Shallow sea submarine cable laying technology based on mooring system and dynamic positioning

A submarine cable laying and mooring system technology, applied in cable installation, ground cable installation, etc., to achieve the effects of low energy consumption, improved propulsion efficiency, and large load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

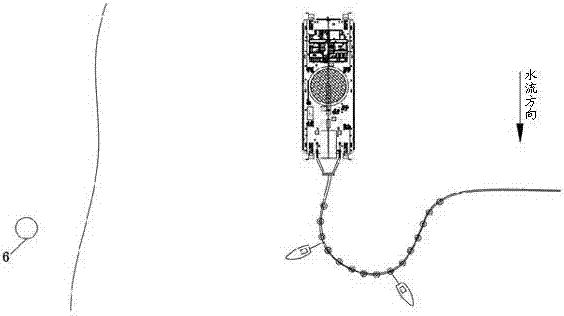

[0023] A shallow sea submarine cable laying process based on mooring system and dynamic positioning, using a flat square barge 1 as the cable laying ship ( figure 1 ), has the characteristics of shallow draft, large waterline area, large load capacity, and can be grounded on mud flats and intertidal zones. It is suitable for submarine cable laying operations in shallow seas.

[0024] The submarine cable ship of the present invention adopts a double-bottom design to ensure that the beach operation does not affect the safety of the ship.

[0025] Such as figure 2 As shown, four full-rotation power rudder paddles 2 are installed on the four corners of the cable-laying ship. Through the rudder paddles on the four ship corners, the power propulsion adjustment of the cable-laying ship is carried out in real time, and the position of the cable-laying ship i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com