A sealing device for high-speed rotary impeller machinery

A technology of sealing device and impeller machinery, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problems of increased leakage, large difference in sealing performance, enhanced axial vibration of the rotating shaft, etc. Oblique and axial linearity are good, and the effect of axial vibration compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

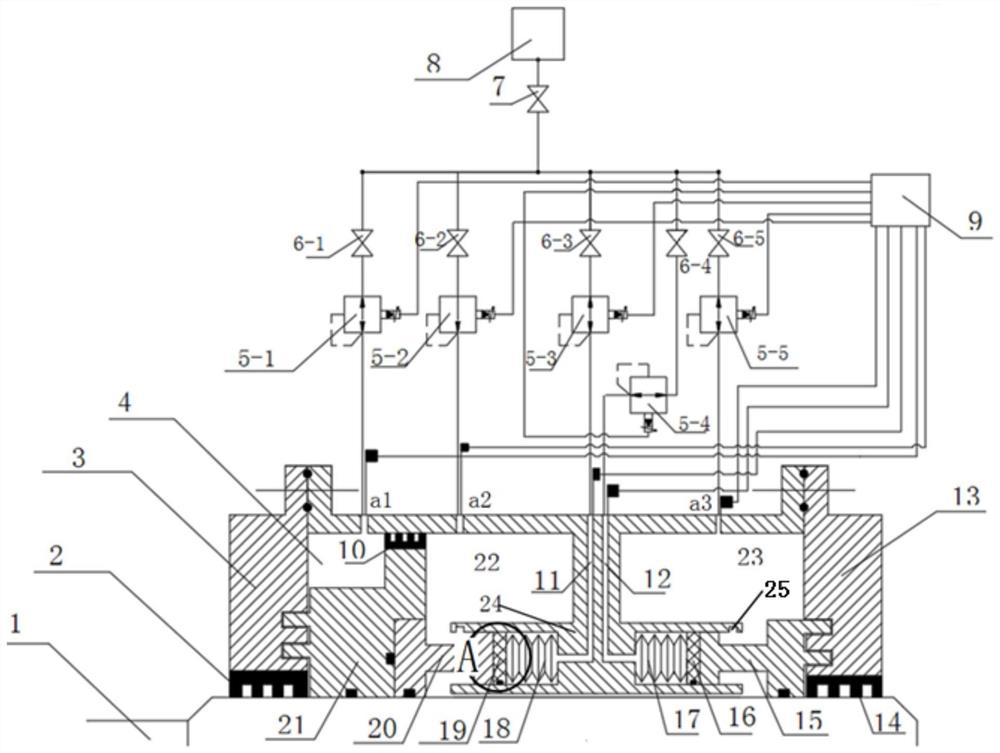

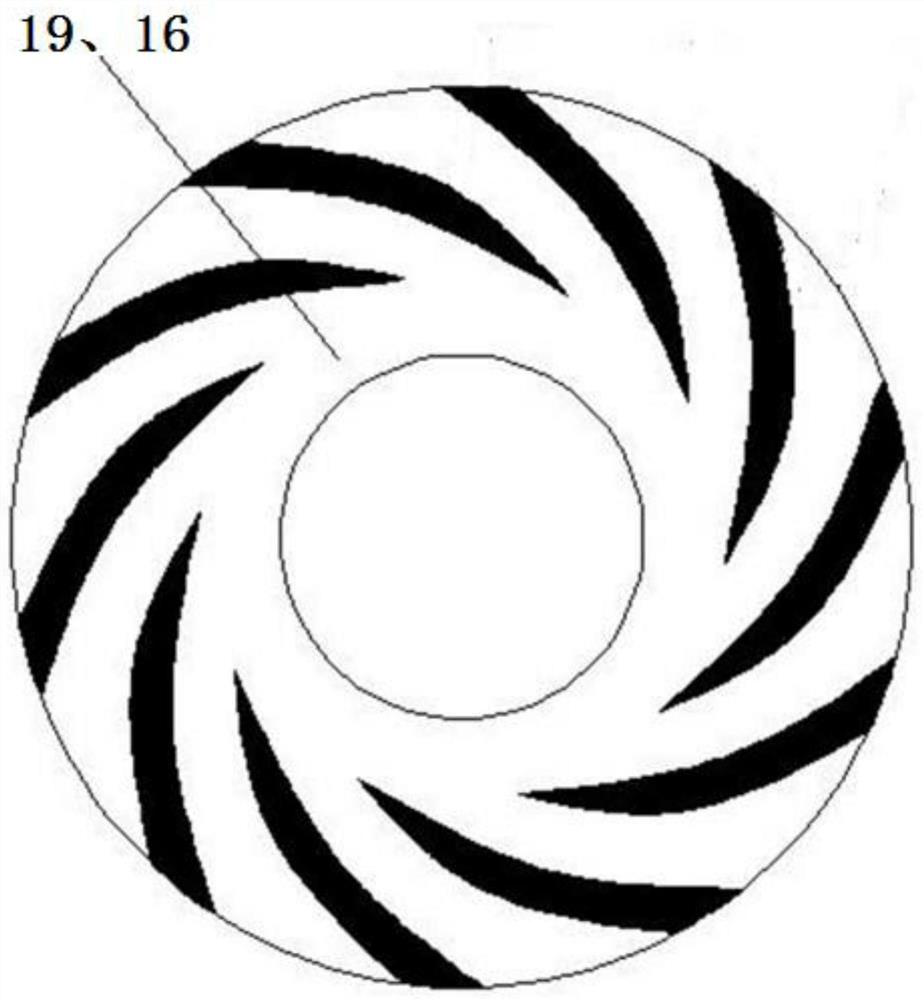

[0027]The present invention provides a sealing device for high-speed rotating impeller machinery. The sealing device for high-speed rotating impeller machinery is a multi-stage combined sealing structure formed by a double-end hydrodynamic mechanical seal and a labyrinth rotary seal; the