A loading device for precise control of rivet pre-tightening force in riveted structure

A riveting structure and precise control technology, applied in the field of testing, can solve problems such as the inability to effectively measure the pre-tightening force of riveting fretting fatigue tests, the inability to understand and grasp the pre-tightening force in time, and the inability to obtain test data and results, etc., to achieve Accurate data recording and analysis, reliable principle and uniform loading force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

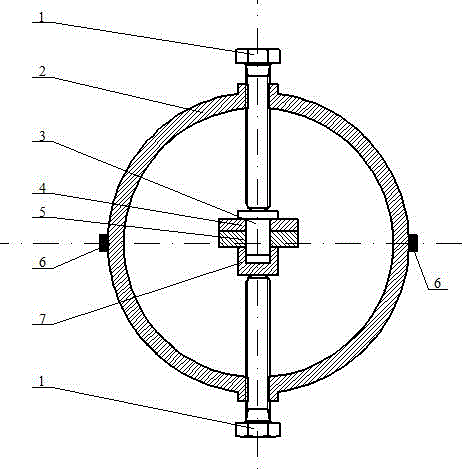

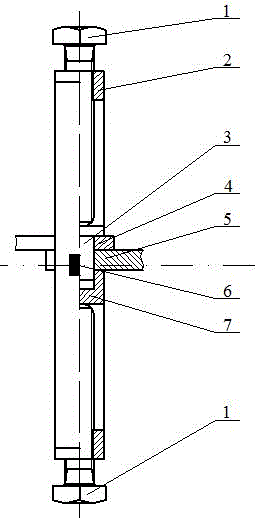

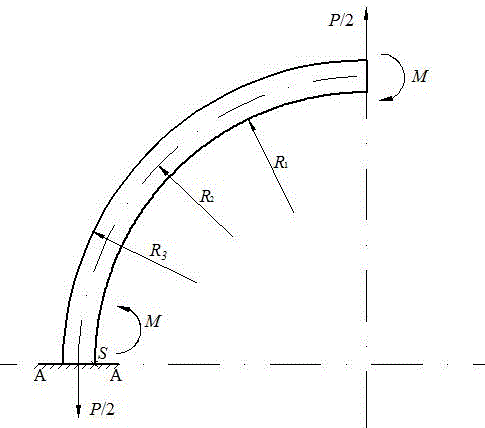

[0010] The device includes a ring clamp 2 and two bolts 1 on the same axis. The end of the bolt 1 needs to apply a contact load to the pressure block 7, and to make the contact pressure applied by the pressure block 7 uniform, the end of the bolt is designed to be hemispherical. When the load is applied, the hemispherical end contacts with the center of the upper surface of the briquetting block 7 to ensure equal contact pressure at both ends of the briquetting block 7 .

[0011] When installing, first place the pressure block 7 horizontally on the contact between the upper plate 4, the lower plate 5 and the pin 3, so that the centerline of the bolt 1 and the centerline of the pin 3 are on the same straight line, so that the load can be applied evenly on the Then tighten the bolts 1 at the two ends of the ring clamp 2. The pin 3 and the pressing block 7 jointly simulate the riveted rivet. Connect the strain gauges 6 attached to the two ends of the ring fixture 2 to the stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com