Bearing assembly

A bearing assembly, bearing technology, applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve problems such as bearing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

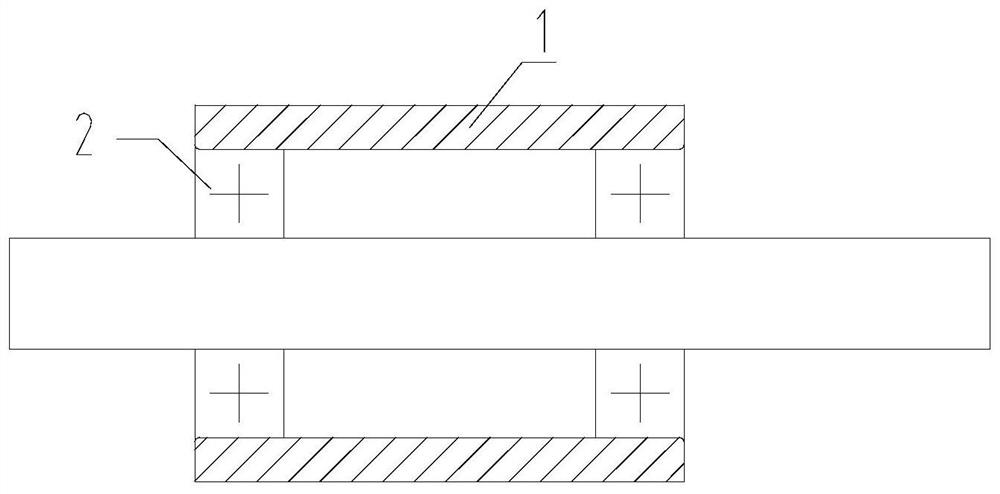

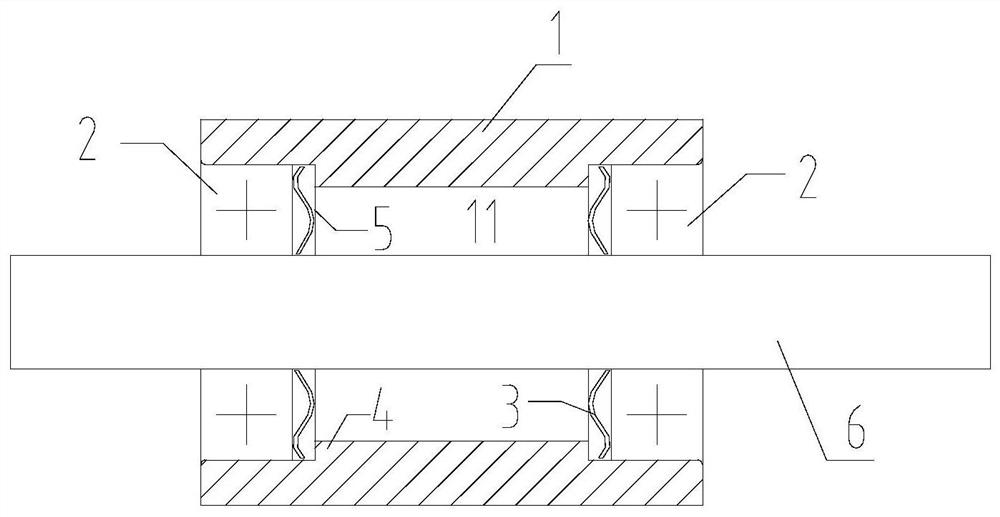

[0035] This embodiment provides a bearing assembly, such as figure 2 As shown, it includes: a bearing chamber 1 with a housing chamber 11 inside; two sets of bearings 2 relatively fixed at both ends of the housing chamber 11; two groups of elastic members 3 respectively arranged on the inner side of the bearing 2 , the accommodating cavity 11 is provided with a raised portion 4 at least at a position corresponding to the inner end surface of the bearing 2, and the elastic member 3 is arranged between the raised portion 4 and the inner surface of the bearing 2 .

[0036] In this example, if figure 2 As shown, the two groups of bearings 2 located on the left and right sides are respectively arranged at the left and right ends of the accommodation cavity 11 , and the outer end surfaces of the bearings 2 and the outer end surfaces of the bearing chamber 1 are flush with each other. In this embodiment, the bearing 2 is tensioned and arranged on the inner wall of the bearing cha...

Embodiment 2

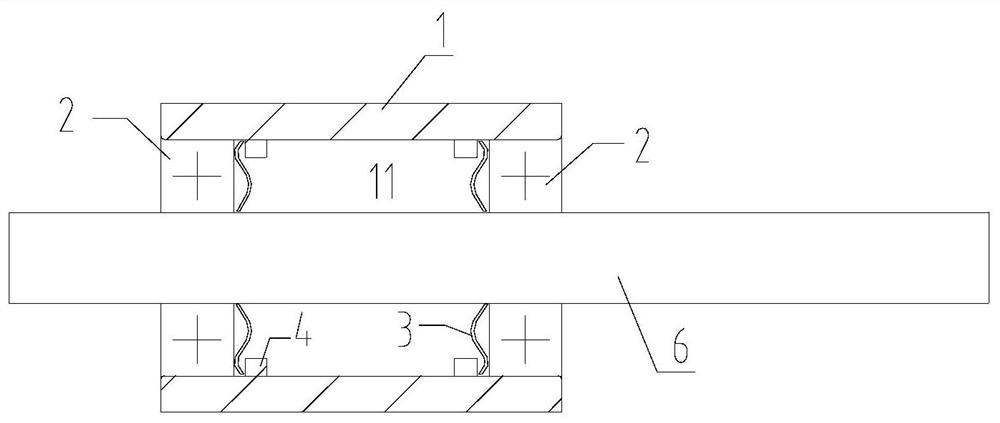

[0048] This embodiment is made on the basis of Embodiment 1. In this embodiment, another adjustment method of the preload of the elastic member 3 is provided. In this embodiment, the bearings 2 corresponding to one group The length of the protruding portion 4 is greater than the length of the protruding portion 4 corresponding to another set of the bearings 2 .

[0049] Specifically, as Figure 4 and Figure 5 As shown, the length of the raised portion 4 on the left side is longer than the length of the raised portion 4 on the right side. By limiting the length of the raised portion 4, the support force that the inner side of the bearing 2 can bear can be adjusted. . Generally speaking, when the length of the protruding part 4 is longer, its supporting force on the elastic member 3 is greater, and at this time, the pre-tightening force that the elastic member 3 itself can provide is also greater. By controlling the length of the protruding portion 4, it is possible to well ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com