sealing device has a sealing control system, and the sealing control system is the The sealing device provides a certain pressure of sealing protective gas, and monitors and controls the working conditions of the sealing protective gas and the sealing device in real time.

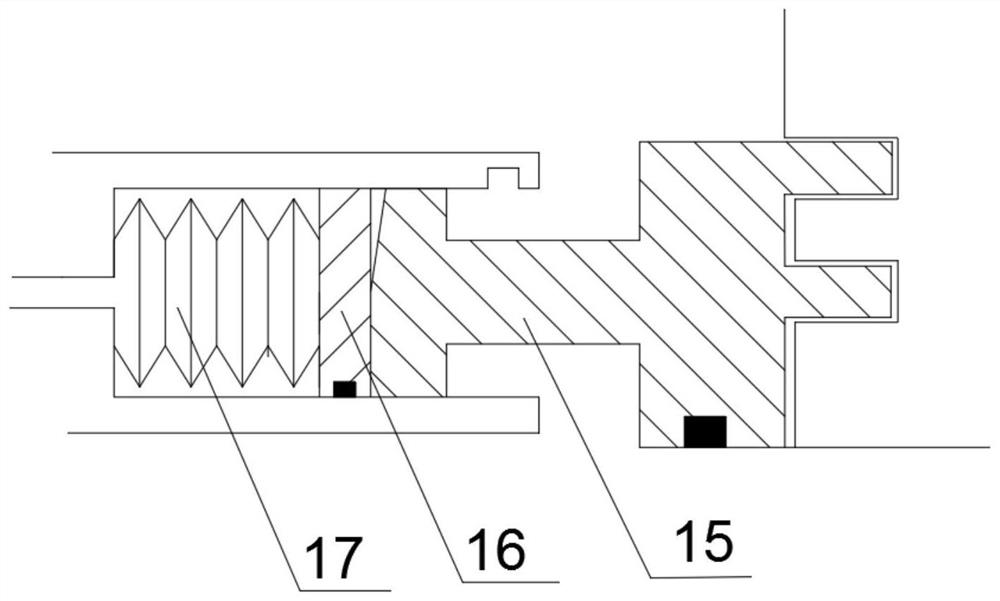

[0028] The sealing device has a rotating shaft 1, a left end cover 3 and a right end cover 13, and two ends are respectively connected with the left end cover 3 and the right end cover 13. The circumferential shell is fixedly connected; the left end cover 3 and the right end cover 13 are respectively provided with a first labyrinth seal The device 2 and the second labyrinth seal device 14, the first labyrinth seal device 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com