Ultrasonic testing block group for residual stress of aluminum alloy prestretching plate and application method thereof

A residual stress, pre-stretching plate technology, applied in the preparation of test samples, material analysis using sonic/ultrasonic/infrasonic waves, measurement devices, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

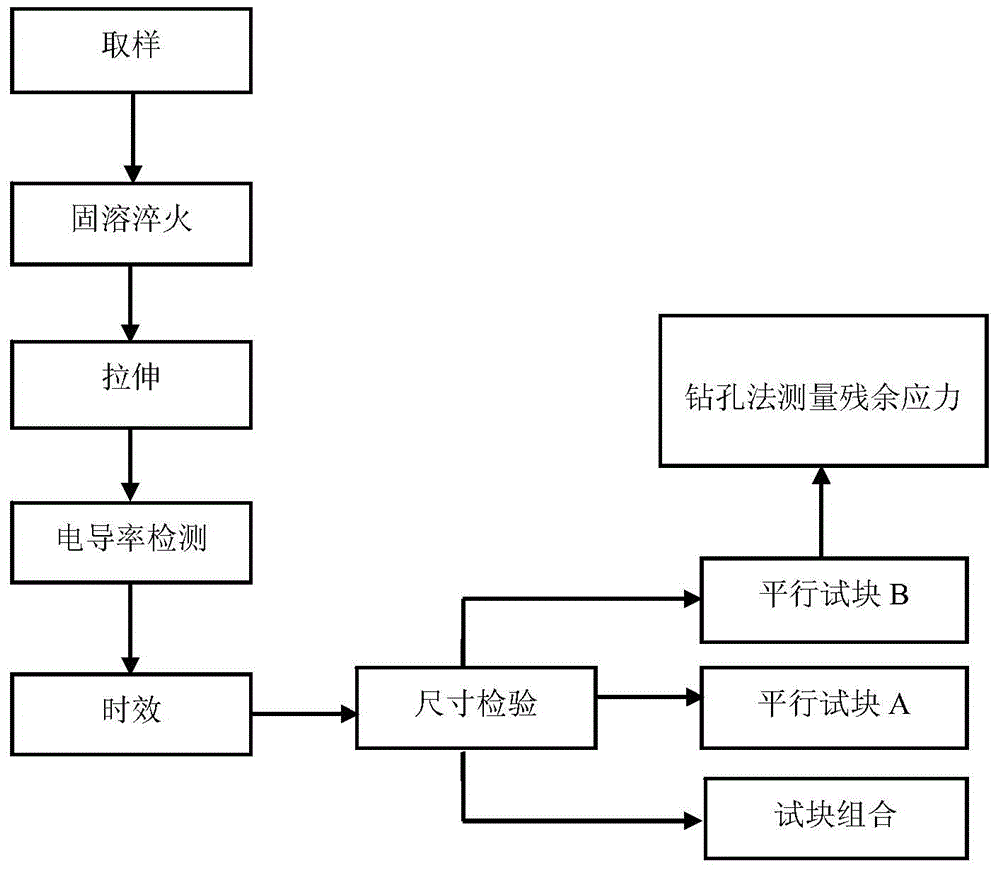

[0053] figure 1 Make a flow chart for the test block group. According to this process, the detailed preparation method of the aluminum alloy pre-stretched residual stress water immersion ultrasonic test block group is as follows:

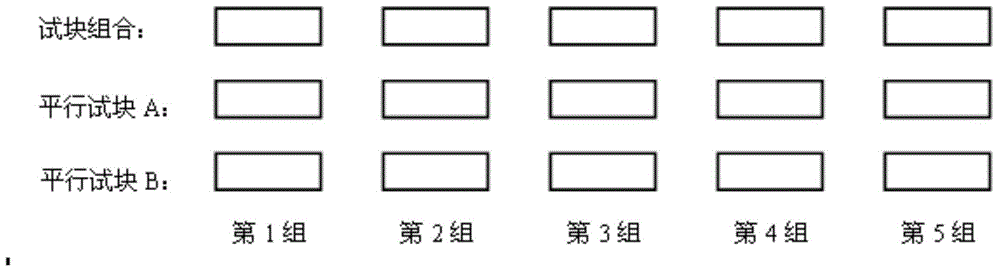

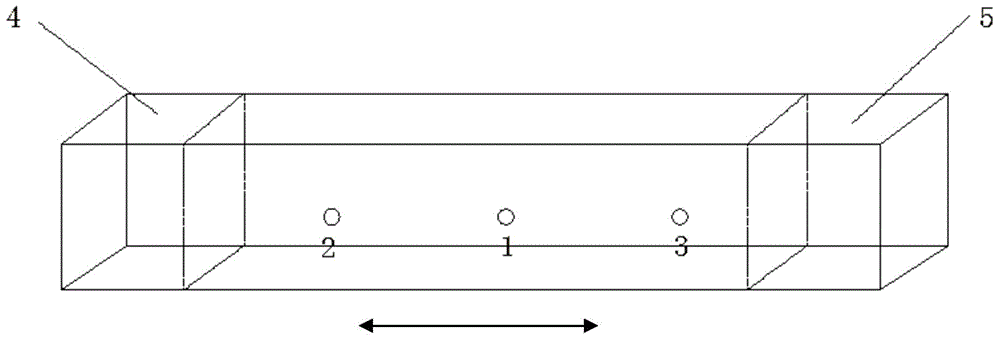

[0054] 1. Cut 15 rectangular test blocks with a width of 50 mm and a length of 405 mm from the same batch of aluminum alloy pre-stretched plates to be tested. The length direction is the same as the rolling direction of the plate. figure 2 As shown, three groups of test block combination, parallel test block A and parallel test block B are respectively obtained, and each group has 5 test blocks;

[0055] 2. Perform solution quenching on the intercepted test block;

[0056] 3. Use a conductivity meter to test the conductivity of the test block at a position with a width of 20mm and a length of 250mm. The difference in conductivity should be less than 1.5%IACS;

[0057] 4. Perform the same gradient stretching on the test block combination, paralle...

Embodiment 2

[0067] 1. Raw material acquisition:

[0068] In the same batch of 7075-T651 aluminum alloy pre-stretched plates, three groups of raw materials were intercepted, namely the test block combination, parallel test block A and parallel test block B. The length direction of the raw material is the same as the rolling direction of the plate, and a mark is provided on the surface of the raw material and the rolling surface of the tested plate in the same direction. Each group of raw materials contains 5 pieces, and the specification of each piece is 50mm in thickness, 300mm in width and 2100mm in length.

[0069] 2. Raw material processing:

[0070] Put the three groups of raw materials into a roller hearth quenching furnace for solution treatment, heat from room temperature to 470°C, hold for 2 hours, and then perform quenching treatment. Within 30 minutes, each group of raw materials was transferred to the pre-stretching machine for stretching treatment with different stretching r...

Embodiment 3

[0081] A batch of pre-stretched aluminum alloy plates were tested using the test block prepared in Example 2. The value of residual stress obtained after ultrasonic testing of a plate is 55MPa based on the above-mentioned color scale, but the customer requires that the residual stress in the rolling direction of the plate detected by the drilling method should be less than 50MPa. Therefore, This piece of board was judged to be scrapped.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com