Temperature sensor encapsulation structure

A technology of temperature sensor and packaging structure, used in thermometers, thermometer parts, instruments, etc., can solve the problem that temperature sensors cannot meet high sealing, and achieve good mechanical collision resistance, good insulation sealing, high sealing requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further illustrate the principle and structure of the patent of the present invention, the embodiments of the present invention will now be described in detail in conjunction with the accompanying drawings.

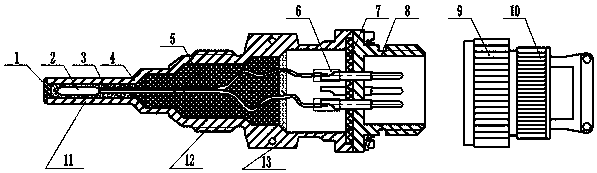

[0020] Such as figure 1 As shown, a temperature sensor packaging structure of the present invention includes a housing 4 with one end closed, and the other end of the housing 4 is fixedly connected to a sealed socket 8, and is characterized in that: it also includes a housing packaged in the housing 4 and placed The heat-sensitive element 2 at the closed end, the heat-sensitive element 2 is filled with a heat-conducting medium to form a sensor temperature measuring probe 11, the heat-sensitive element 2 is connected to the sealed socket 8 through a transitional wire, and the airtight connection with the sensor temperature measuring probe 11 The cavity is filled with epoxy 5 to form a thermal conduction channel through which the excessive wires pass.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com