Axis shifting type ballast direct shearing instrument

A technology of direct shearing instrument and crushing stone, which is applied in the direction of applying a stable shearing force to test the strength of materials, so as to achieve the effect of ensuring accuracy, easy disassembly and assembly, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

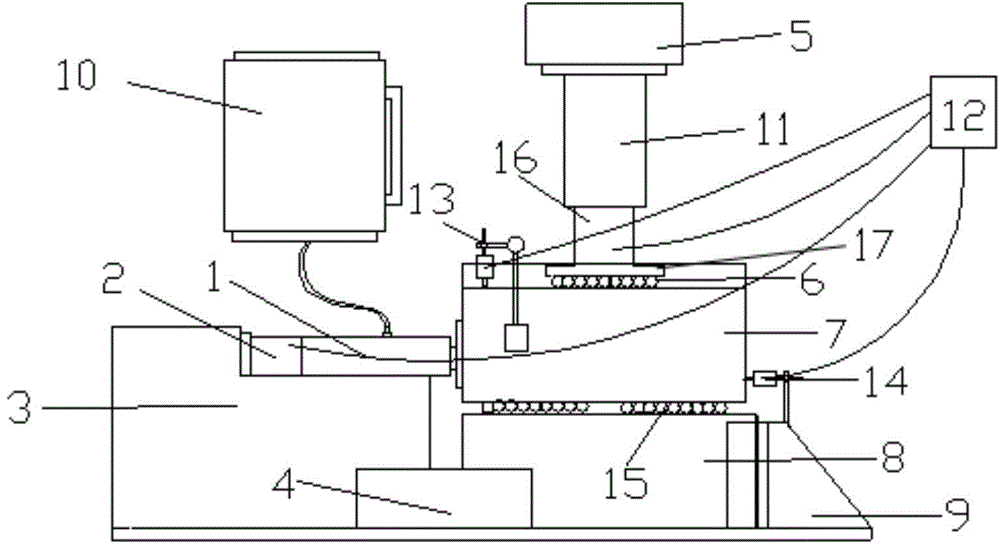

[0025] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The vertical direction in the present invention refers to the direction perpendicular to the reaction beam, and the horizontal direction refers to the direction parallel to the reaction beam.

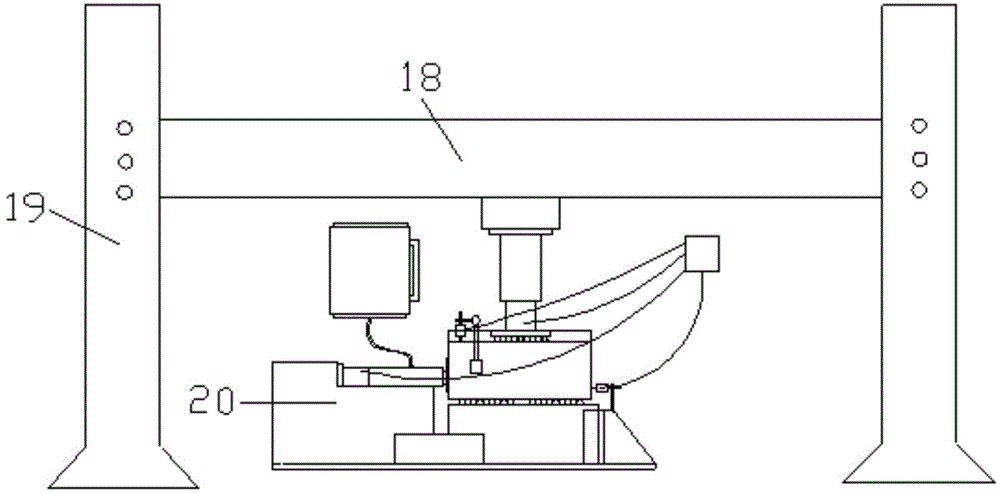

[0026] The invention provides a shaft-moving direct ballast shearer for crushed stone. The direct ballast shearer for gravel is designed using the design principle of moving the shaft up to ensure that the ballast in the shear box is disturbed to a minimum. Such as figure 1 As shown, the direct shear apparatus includes a reaction force augmentation frame and a direct shear apparatus main body 20 arranged inside the reaction force augmentation frame. The reaction force reinforcement frame includes at least two vertical columns 19 and the reaction force crossbeam 18 that is horizontally arranged on the top of the column 19, so the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com