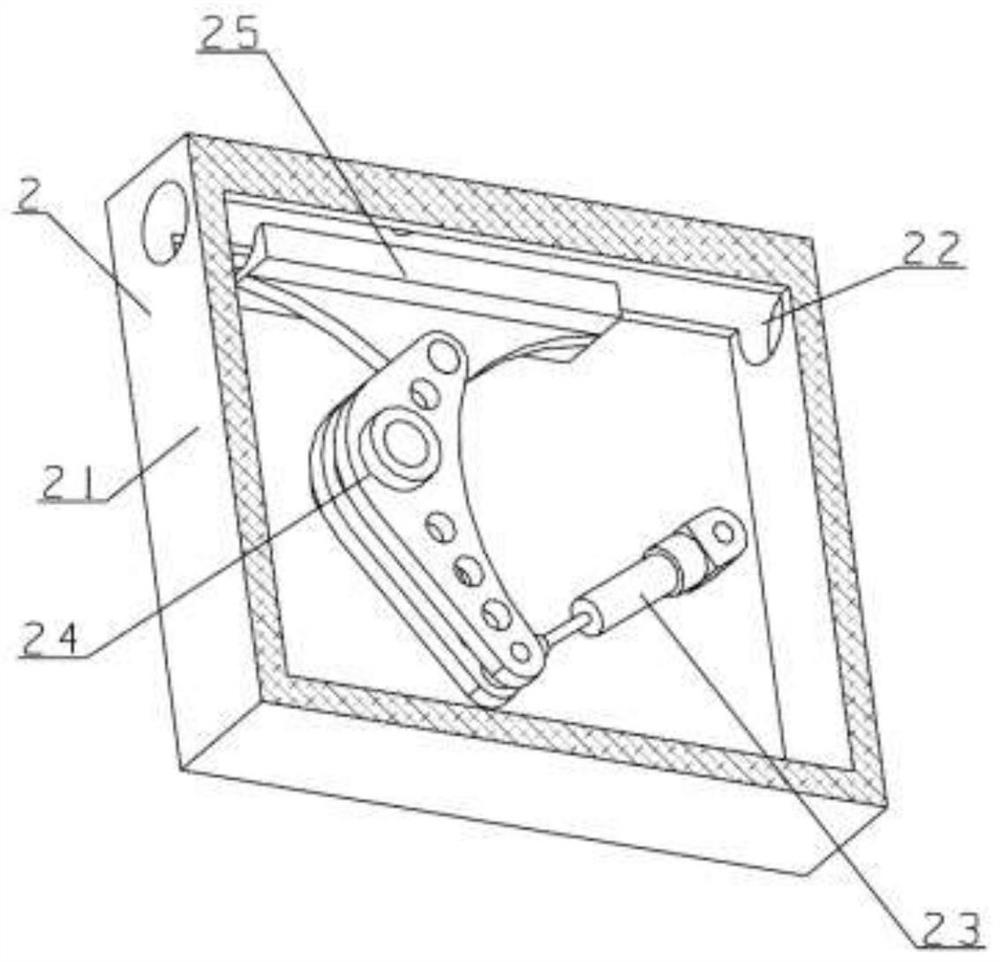

[0028] A clamping structure 2, the clamping structure 2 is fixedly installed on the base 1, and the clamping structure 2 is used to limit the movement of the wire harness;

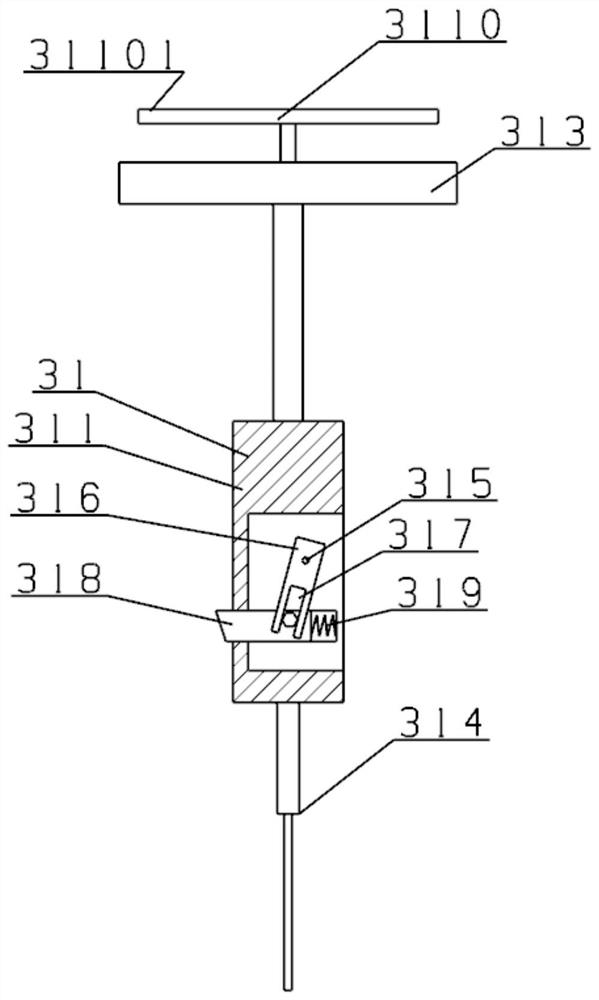

[0029] The puncture detection structure 3, the puncture detection structure 3 includes a lifting puncture structure 31 and a limit structure 32, the limit structure 32 includes a fixed seat 321 fixedly installed on one side of the clamping structure 2, and the fixed seat 321 Rotationally connected with a screw rod 322, one end of the screw rod 322 is fixedly equipped with a hand wheel 328, and the other end of the screw rod 322 is rotatably connected with a bearing seat installed in the fixed seat 321, and a bearing seat for connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com