Double-wheel opposed rotor engine

A rotary engine and engine technology, applied to engine components, combustion engines, machines/engines, etc., can solve problems such as energy consumption, energy exhaustion, exhaust emissions, etc., to achieve increased torque, low fuel composition, and fuel saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

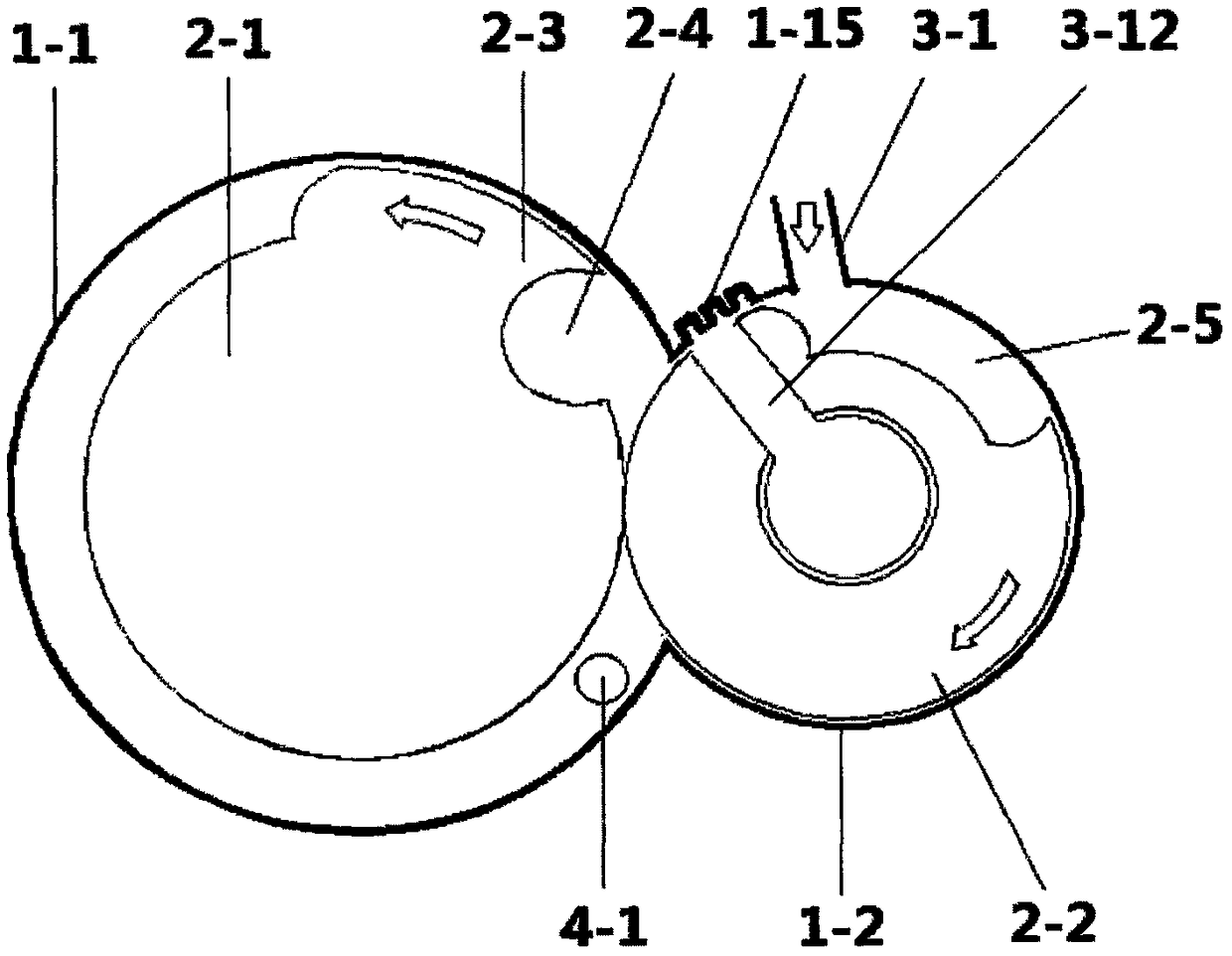

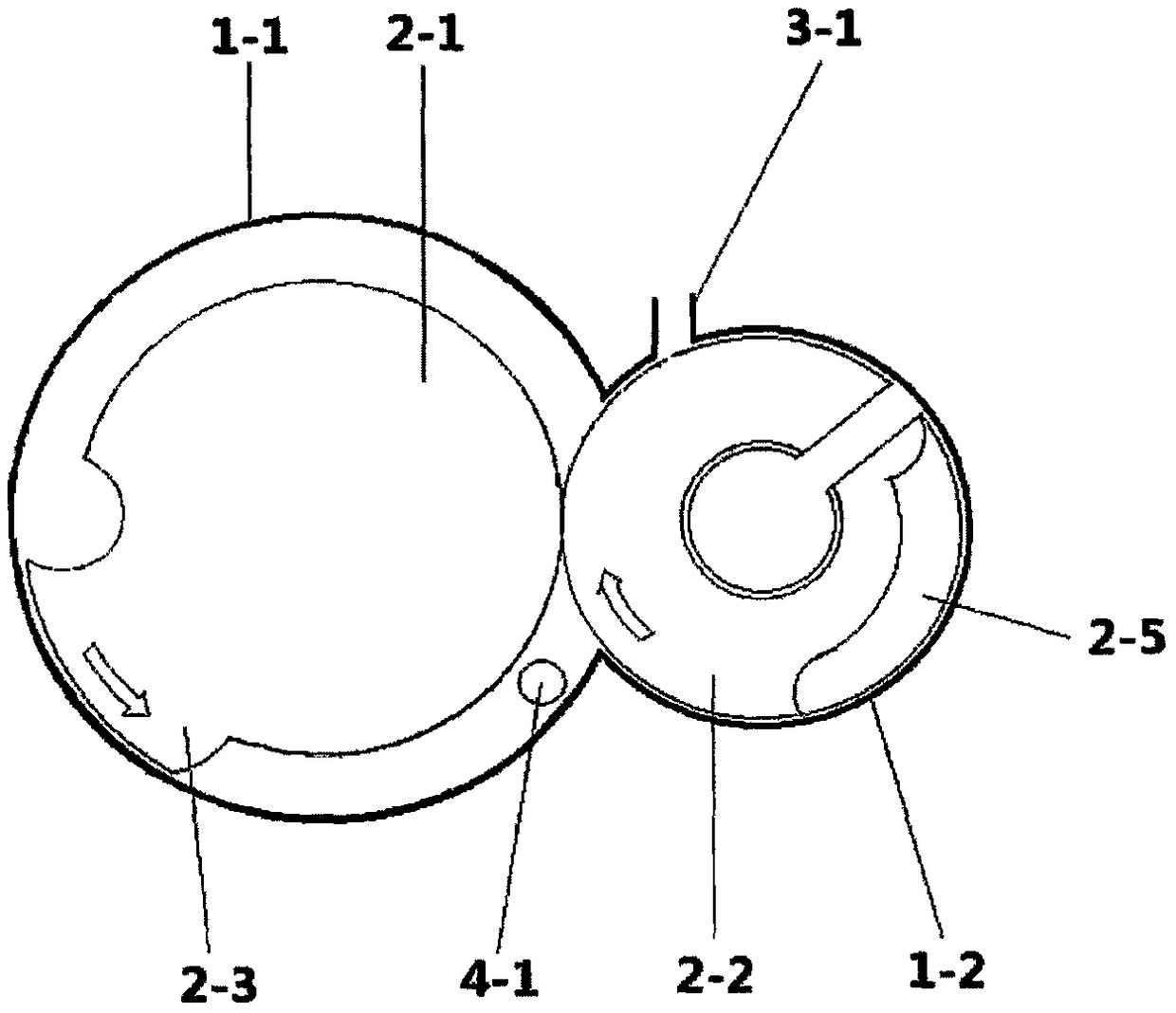

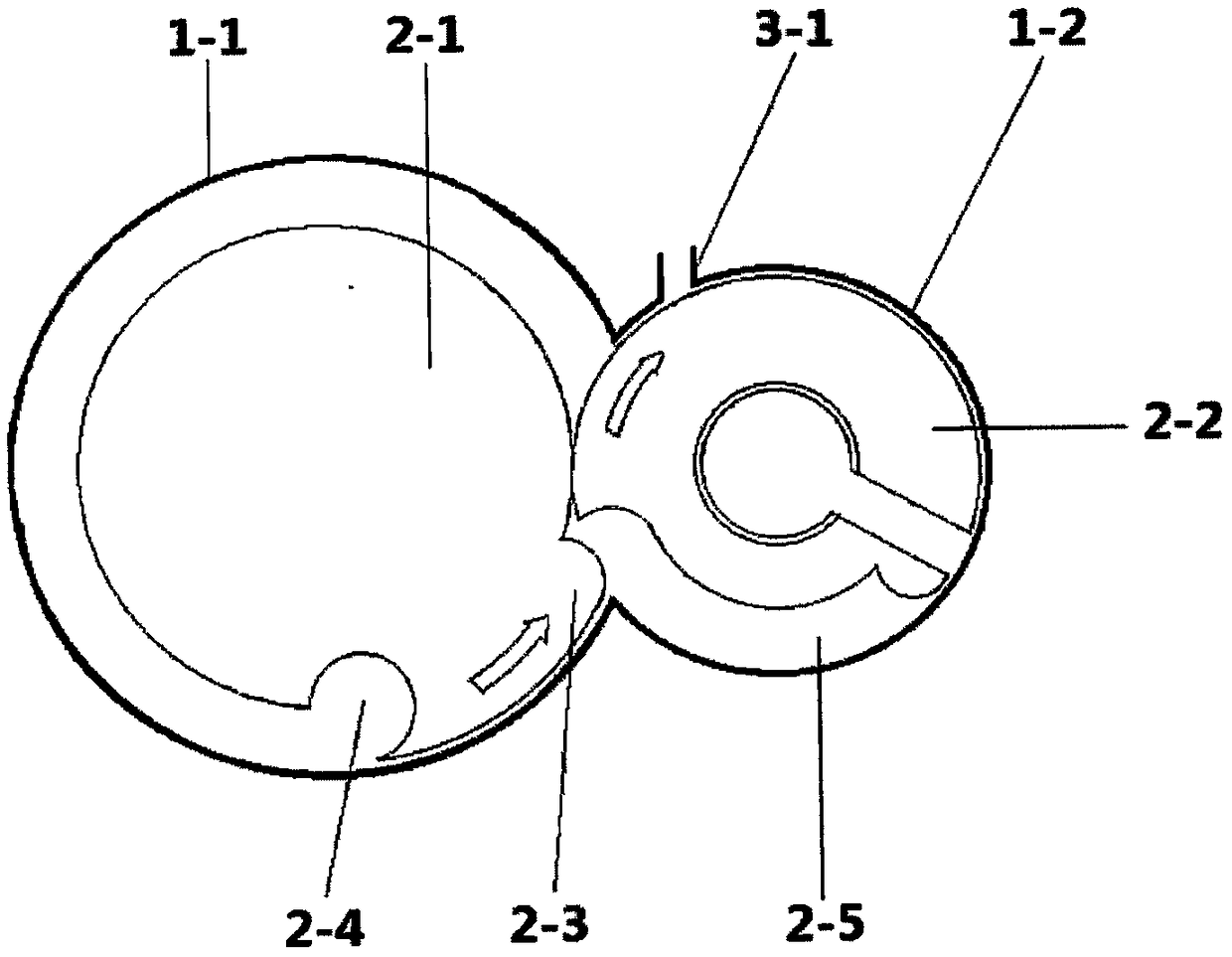

[0045] The engine includes: 1. Body system; 2. Main motion system; 3. Gas distribution system; 4. Exhaust system; 5. Fuel supply system; 6. Cooling system; 7. Lubrication system; 8. Ignition system; 9. Electric control system; some parts in these systems have applied the new technology product of prior art, and some part is the new part structure of the present invention, and their structure, position connection relation are:

[0046] 1. The body system includes a cylinder block and a cylinder head. These two pieces are innovative improvements of the present invention. They constitute the casing of the engine. The cylinder block and the cylinder head are combined by screws, and then fixed on the engine bracket by screws. The engine bracket is made separately for general small agricultural engines, and there are autocratic brackets for automobiles, boats, airplanes, etc. The components of other systems are all set around the main system according to the principles of convenience...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com